Surface corrosion preventing treatment method based on aluminum profiles

A technology of anti-corrosion treatment and aluminum profiles, which is applied to the surface coating liquid device, spraying device, coating, etc., can solve the problems of uneven coating on the surface of aluminum profiles, low work efficiency, and inability to ensure uniform coating spraying, etc., to achieve Reduce work intensity and working time, reduce waste of resources, safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

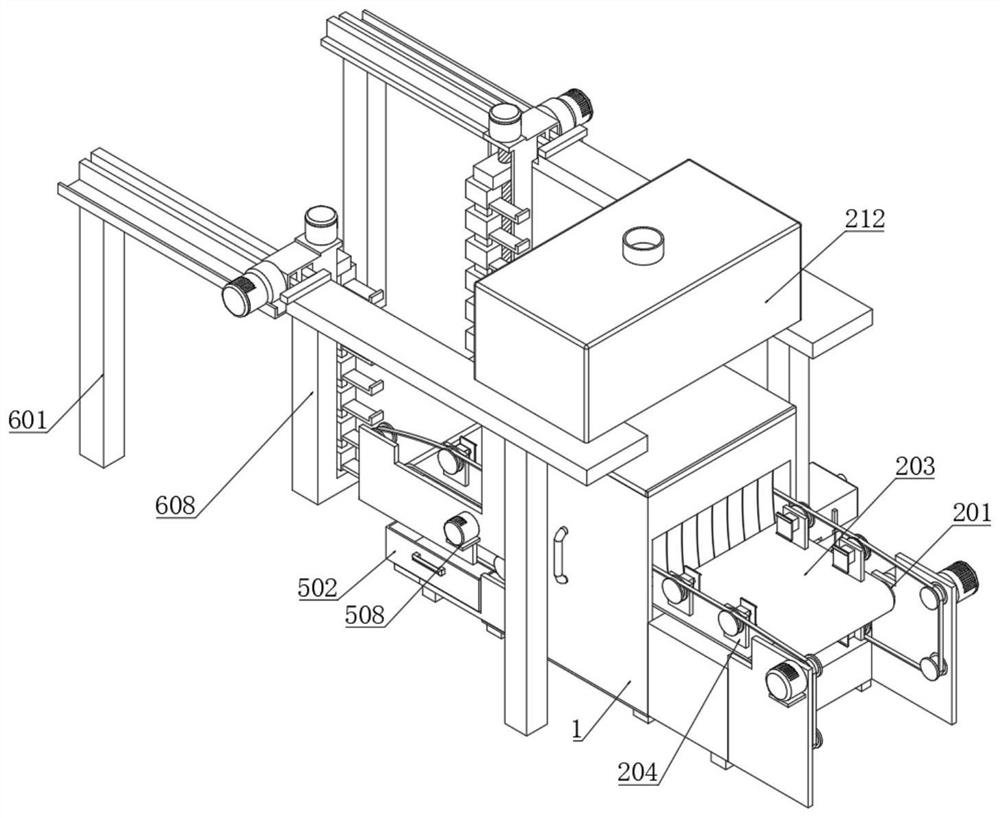

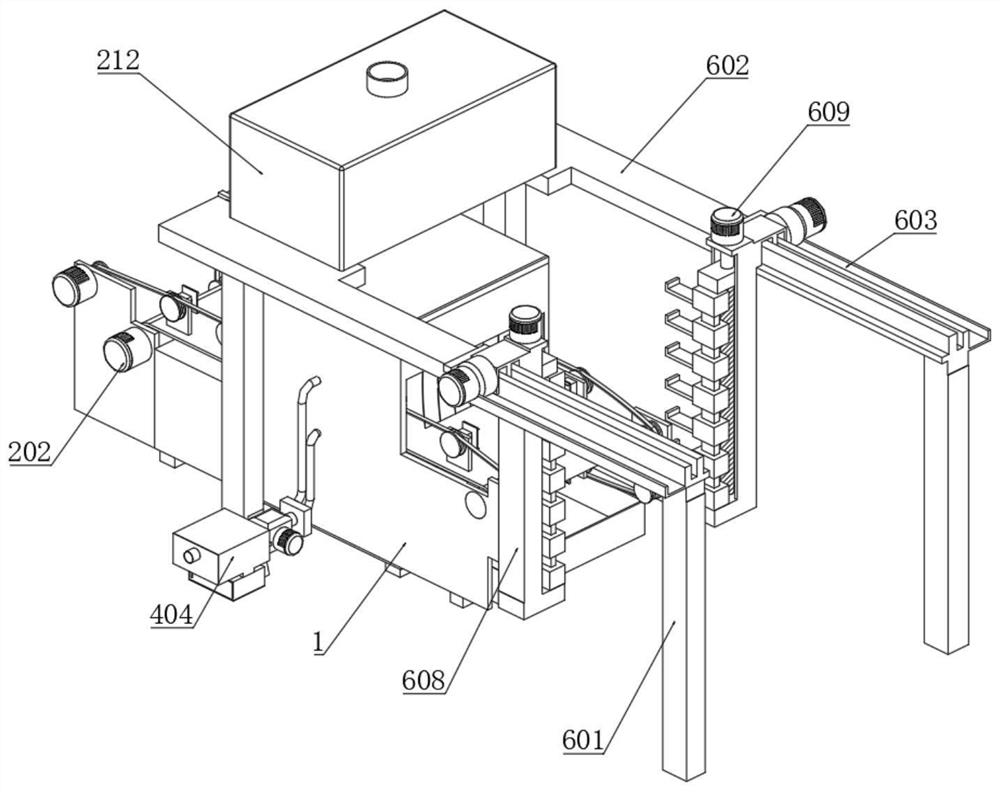

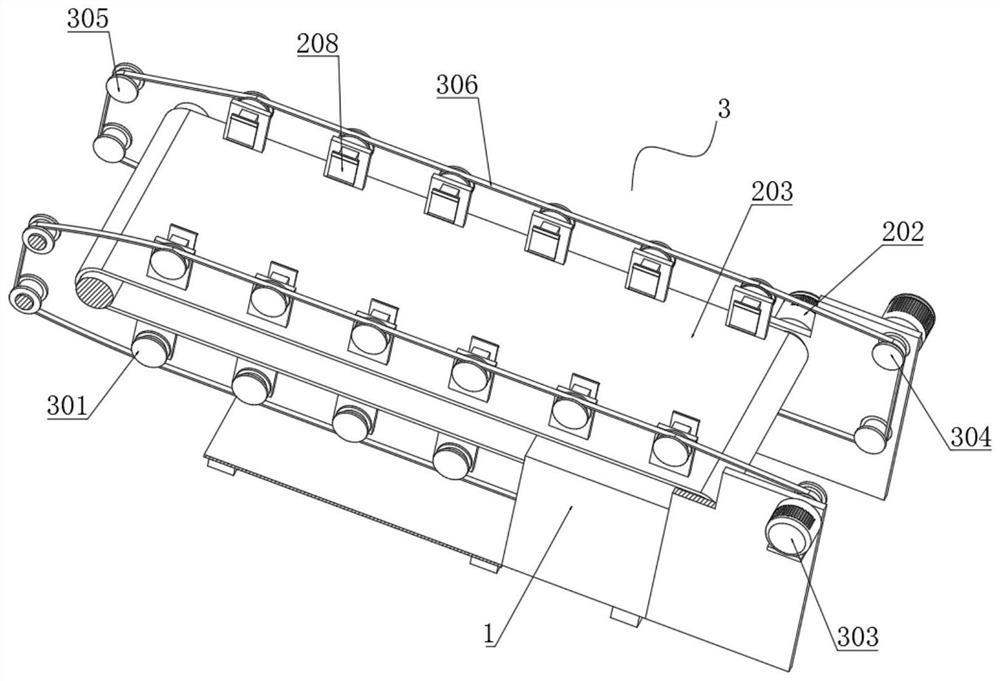

[0061] Such as Figure 1-9 As shown, the present invention provides a technical solution, the surface anti-corrosion treatment device includes a treatment body 1, the inside of the treatment body 1 is equipped with a spray anti-corrosion treatment mechanism 2, and the inside of the treatment body 1 is fixed at one side of the spray anti-corrosion treatment mechanism 2 A rotating mechanism 3 is installed, and an adsorption mechanism 4 is fixedly installed at one end of the bottom of the processing body 1. A cleaning mechanism 5 is installed inside the processing body 1 at a position below the spraying anti-corrosion processing mechanism 2. The top of the processing body 1 is installed at an end away from the spraying machine 2. Conveying mechanism 6;

[0062] Spraying anti-corrosion treatment mechanism 2 comprises conveying shaft 201, conveying motor 202, conveyer belt 203, anti-corrosion rubber mount 204, rotating rod 205, fixed block 206, extruding spring 207, extruding plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com