Processing device for fireproof cable with metal sheath

A technology for fire-resistant cables and processing devices, which can be used in devices for coating liquids on surfaces, cable/conductor manufacturing, circuits, etc. Improve fire performance, clear organization and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

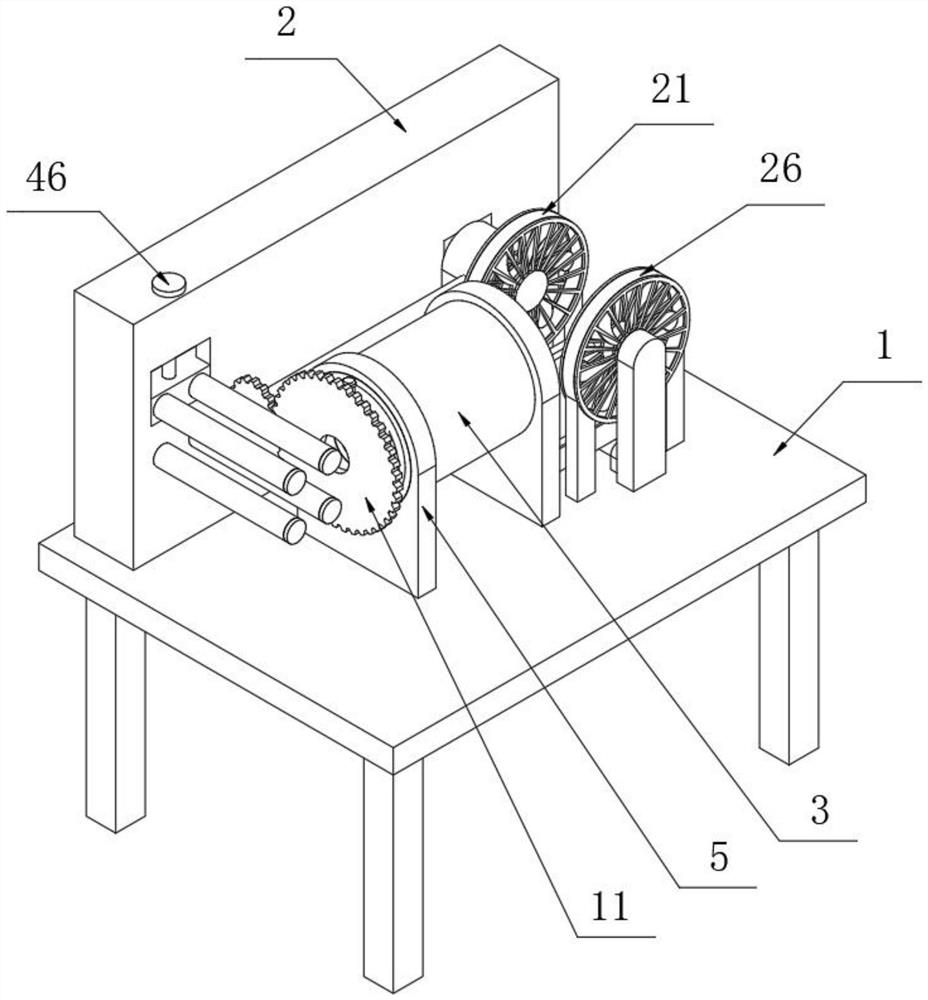

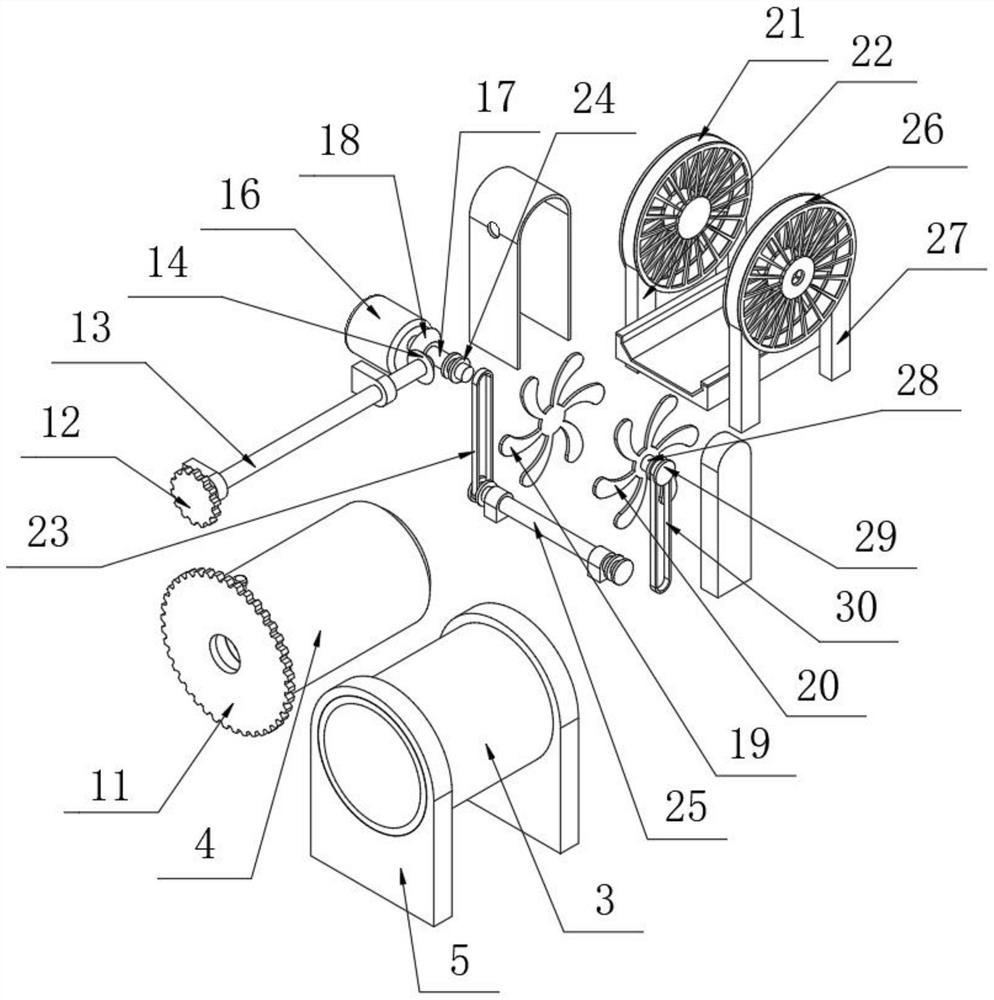

[0043] Refer to attached Figure 1-7 , a fireproof cable processing device with a metal sheath provided by the present invention includes a processing table 1, a fixed vertical plate 2 is fixedly connected to one side of the top of the processing table 1, and a limit processing is provided on one side of the fixed vertical plate 2 mechanism;

[0044] The limit processing mechanism includes a limit sleeve 3 and an annular sleeve 4, the limit sleeve 3 is located on one side of the fixed riser 2, and both ends of the limit sleeve 3 are provided with support risers 5, The two ends of the limiting sleeve 3 respectively pass through two supporting vertical plates 5 and are fixedly connected with the supporting vertical plates 5. The supporting vertical plate 5 is fixedly connected with the processing table 1, and the annular sleeve 4 is positioned on the limiting sleeve. 3 and is movably socketed with the limiting sleeve 3, one end of the limiting sleeve 3 is fixedly connected with...

Embodiment 2

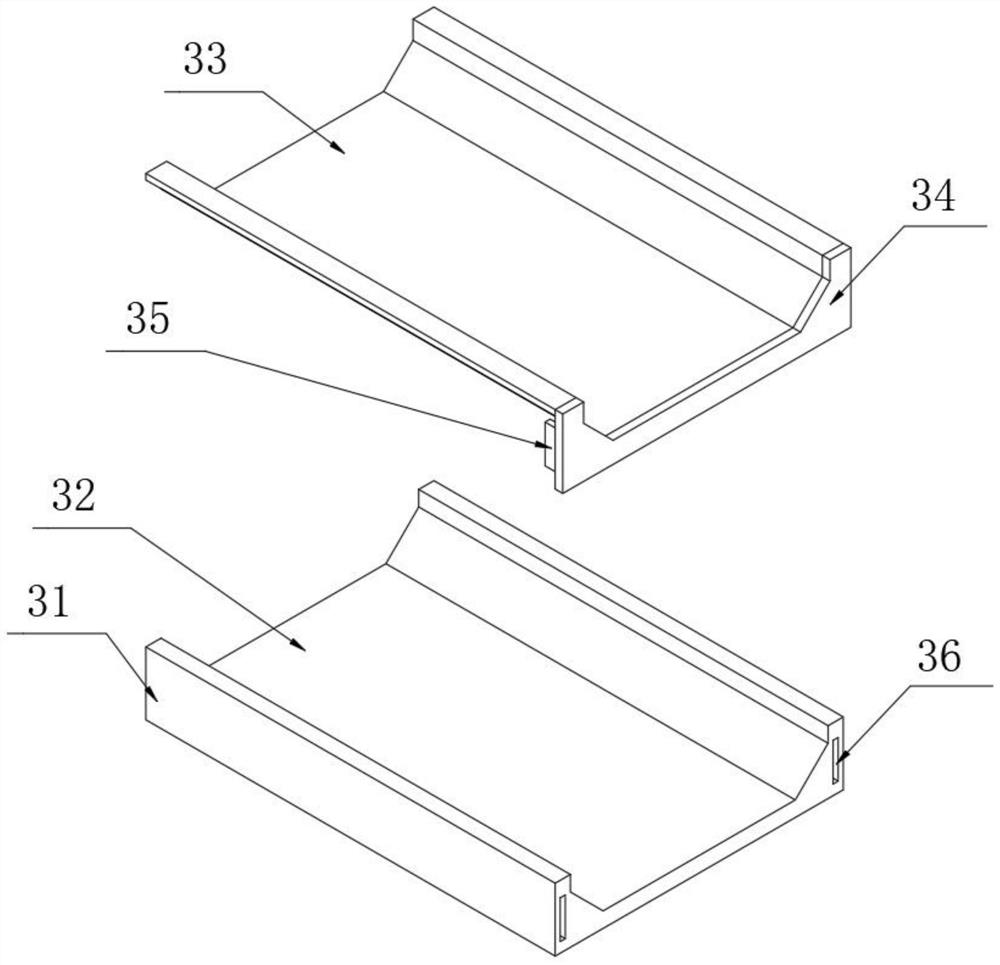

[0052] Refer to attached Figure 8 , a fireproof cable processing device with a metal sheath provided by the present invention, the limit sleeve 3 is provided with a movable positioning assembly near the end of the ring gear 11, and the movable positioning assembly includes a fixed horizontal shaft 39 and a limiting horizontal shaft 40, the surface of the end of the fixed vertical plate 2 away from the motor 16 is provided with a sliding vertical groove 41, and the inner bottom of the sliding vertical groove 41 is slidably connected with a sliding protrusion 42, and the number of the fixed horizontal shaft 39 and the limit horizontal shaft 40 Both are set to two, and the two limit horizontal axes 40 are respectively located at both ends of one side of the sliding protrusion 42 and are fixedly connected with the sliding protrusion 42, and the two fixed transverse axes 39 are respectively located at the two limit horizontal axes 40 bottom and is fixedly connected with the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com