Frying furnace and control method thereof

A fryer and control panel technology, which is applied in the field of induction cookers, can solve the problems of electric heaters that are easy to age and have a short lifespan, seriously affect the health of cooks, and cannot meet fire protection requirements, etc., and achieves that it is not easy to zoom and deteriorate, the energy saving effect is obvious, and the use is safe. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

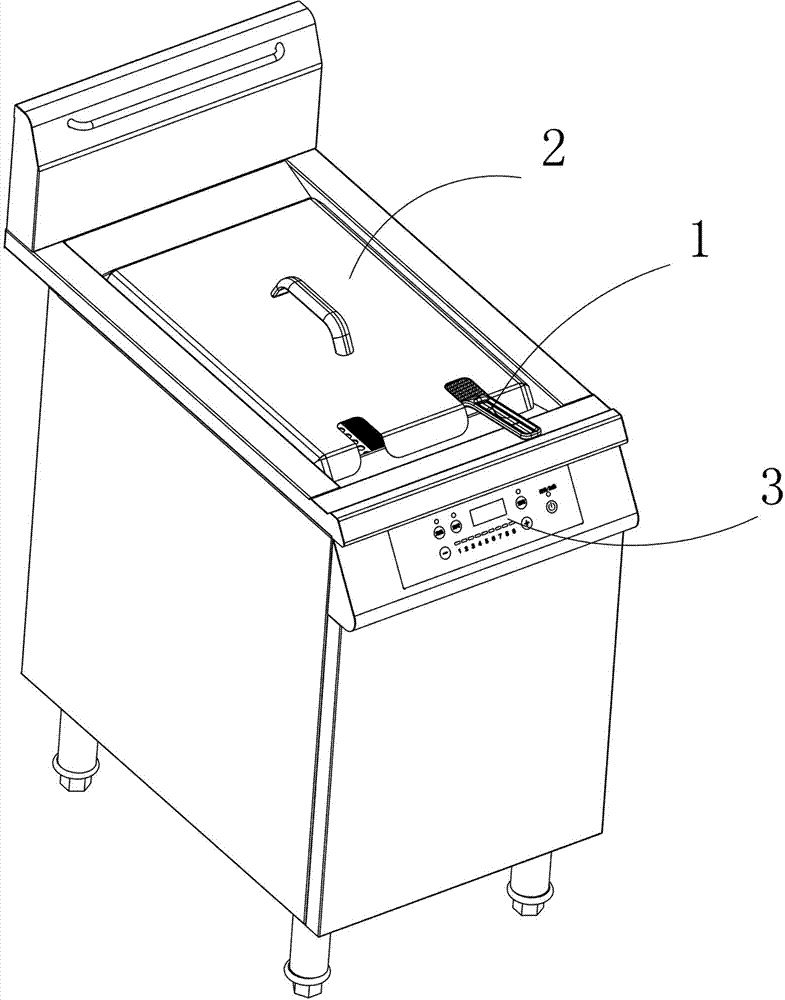

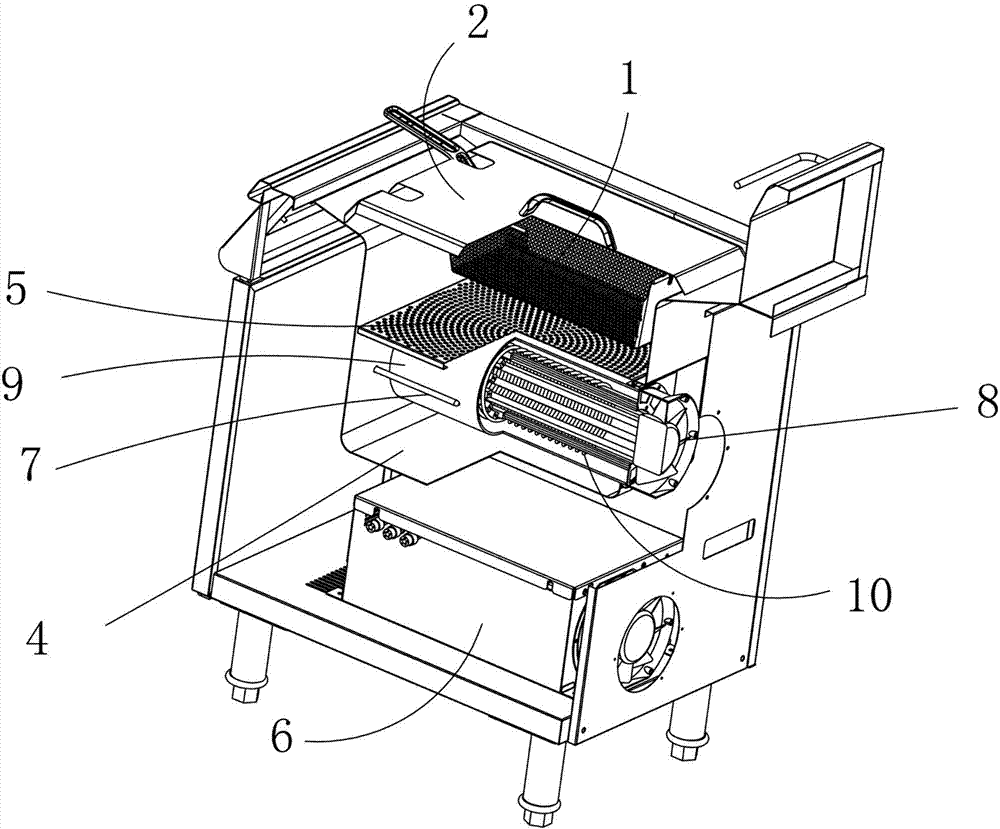

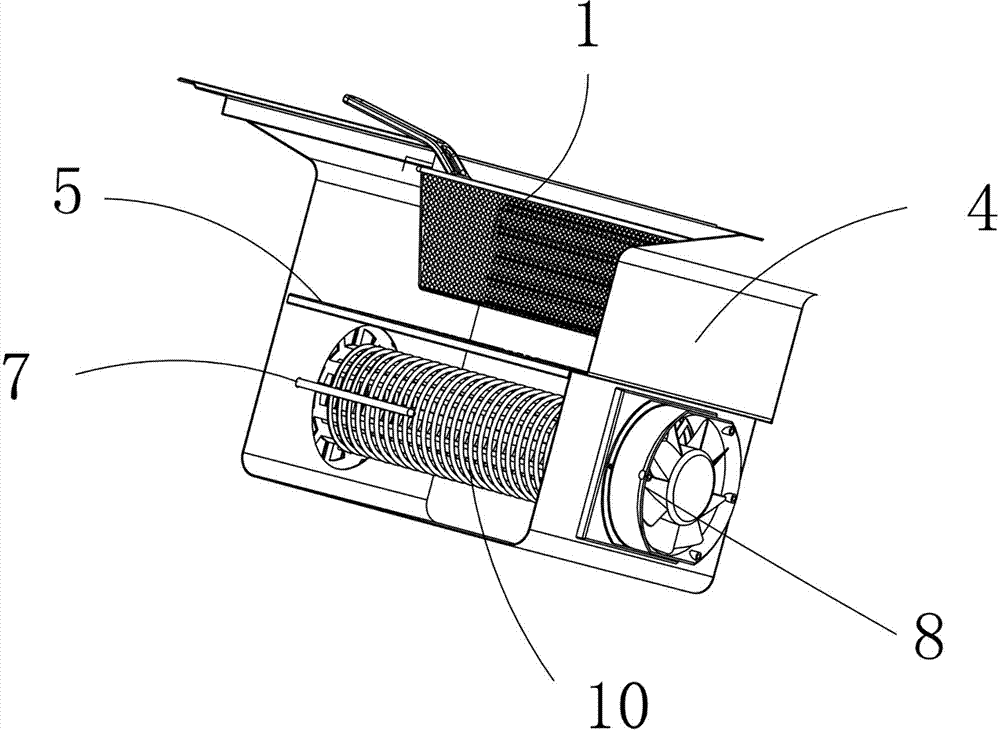

[0022] see Figure 1-3 , the present invention relates to a fryer, comprising a shell, an oil pan 4, a fryer 1 for containing food, a cover 2 is placed above the fryer, and the fryer 1 is placed in the upper oil body of the oil pan 4. The lower part of the oil pan is suspended with a hollow metal cylinder 9, and the hollow metal cylinder is opened on the outside of the oil pan. An electromagnetic coil disk 10 is arranged in the hollow metal cylinder, and a heating core 6 is also arranged in the shell. The heating core supplies an alternating current to the electromagnetic coil disk 10 .

[0023] A control panel 3 is arranged on the shell of the fryer, and a switch button and an input module are arranged on the control panel, and the control panel is connected with the heating core 6 in communication.

[0024] The hollow metal cylinder is made of 430 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com