Hot pressing mechanism

A technology of hot-pressing mechanism and heat insulating material, which is applied in presses, optics, instruments, etc., can solve the problems of poor heating efficiency of hot-pressing mechanism and damage to substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

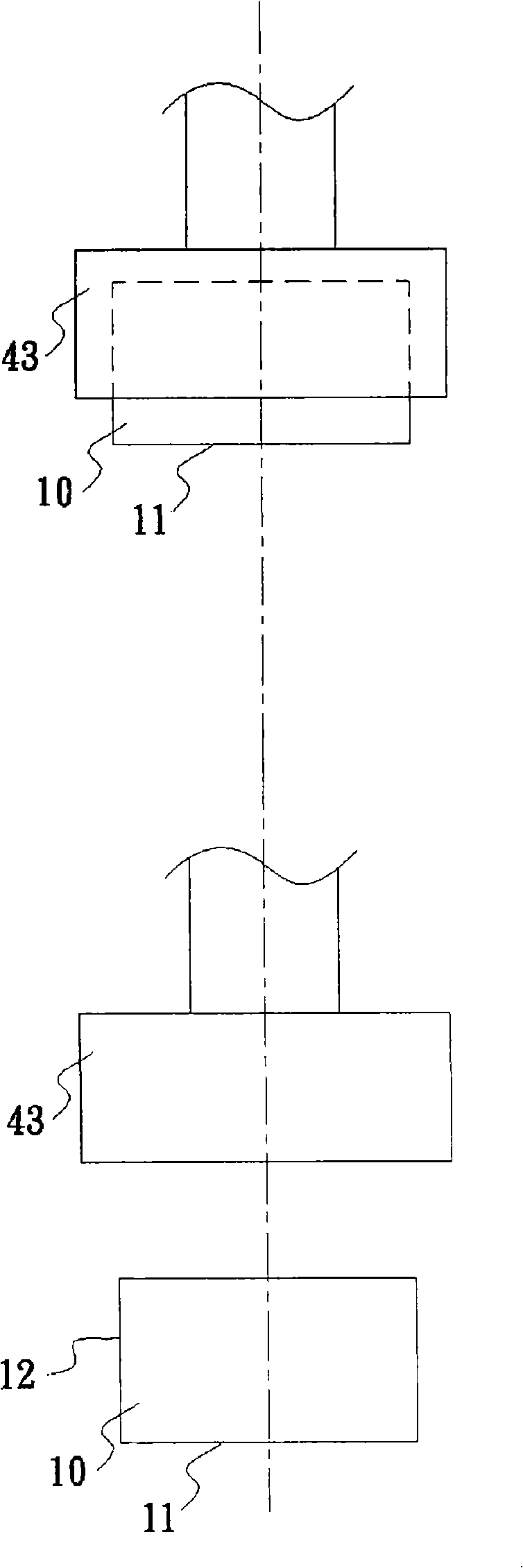

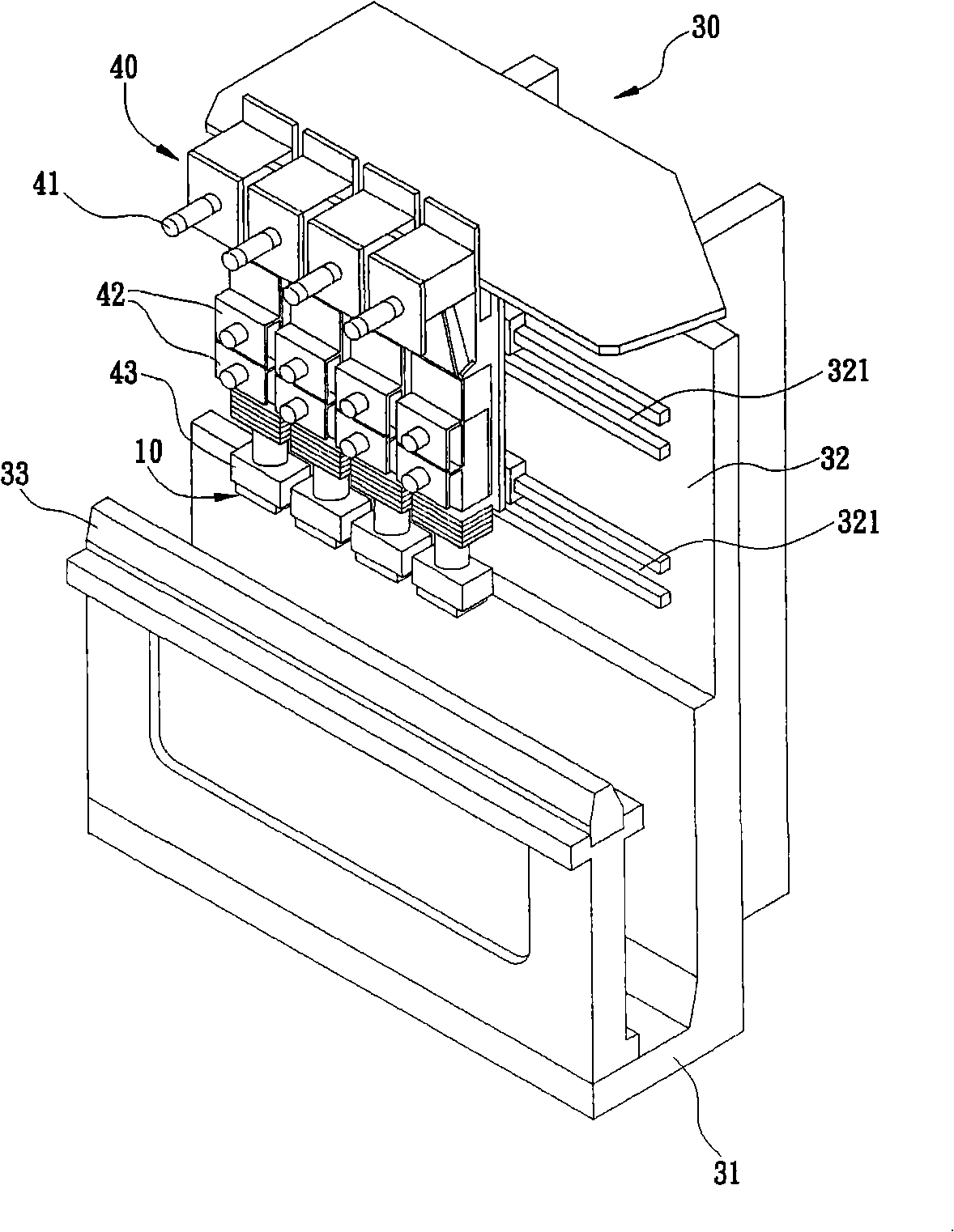

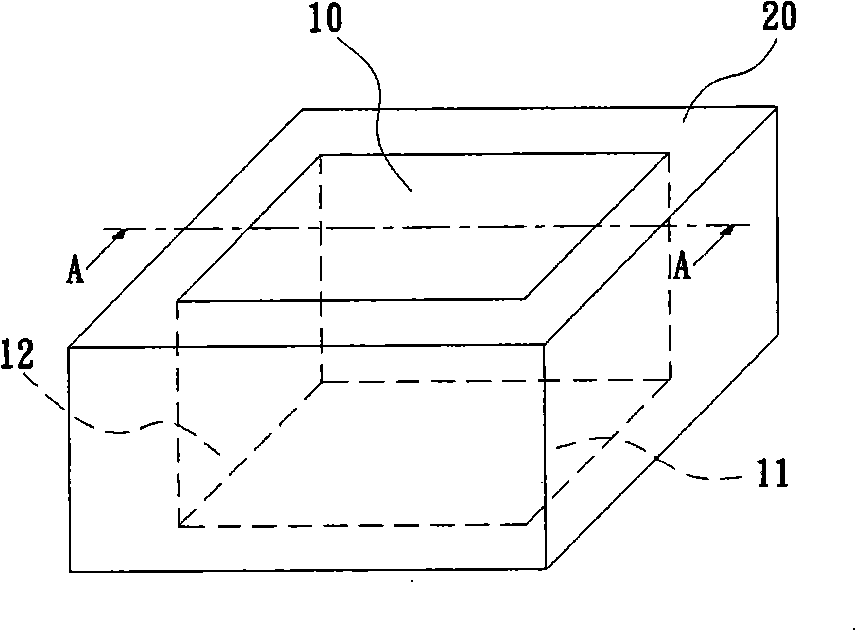

[0034] like figure 2 , Figure 3A and Figure 3B Shown is a heat-pressing mechanism disclosed in the first embodiment of the present invention, including: a heat-pressing head 10 , a heat insulating material 20 , a heating platform 30 and a transmission device 40 . The heating platform 30 is placed on the ground as a main supporting structure. The transmission device 40 is connected to the heating platform 30 to drive the thermal pressing head 10 to move so as to change the position of the thermal pressing head 10 on the heating platform 30 .

[0035] see Figure 3A and Figure 3B , the thermal pressing head 10 has a pressing surface 11 and a side wall 12 , wherein the side wall 12 is adjacent to the pressing surface 11 and surrounds the edge of the pressing surface 11 . The thermal pressing head 10 is used to generate high temperature after being heated, and the pressing surface 11 contacts the solder or the welding piece to be hot-pressed, so as to heat the solder or t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com