Induction heating apparatus

An induction heating device and a technology to be heated, applied in the direction of induction heating device, induction heating, process efficiency improvement, etc., can solve the problems of inability to completely suppress the heating of the spiral copper tube and the reduction of magnetic flux, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

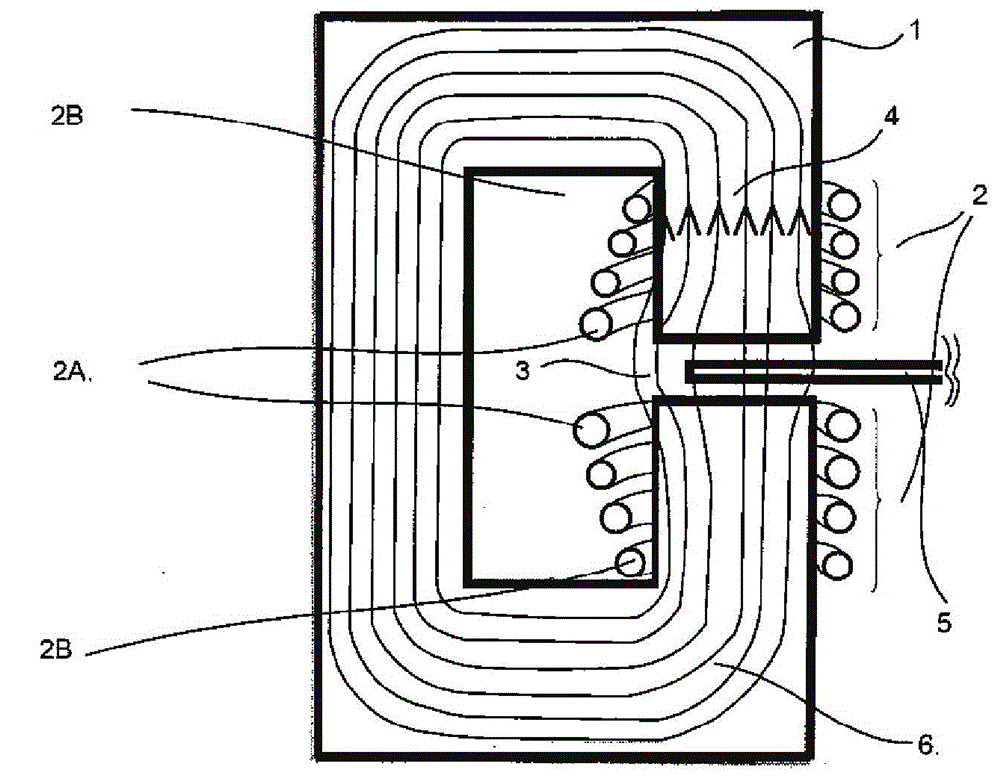

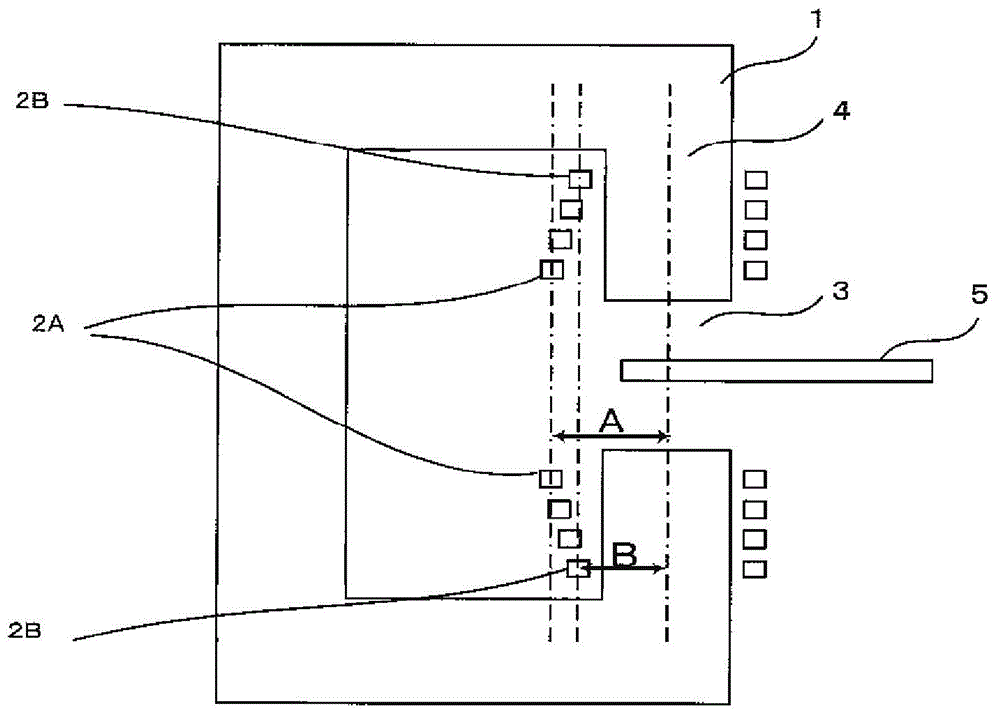

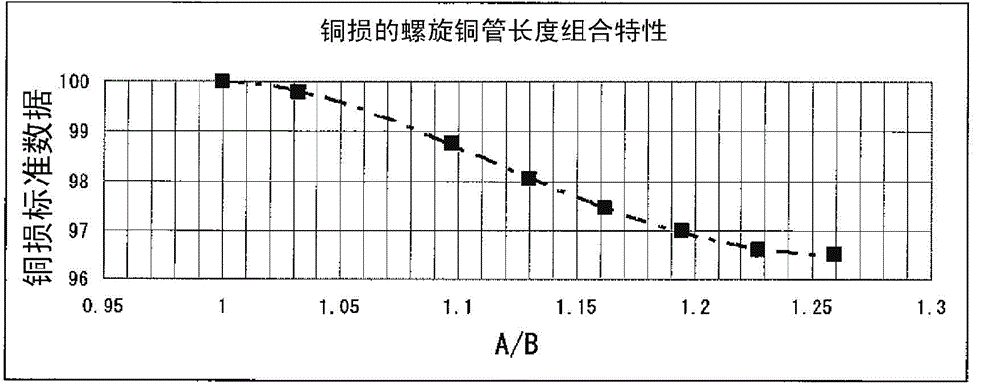

[0024] figure 1 It is a front view showing the induction heating device of the first embodiment of the present invention. Such as figure 1 As shown, a C-shaped iron core 1 is formed by laminating electromagnetic steel sheets, and spiral copper pipes 2 are respectively wound around the upper and lower core legs 4 sandwiching the opening 3 of the C-shaped iron core 1 to form an inductor. The spiral copper tube 2 is a heating coil. The end of the heated member 5 passes through the opening 3, and the heated member 5 is inductively heated by the magnetic flux 6 penetrating the inside of the C-shaped core 1 up and down to form a loop.

[0025] The induction heating device using the C-type inductor does not have a large air gap in the path of the magnetic flux 6, and has excellent heating efficiency.

[0026] Since the heated element 5 is a non-magnetic body exceeding the Curie point, the C-type inductor tends to expand greatly in the middle of the magnetic flux 6 passing through the open...

no. 2 approach

[0035] Next, the second embodiment will be described. Figure 5 It is a front view showing the induction heating device of the second embodiment of the present invention. Such as Figure 5 As shown, in the second embodiment, a heating coil, that is, a spiral copper tube 2 is wound around the upper and lower core legs 4 sandwiching the opening 3 of the C-shaped core 1, and the C-shaped inductor is formed in the C The upper and lower core legs 4 of the type inductor are respectively formed with inclined surfaces 4a on the end sides of the surfaces facing the openings 3 through which the heated material passes. The intervals between the openings 3 are enlarged toward the inside of the C-shaped core 1.

[0036] Inclined surfaces 4a are formed on the ends of the upper and lower core legs 4 facing the openings 3, and the gaps between the openings 3 are enlarged toward the inside of the C-shaped core 1, so that the magnetic flux 6 can easily flow between the upper and lower core legs. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com