Electric automobile, power battery pulse heating system and heating method

A pulse heating and power battery technology, which is applied in electric vehicles, secondary batteries, secondary battery repair/maintenance, etc., can solve the problems of limited heating efficiency and limited use occasions, and achieve extended service life, fast temperature, and guaranteed pulse The effect of heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

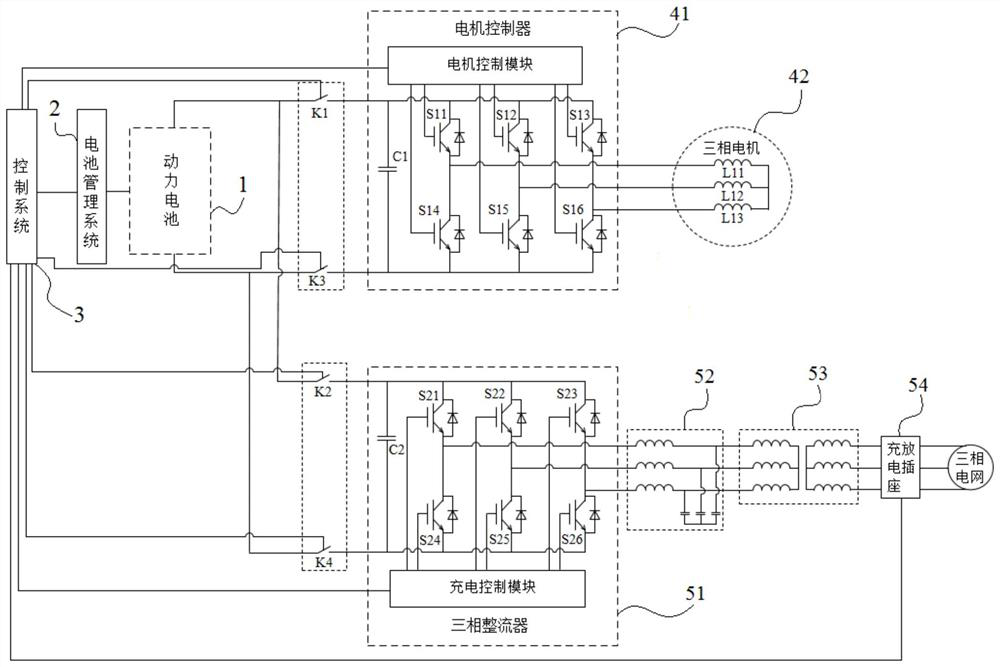

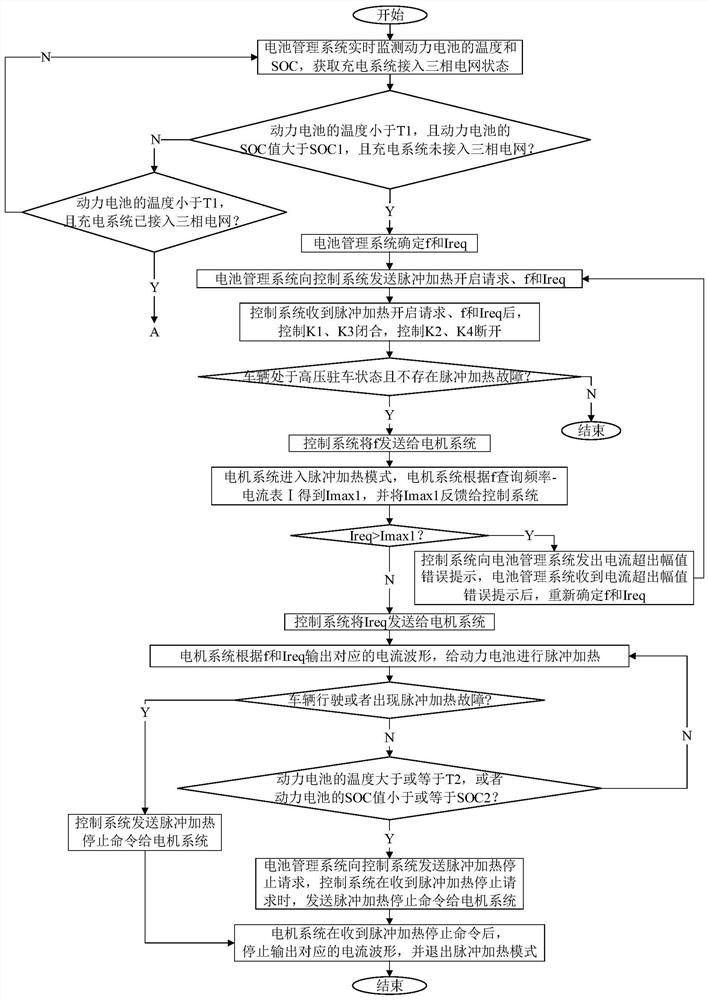

[0062] Embodiment 1: as figure 1 The power battery pulse heating system shown includes battery management system 2, control system 3, motor system, charging system, first controllable switch K1, second controllable switch K2, third controllable switch K3, fourth controllable switch Switch K4. The control terminal of the first controllable switch K1 , the control terminal of the second controllable switch K2 , the control terminal of the third controllable switch K3 and the control terminal of the fourth controllable switch K4 are connected to the control system 3 . The battery management system 2 is connected to the power battery 1. The battery management system 2 monitors the temperature and SOC of the power battery 1 in real time, and determines the pulse current frequency request value f and the pulse current magnitude request value Ireq according to the temperature of the power battery 1 . The battery management system 2 is connected to the control system 3 through a CAN ...

Embodiment 2

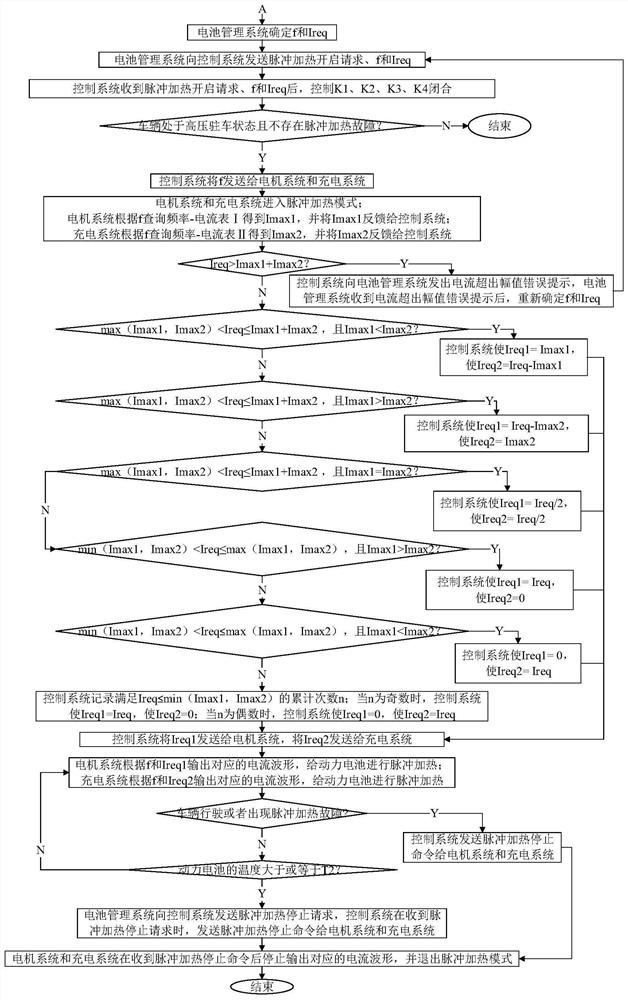

[0115] Embodiment 2: as Figure 4 The power battery pulse heating system shown includes a battery management system 2, a control system 3, a motor system, a charging system, a first three-phase controllable switch K5, and a second three-phase controllable switch K6. The control terminal of the first three-phase controllable switch K5 and the control terminal of the second three-phase controllable switch K6 are connected to the control system 3 . The battery management system 2 is connected to the power battery 1. The battery management system 2 monitors the temperature and SOC of the power battery 1 in real time. The battery management system 2 and the control system 3 are connected through the CAN line. Stop request and the temperature of the power battery, the battery management system 2 (from the control system) obtains the status of the charging system connected to the three-phase grid, and the control system 3 determines the pulse current frequency request value f and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com