Power battery pulse heating system and heating method for electric vehicle

A power battery and pulse heating technology, which is applied to electric vehicles, electric power units, power units, etc., can solve the problems of electric vehicles that are not suitable for dual motors, limited adjustable range of battery pulse current, and limited heating efficiency of battery packs. Achieve the effect of expanding the heating power, reducing the duration of a single heating, and improving the efficiency of pulse heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

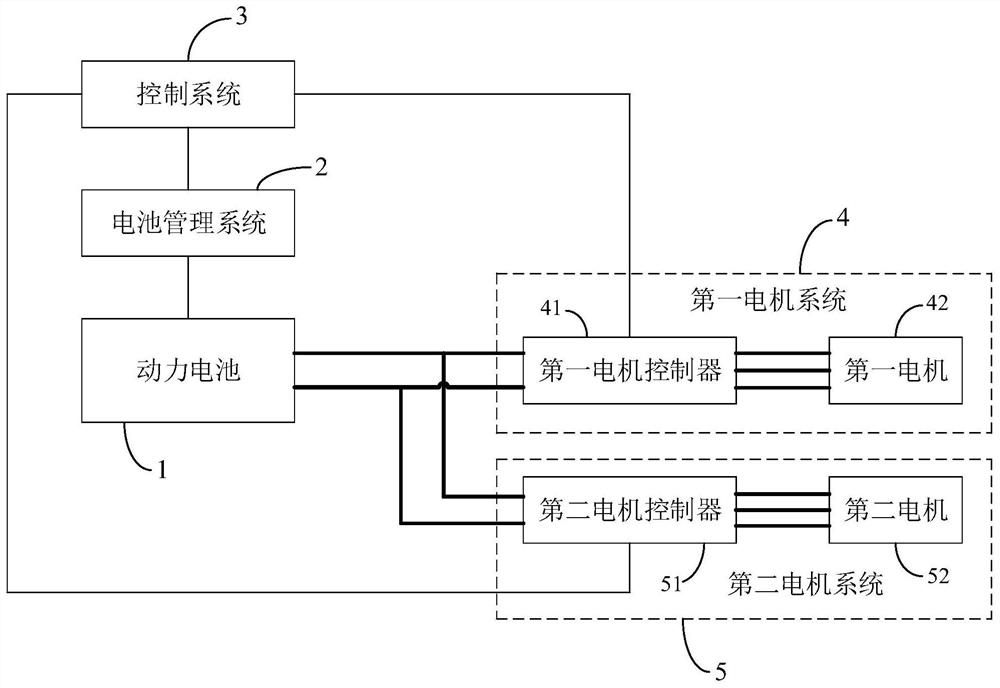

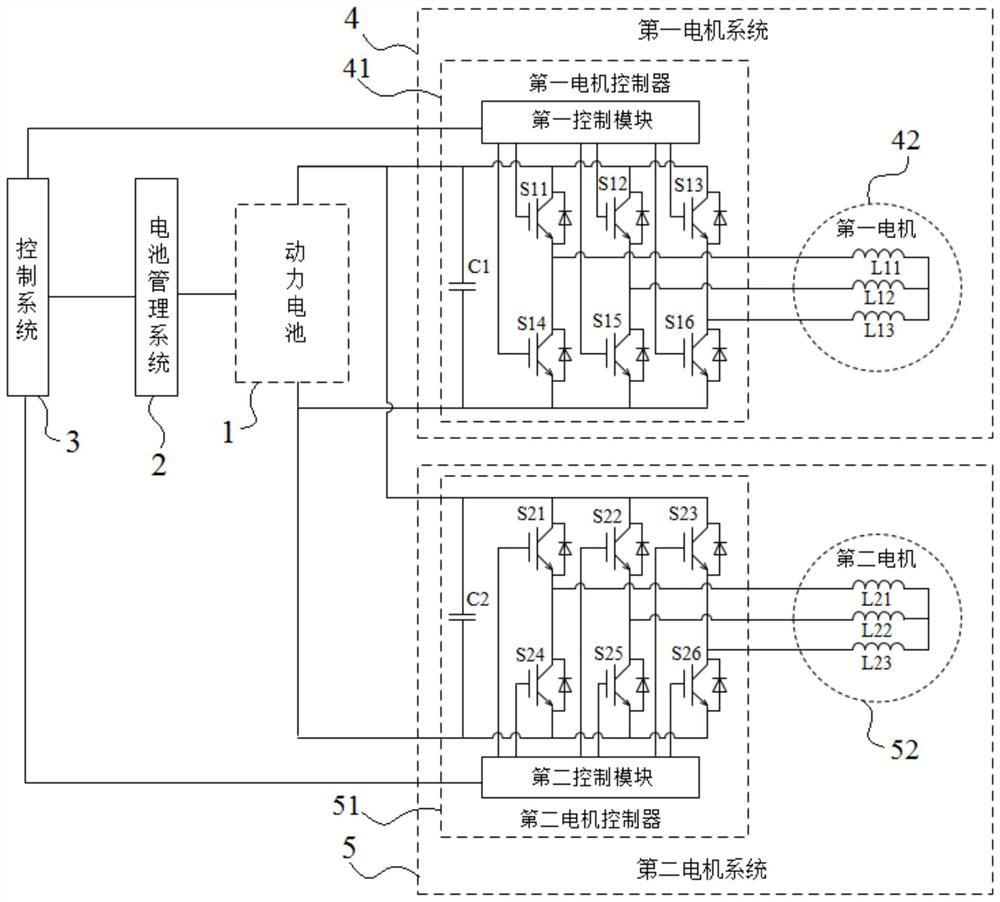

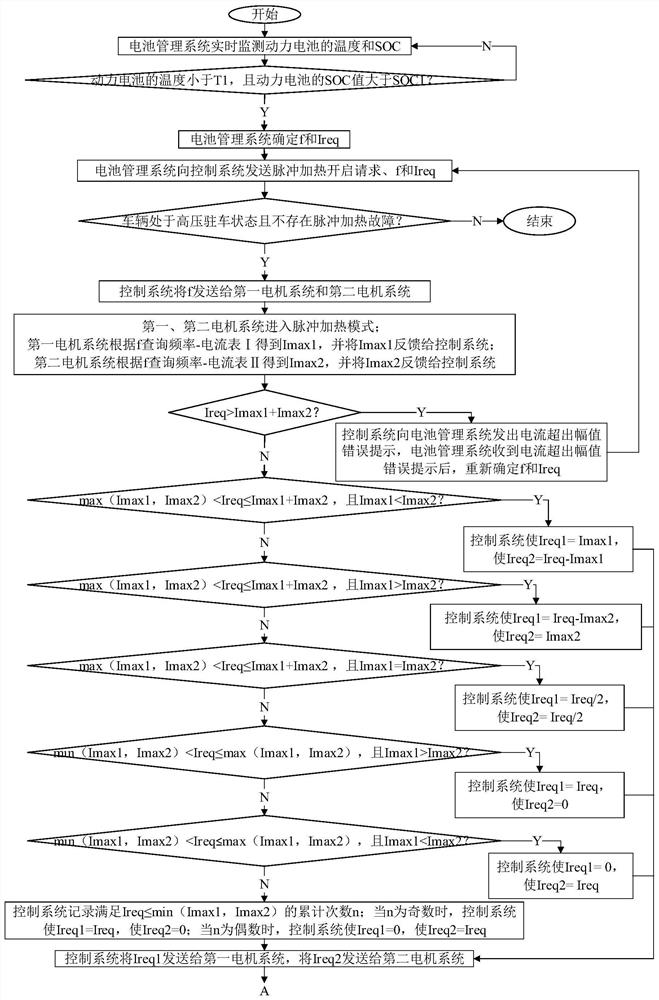

[0046] Embodiment 1: as figure 1 , figure 2 The power battery pulse heating system of the electric vehicle shown includes a battery management system 2 , a control system 3 , a first motor system 4 and a second motor system 5 . The first motor system 4 and the second motor system 5 may be a driving motor system, a generator system or other motor systems connected between the positive pole and the negative pole of the power battery. The battery management system 2 is connected to the power battery 1. The battery management system 2 monitors the temperature and SOC of the power battery 1 in real time. The battery management system 2 is connected to the control system 3. The battery management system 2 sends a pulse heating start / stop request to the control system 3. The pulse current frequency request value f and the pulse current size request value Ireq, when necessary, the control system 3 sends an error prompt to the battery management system 2 that the current exceeds the ...

Embodiment 2

[0077] Embodiment 2: as Figure 5 , Figure 6 As shown, most of the structure of the power battery pulse heating system of the electric vehicle in this embodiment is the same as that of Embodiment 1, the difference is:

[0078] The battery management system 2 sends the pulse heating start / stop request and the temperature of the power battery to the control system 3, and the control system 3 determines the pulse current frequency request value f and the pulse current magnitude request value Ireq according to the power battery temperature.

[0079] The first motor system 4 includes a first motor controller 41 and a first motor 42, as well as a first controllable switch K1, the first motor 42 is a Y-connected three-phase four-wire motor, the first motor 42 The neutral point leads connected to the first phase stator winding L11, the second phase stator winding L12, and the third phase stator winding L13 are connected to the upper end of the first bridge arm converter through the ...

Embodiment 3

[0107] Embodiment 3: as Figure 5 , Figure 9 As shown, most of the structure of the power battery pulse heating system of the electric vehicle in this embodiment is the same as that of Embodiment 1, the difference is:

[0108] The first motor system 4 includes a first motor controller 41 and a first motor 42, as well as a first controllable switch K1, the first motor 42 is a Y-connected three-phase four-wire motor, the first motor 42 The neutral point leads connected to the first phase stator winding L11, the second phase stator winding L12, and the third phase stator winding L13 are connected to the lower end of the first bridge arm converter through the controlled end of the first controllable switch K1. The seven control output terminals of the control module are respectively connected to the control terminal of the power switch S11 of the upper bridge arm, the control terminal of the power switch S12 of the upper bridge arm, the control terminal of the power switch S13 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com