Pressurizing toggle joint punching machine

A technology of toggle and punch presses, applied in the field of pressurized toggle presses, which can solve problems such as slow running speed of equipment, short ejection strokes, and locked punches, so as to improve production efficiency, increase ejection strokes, and increase driving force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

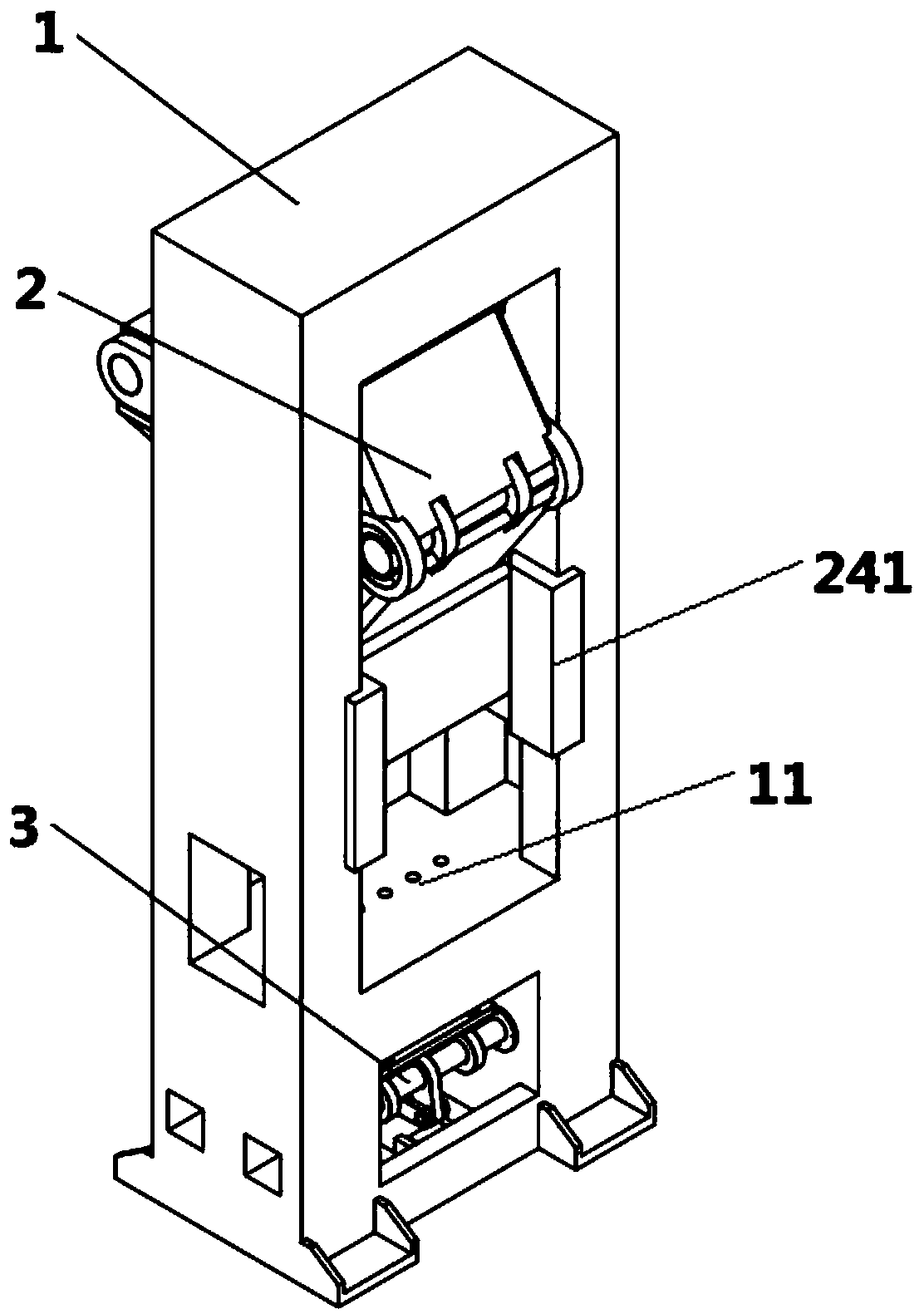

[0037] Such as figure 1 As shown, a pressurized toggle press includes a frame 1, a slider assembly 2 and an ejector assembly 3, and the slider assembly 2 is arranged on the frame 1 opposite to the ejector assembly 2, and the The frame 1 is provided with a through hole 11 through which the jacking assembly 2 protrudes.

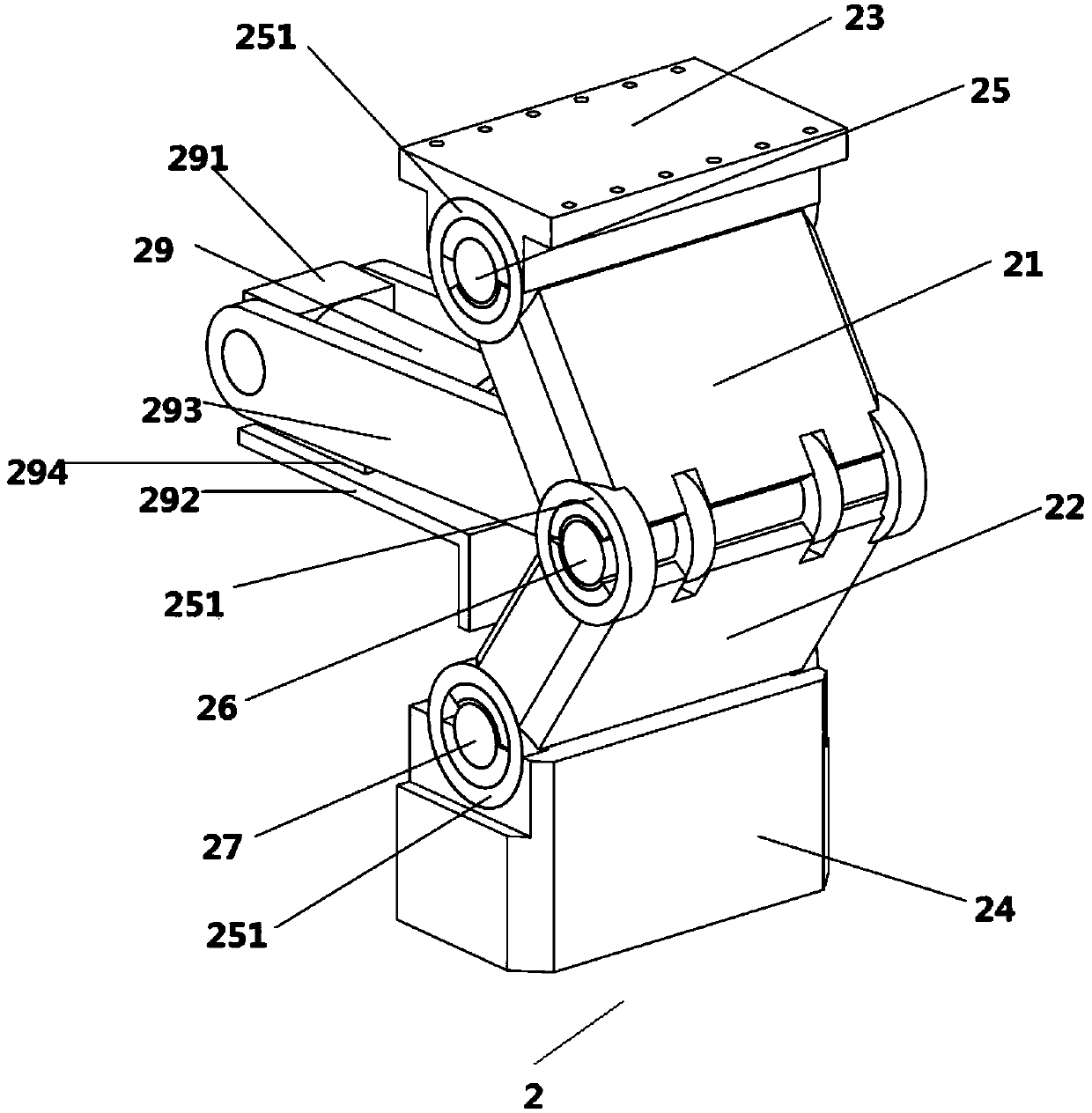

[0038] The slider assembly 2 includes an upper toggle 21, a lower toggle 22, a toggle holder 23 and a slider 24, the upper toggle 21 is fixed with the frame 1 through an upper shaft 25, and the lower toggle 22 is fixed with the slider 24 through the lower shaft 27, a central shaft 26 is arranged between the upper toggle 21 and the lower toggle 22, and the central shaft 26 is connected with a driving device, and the driving device drives The upper toggle 21 and the lower toggle 22 perform telescopic movement;

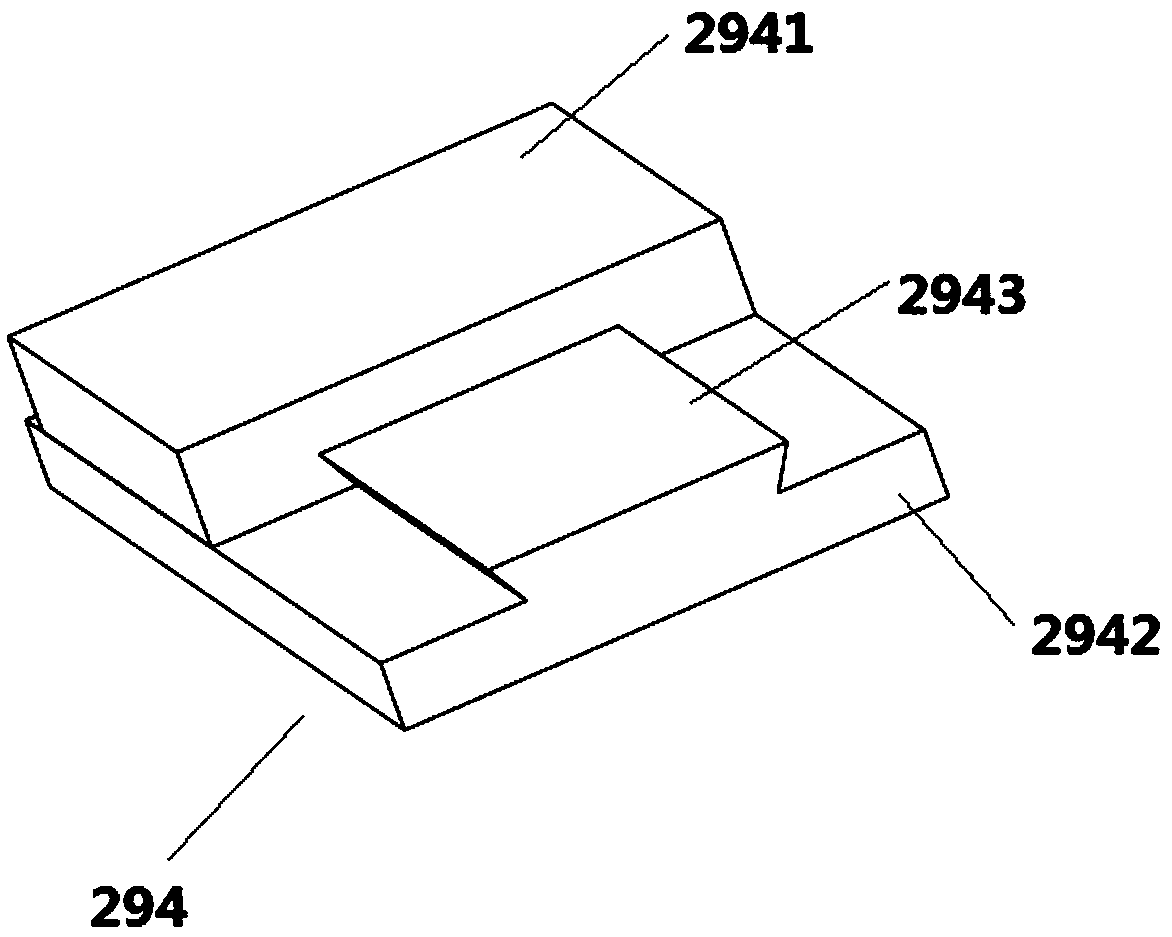

[0039] Described driving device one comprises slide block oil cylinder 29, slide block oil cylinder base 291, carriage 292 and slide rail device 294, a...

Embodiment 2

[0059] Such as Figure 12 and 13 As shown, the driving device one is a servo motor 7 in this embodiment, and the driving device one also includes a small gear 71, a large gear 72, a screw 73 and a nut 74, and the driving device also includes a servo motor base, a bracket 292 and Slide rail device 294, the servo motor 7 is arranged on the bracket 292, the bracket 292 is fixedly connected with the frame 1, the servo motor is matched with an effective gear 71, and the pinion 71 is connected to the The large gear 72 meshes, and then the rotation of the large gear 72 can be driven when the servo motor 7 drives the small gear 71 to rotate. The big gear 72 is connected with a screw 74 , the screw 74 is connected with the central shaft 26 , and the slide rail device 294 is arranged between the bracket 292 and the slider oil cylinder base 291 .

[0060] When the driving device is the servo motor 7, the motion mode is: the servo motor 7 drives the pinion 71, the pinion 71 drives the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com