Crimping Tool

a technology of crimping tool and crimping die, which is applied in the direction of stripping off devices, basic electric elements, electrical equipment, etc., can solve the problems of work piece breaking free from the crimping contour, and achieve the reduction of the geometrical moment of inertia, the effect of avoiding the deformation of the crimping contour, and reducing the force required for removing the work piece from the crimping die halves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

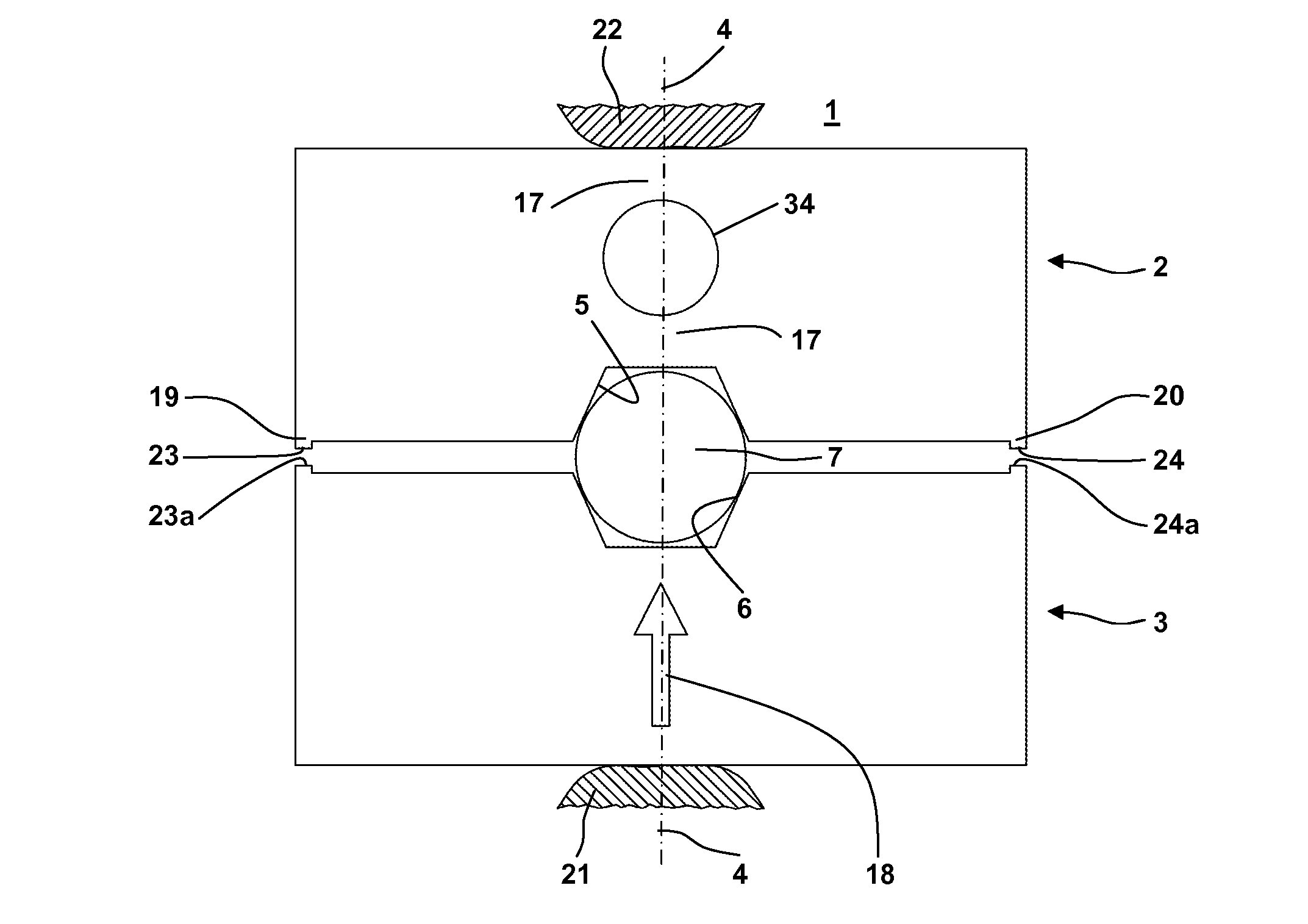

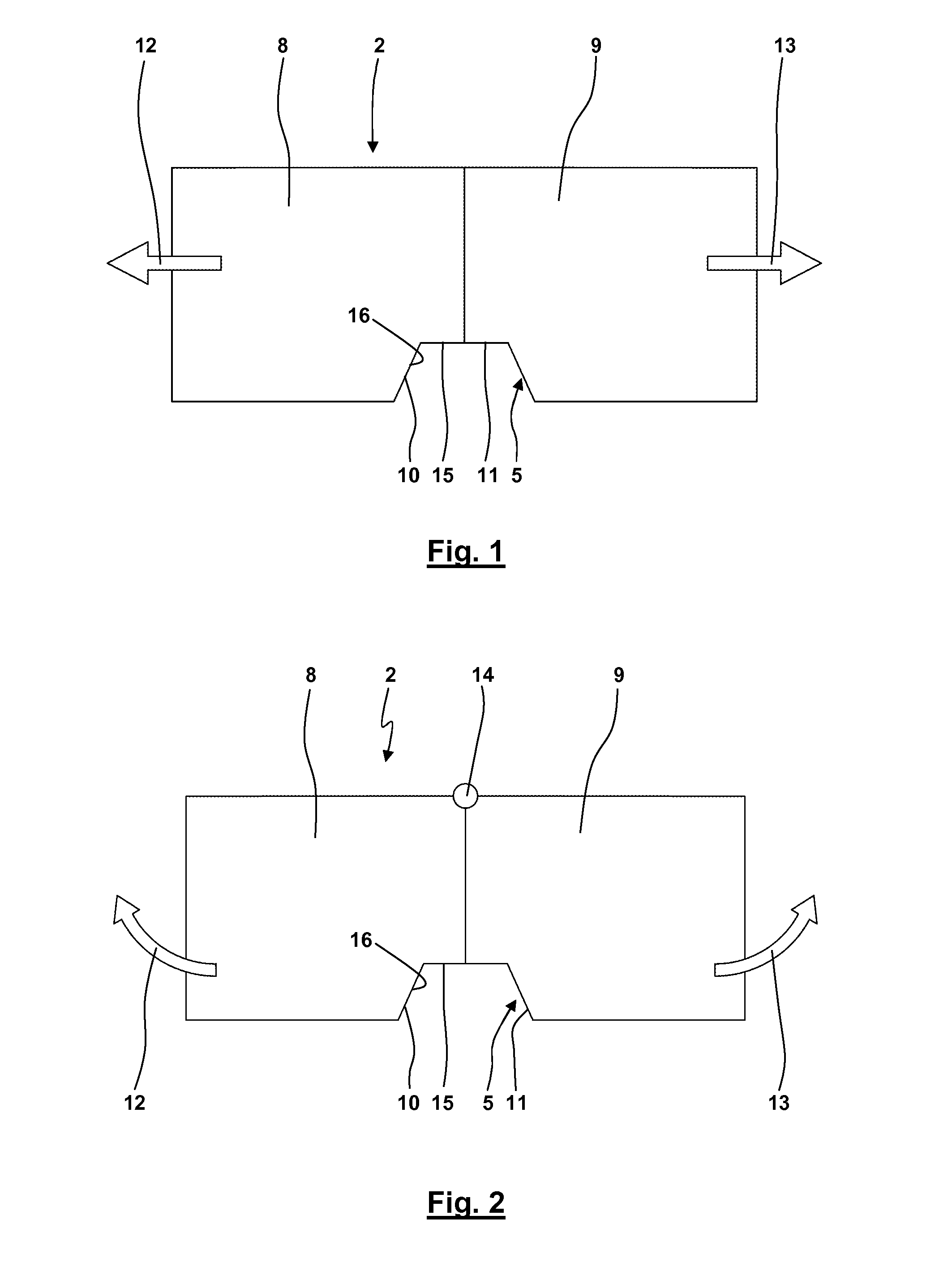

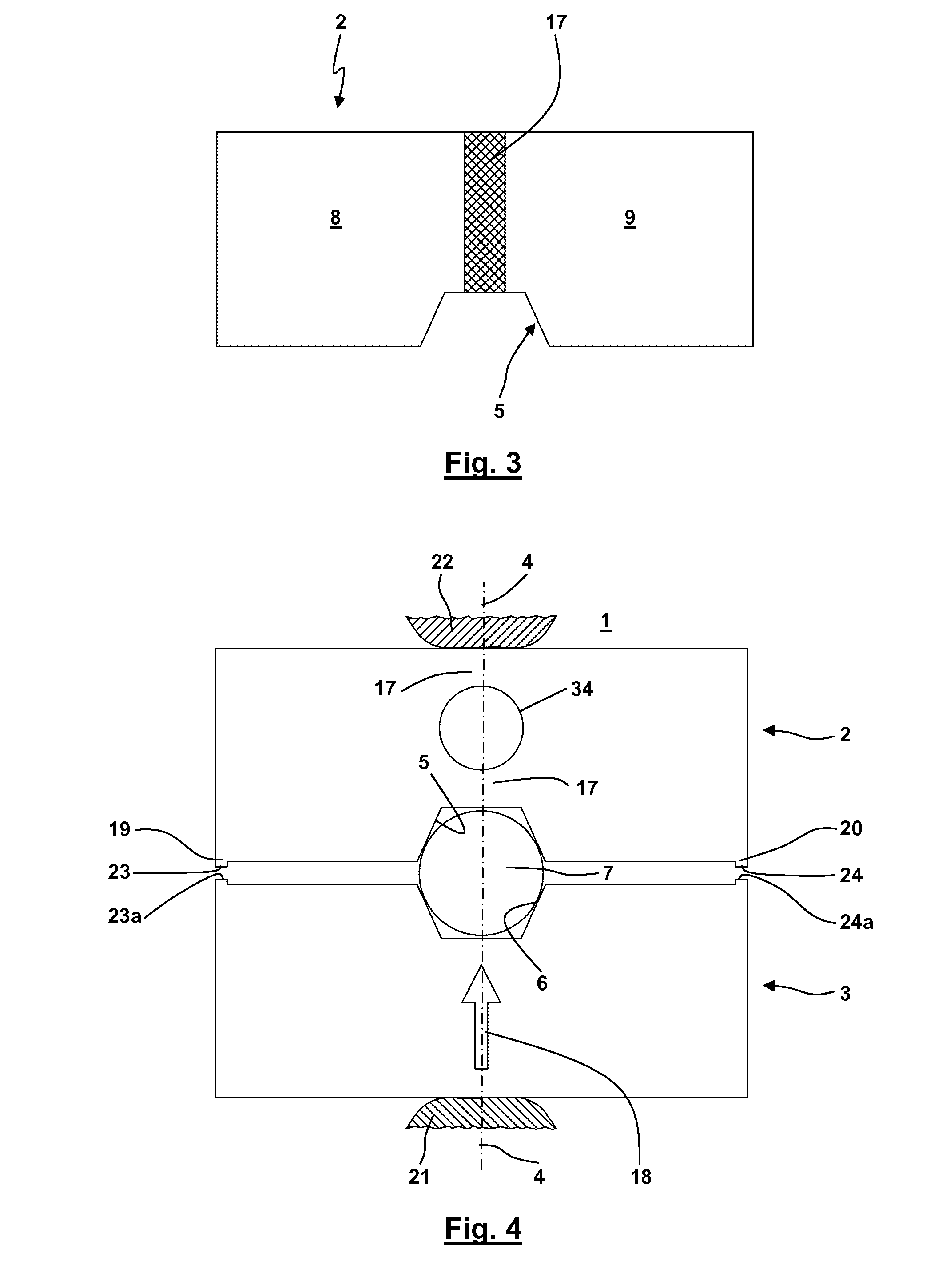

[0037]The invention relates to a crimping tool, in particular crimping pliers 1, with any drive mechanism, in particular manually activated hand levers or an electric or hydraulic drive. The crimping pliers 1 (besides the inventive features described in the following) might have any design or construction known from prior art. In particular, the crimping pliers 1 might have activation mechanisms, a force locking unit, a locator or a head of the pliers or other constructive details known from crimping pliers distributed by the present applicant, in particular known from documents U.S. Pat. No. 4,794,780, U.S. Pat. No. 5,153,984, EP 0 471 977 B1, U.S. Pat. No. 5,187,968, DE 44 27 553 C2, U.S. Pat. No. 5,913,933, DE 197 09 639 A1, DE 197 53 436 C2, U.S. Pat. No. 6,053,025, U.S. Pat. No. 6,026,671, DE 298 03 336 U1, U.S. Pat. No. 6,155,095, DE 198 34 859 C2, U.S. Pat. No. 6,286,358, U.S. Pat. No. 6,289,712, U.S. Pat. No. 6,474,130, U.S. Pat. No. 6,612,147, U.S. Pat. No. 6,877,228, DE 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic degree of freedom | aaaaa | aaaaa |

| angle of inclination | aaaaa | aaaaa |

| ejection force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com