Container cover and milk powder can

A container cover and container technology, applied to jars, non-detachable lids/covers, closures with auxiliary devices, etc., can solve the inconvenience, the easy-to-tear seal cannot be torn off, the first fastening part and the second fastening Parts are easy to detach and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment one, a kind of container lid:

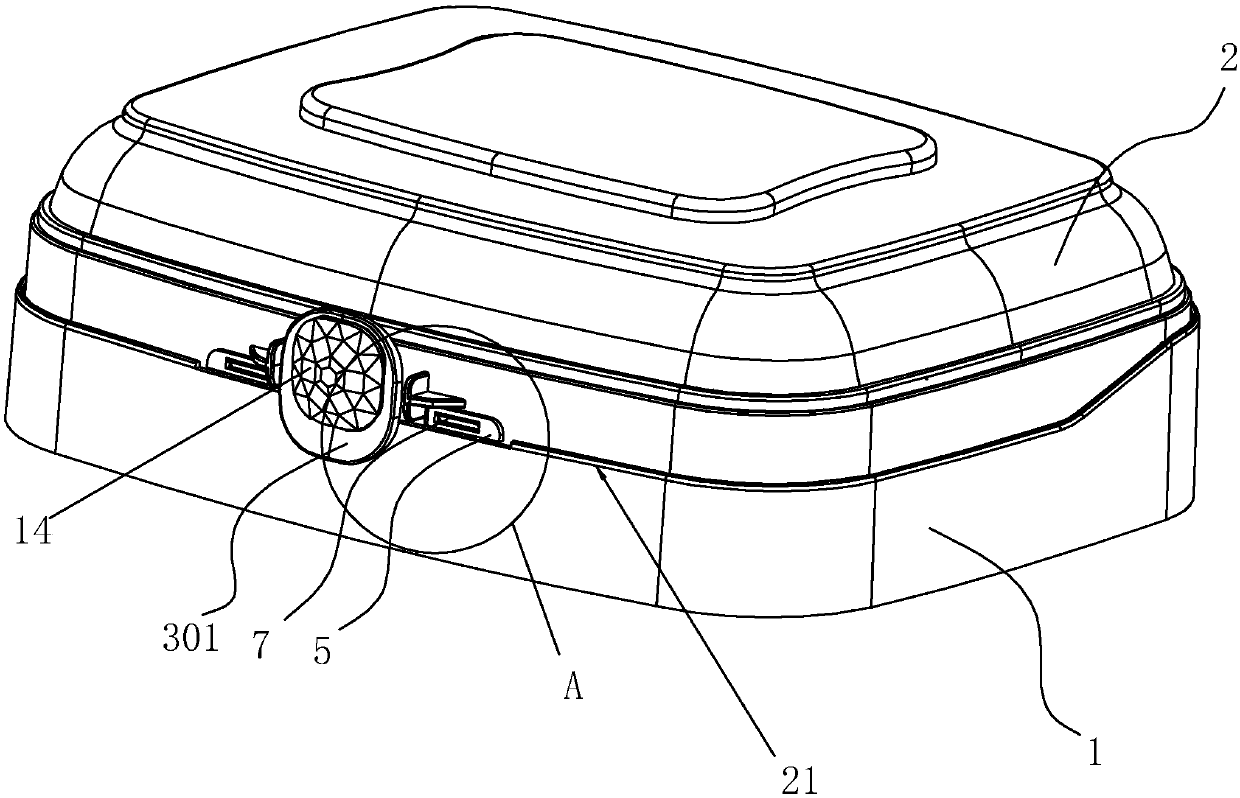

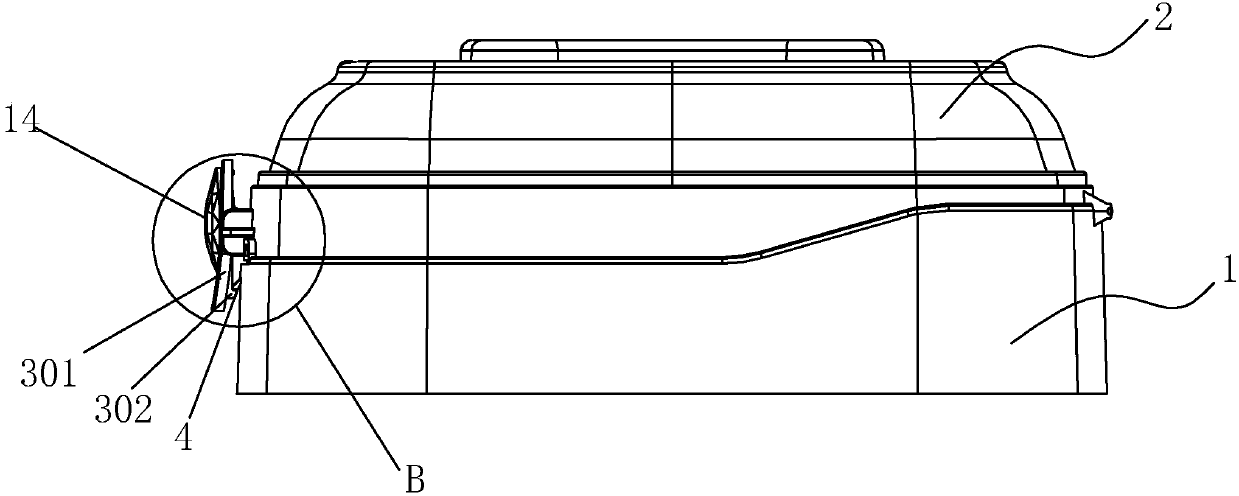

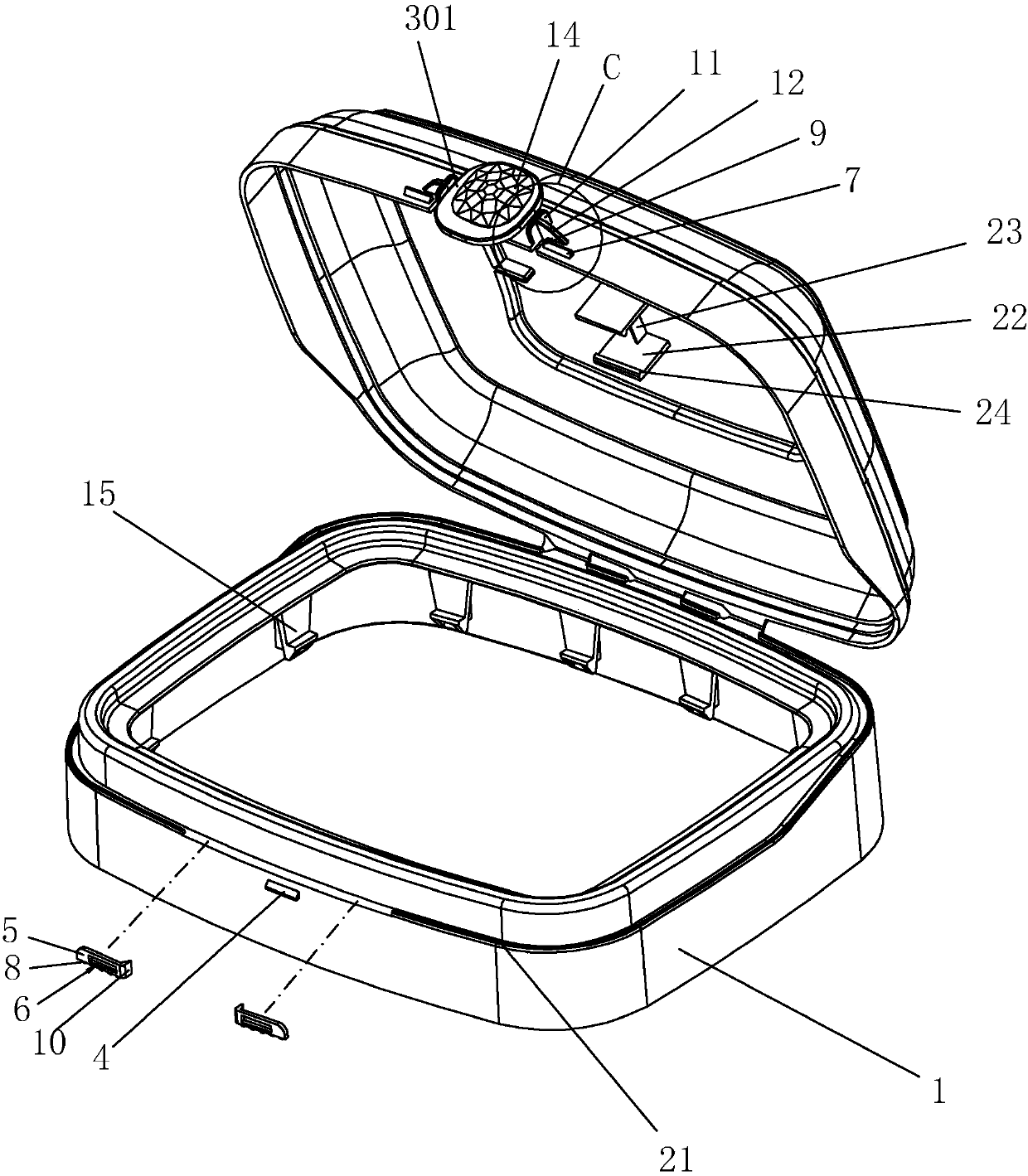

[0040] as attached figure 1 and 4 The shown container cover includes a collar 1 fastened to the upper end of the container, and a flip cover 2 arranged on the upper end of the collar 1. One side of the flip cover 2 is hinged to one side of the collar 1, and the two can be hinged by a flexible belt. It can also be hinged by a hinge shaft; the upper edge of the outer circumference of the collar 1 extends upwards with a surrounding edge 21, and the surrounding edge 21 gives way to the position of the actuator 301, and the surrounding edge 21 wraps around the outer circumference of the flip cover 2 when the flip cover 2 is fastened. outside. A first fastening piece is provided on the flip cover 2 away from its hinged end, and a second fastening piece that is fastened with the first fastening piece is provided on the collar 1; figure 2 , 5 And 7, the first fastening member includes an actuator 301, hook teeth 302, and a support...

Embodiment 2

[0043] Embodiment two, a kind of milk powder tank:

[0044] as attached Figure 8 , 9 The milk powder can shown in 10 and 10 includes a tank body 25 and a container cover in Embodiment 1. Several hooks 15 are provided on the inner ring surface of the collar 1, and the hooks 15 are in the form of barbs 24. The tank body 25 The outer edge of the top is provided with a connecting end 16 that is nested with the collar 1, wherein the connecting end 16 is provided with a slot 17 that matches the hook 15, and the slots 17 are evenly distributed on the outer circumference of the connecting end 16. , the container cover is fastened to the opening on the tank body 25 through the collar 1, where the cooperation between the draw groove 17 and the hook 15 ensures the stability of the connection between the container cover and the tank body 25.

[0045] Simultaneously, because more milk powder is housed in the milk powder tank, it is heavier, and it is not easy to grab the milk powder tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com