High-efficiency disassembling tool for inner ring of bearing

A technology for bearing inner rings and disassembly tooling, which is applied in the direction of manufacturing tools and hand-held tools, etc., can solve the problems of large axial size of disassembly tooling, low disassembly efficiency, and high manufacturing cost, and achieves simple structure, low processing cost, and guaranteed structure The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

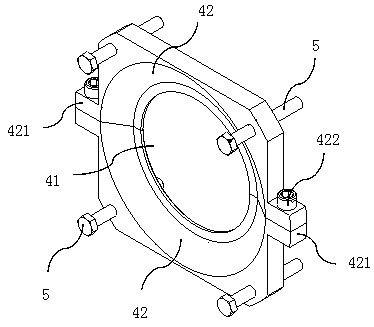

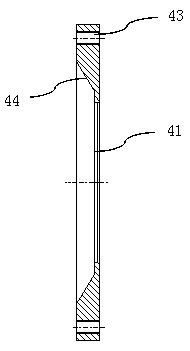

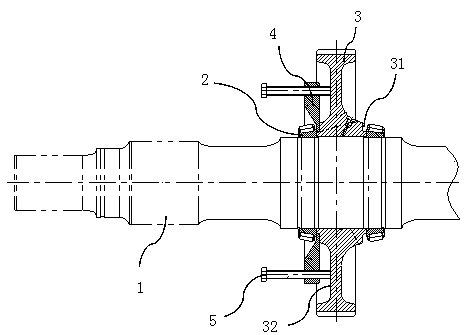

[0022] Such as figure 1 with image 3 As shown, an efficient disassembly tool for bearing inner ring is provided, which is applied to the disassembly of the bearing on the shaft, and is especially suitable for the dismantling of the bearing inner ring 2 on the axle 1 in the rail transit car material gear box. The axle 1 is installed close to the bearing. There is a gear 3, and the disassembly tool includes a closed disassembly ring 4 with an inner hole 41 formed by connecting two sub-disassembly rings 42 with the same structure in sequence. The gear 3 is provided with a circumferential groove 31 for closing the disassembly ring at the installation and joint of the bearing 2 4 The embedded and embedded closed and disassembled ring 4 The first end face is attached to the end face of the bearing inner ring 2 and the second end face is attached to the side wall of the upper circumferential groove 31 of the gear. The inner hole wall of the closed and disassembled ring 4 is attached t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com