Directly compressible composition comprising microcrystalline cellulose

a technology of microcrystalline cellulose and composition, applied in the direction of pill delivery, etc., can solve the problems of unsatisfactory hardness of tablets which cannot be handled in pharmaceutical practice, inconvenient and expensive granulation steps, and the need to remove solvents necessary for wet granulation with high energy input, etc., to achieve low ejection force, low friabilities, and high tablet hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0091]The present description enables the person skilled in the art to apply the invention comprehensively. Even without further comments, it is therefore assumed that a person skilled in the art will be able to utilise the above description in the broadest scope.

[0092]If anything is unclear, it goes without saying that the publications and patent literature cited should be consulted. Accordingly, these documents are regarded as part of the disclosure content of the present description.

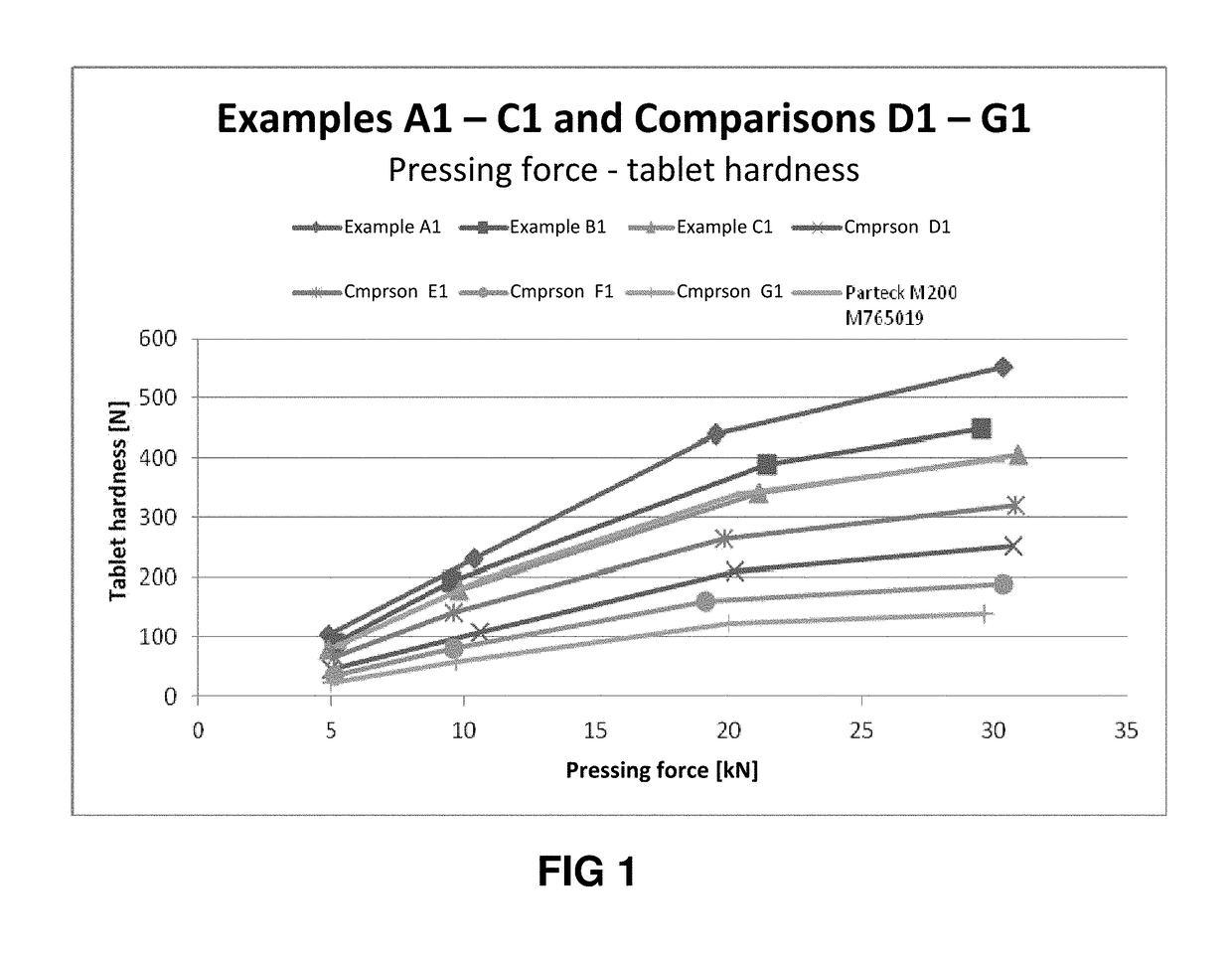

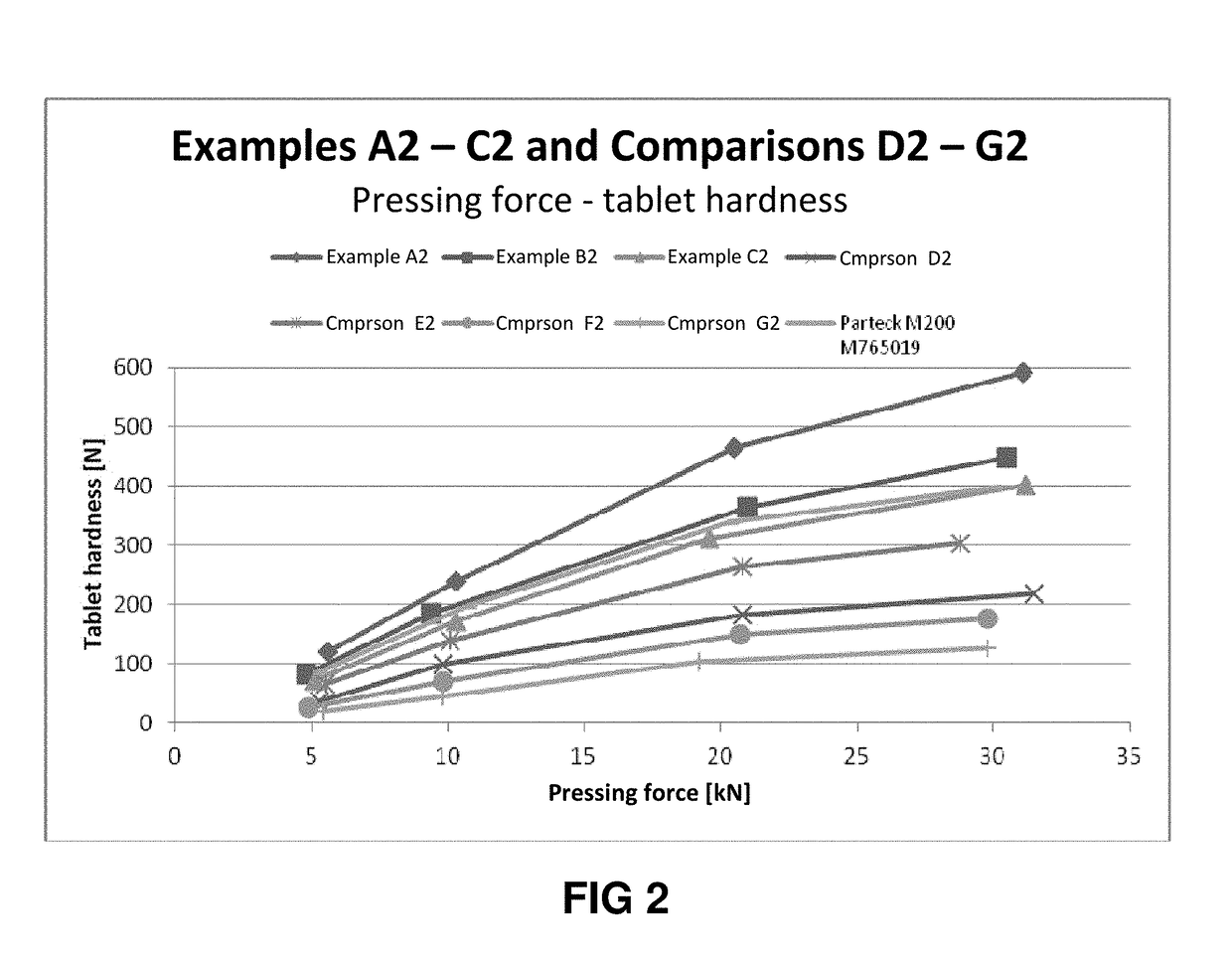

[0093]For better understanding of the invention and in order to illustrate it, examples are given below which are within the scope of protection of the present invention. These examples also serve to illustrate possible variants. Owing to the general validity of the inventive principle described, however, the examples are not suitable for reducing the scope of protection of the present application to these alone.

[0094]Furthermore, it goes without saying to the person skilled in the art that, both in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle sizes | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| pressing force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com