Process and apparatus for producing a tabletting aid and also a tabletting aid and tabletting mixture

An adjuvant and tableting technology, which is used in non-active ingredients in medical preparations, pill delivery, pharmaceutical formulations, etc. It can solve the problems of excessive mixing, low tablet hardness and tablet coverage, and save production time. and cost, low ejection force, high production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

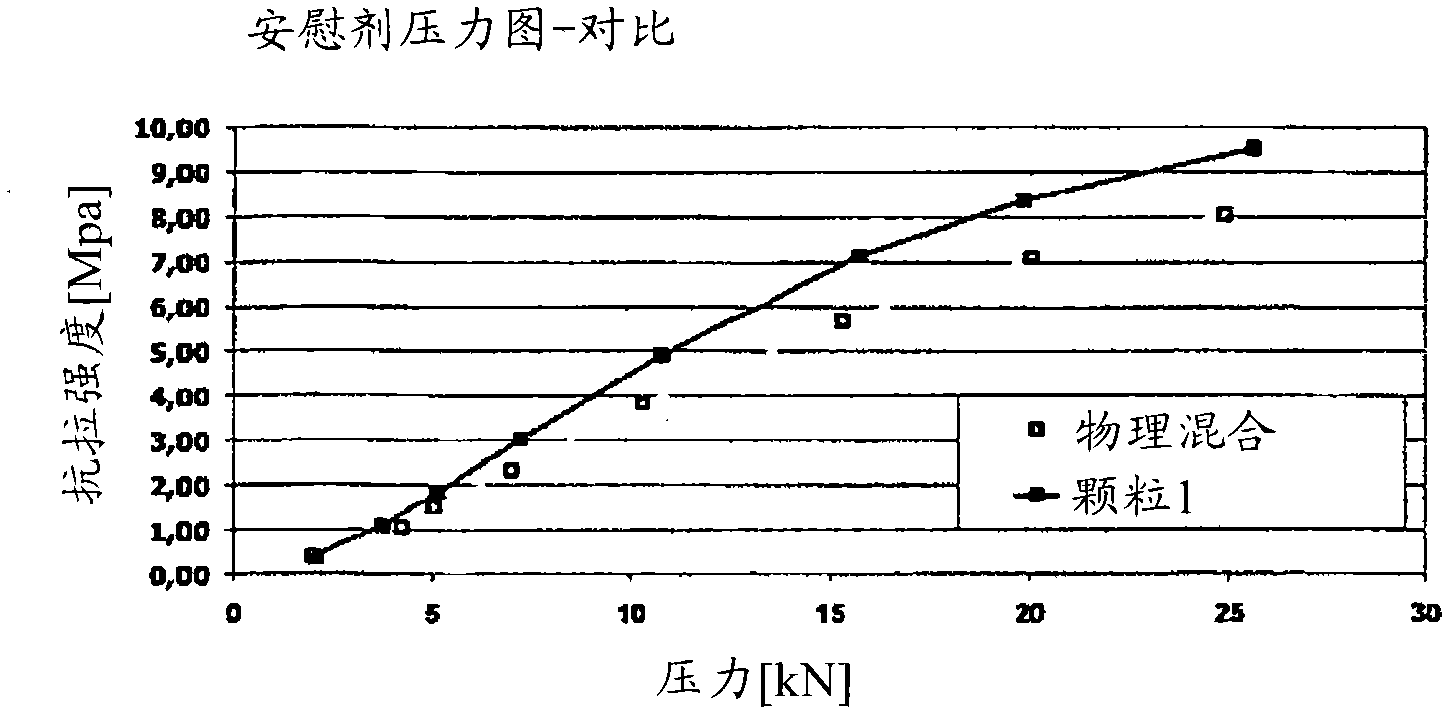

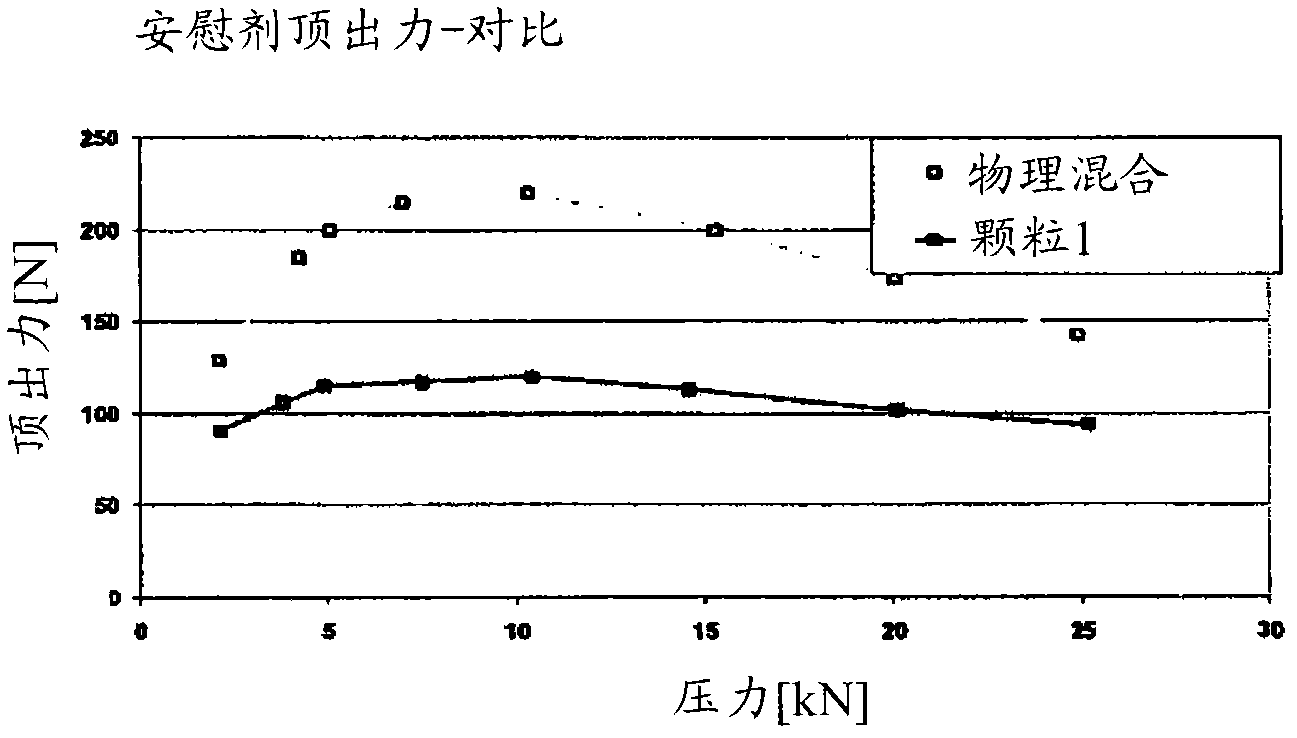

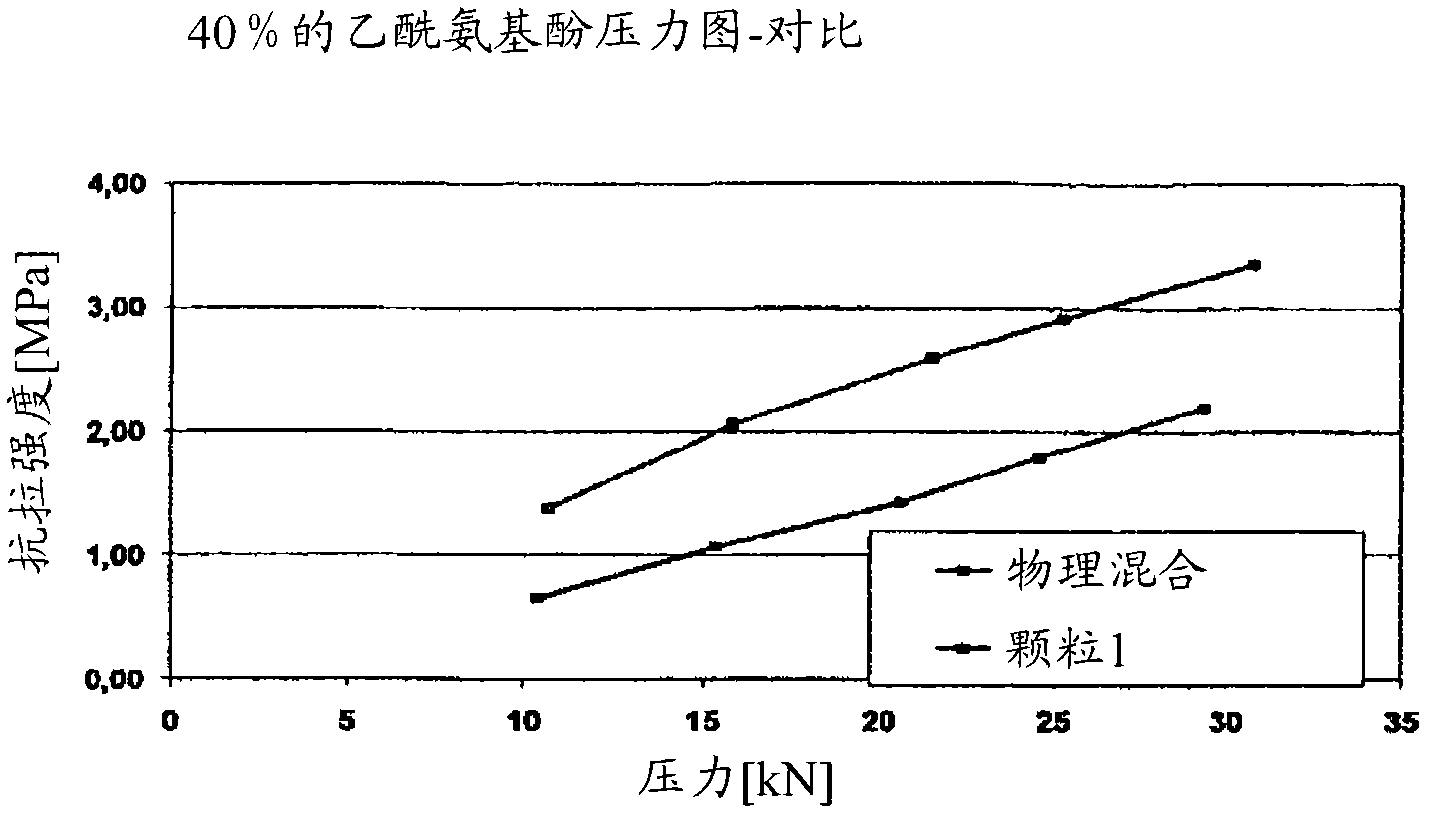

[0044] Tableting aids according to the invention were compared in a placebo (Placebo), 40% acetaminophen (Paracetamol) and enalapril (Enalapril) with a list of physical mixtures consisting of the individual components. The results are given in Tables 2, 3 and 4.

[0045] ·Placebo tablets

[0046]

[0047] ★ Tableting aids according to the invention are only compressed at different pressures.

[0048] ★★ All components except PRUV were mixed for 15 minutes. Lubricant was then added, mixed for an additional 3 minutes and compacted at various pressures.

[0049] Table 2: Direct comparison between tableting aid (granulate 1) and physical mixture consisting of a single component;

[0051]

[0052] The DC-tabletting aids according to the invention show significantly better compressibility and tablet hardness, lower ejection forces and less abrasion than physical blends (Table 2, figure 1 and 2 ).

[0053] Acetaminophen (Paracetamol) tablets

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com