Intelligent container for automatically storing and picking up cargoes one to one

An automatic, container-based technology, applied in storage devices, transportation and packaging, etc., can solve problems such as inability to guarantee the control of incoming and outgoing goods, inability to meet one-to-one automatic storage and retrieval of goods, and increased management costs, etc., to achieve a simple structure , smooth movement and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

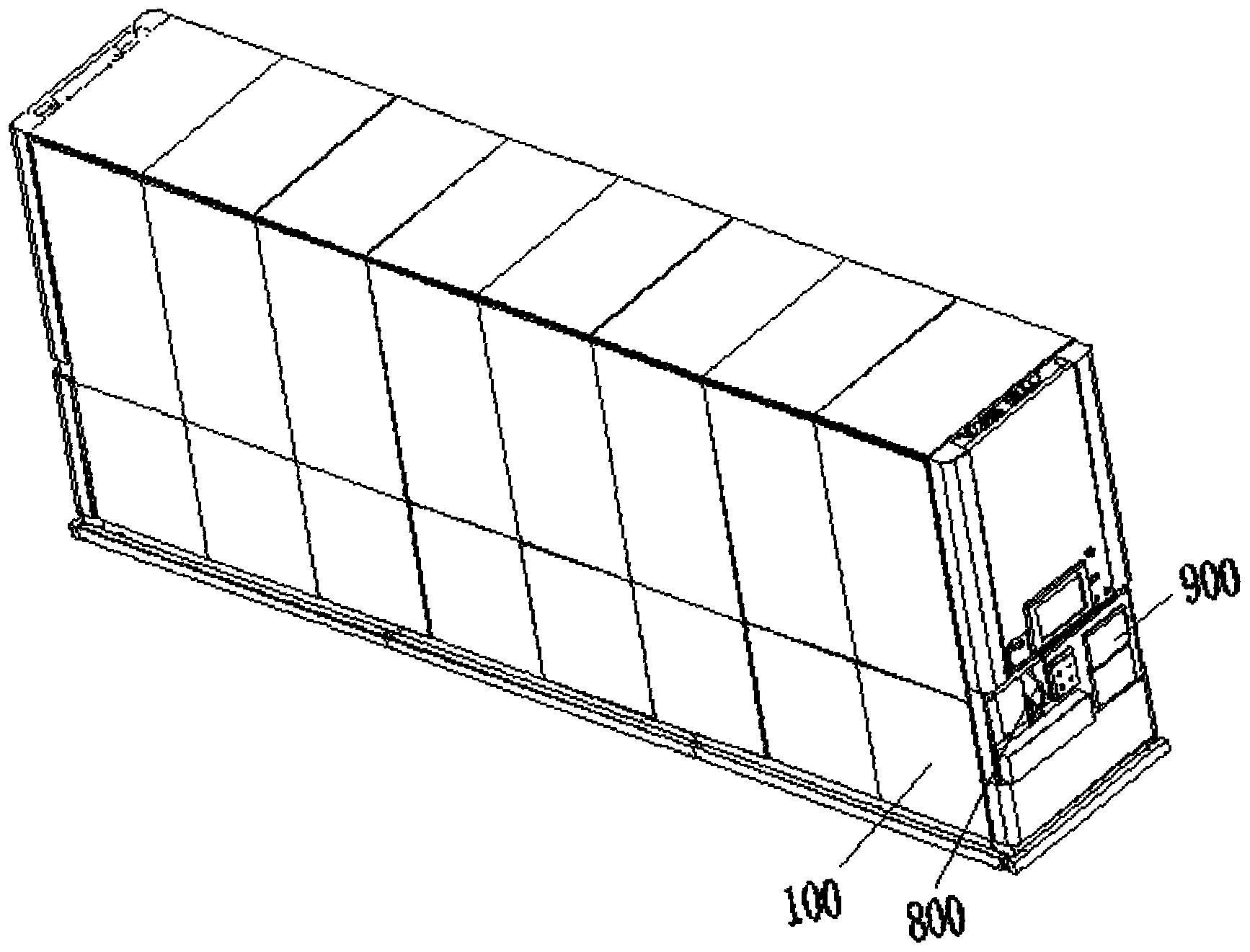

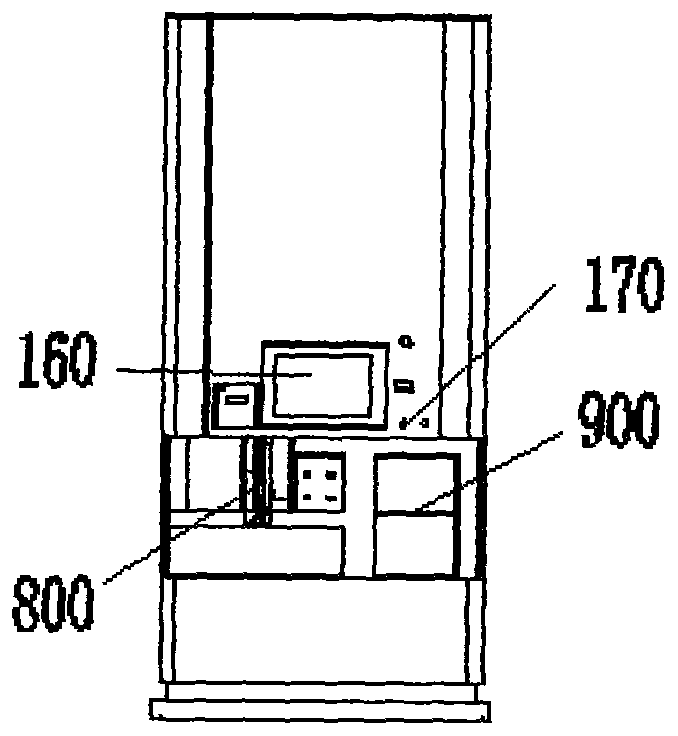

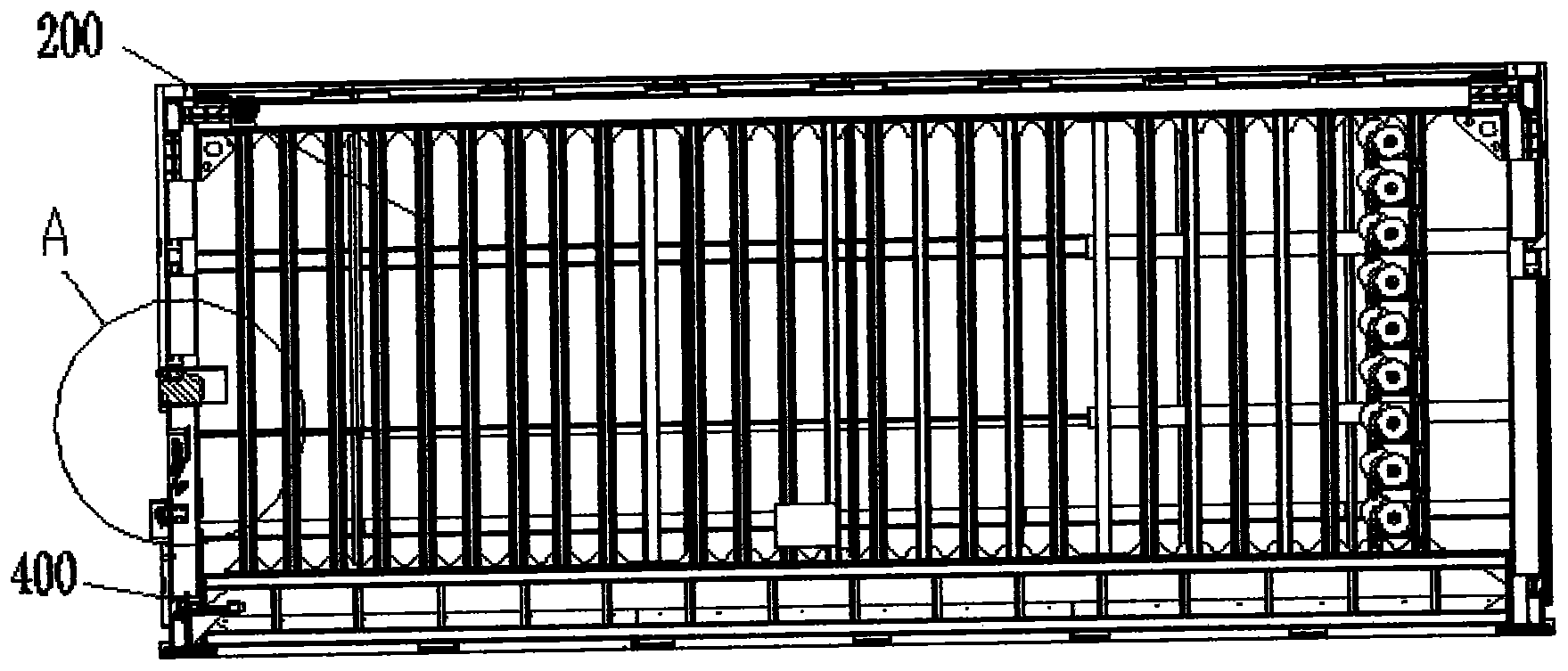

[0037] Such as Figure 1-7 As shown, it is a structural schematic diagram of a one-to-one automatic storage and retrieval of goods of the present invention. It can be seen from the figure that it includes: a cabinet 100, a fork mechanism 700 arranged in the cabinet 100, and a The cargo box structure on the inner cantilever shelf and the smart car 500, wherein the cargo box structure includes a rotating cargo box 600 and / or a common cargo box, the common cargo box is a drawer, and the drawer type cargo box in the prior art can be used Structure; the rotating cargo box includes: a bottom plate; a cargo box arranged on the upper surface of the bottom plate; a connecting device for connecting the bottom plate and the cargo box, and the cargo box includes a plurality of magazines arranged side by side, each The silo can rotate relative to the bottom plate; a thimble mechanism 400 with a thimble 44 is provided in the cabinet 100 near the cargo opening; wherein, the cabinet 100 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com