Transfer making machine

A technology of fonts and bottom plates, applied in decorative art, engraving, etc., can solve the problems of impossible engraving, labor and time-consuming, and difficult to guarantee positioning accuracy, etc., and achieve the effect of high engraving efficiency, wide practical range, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

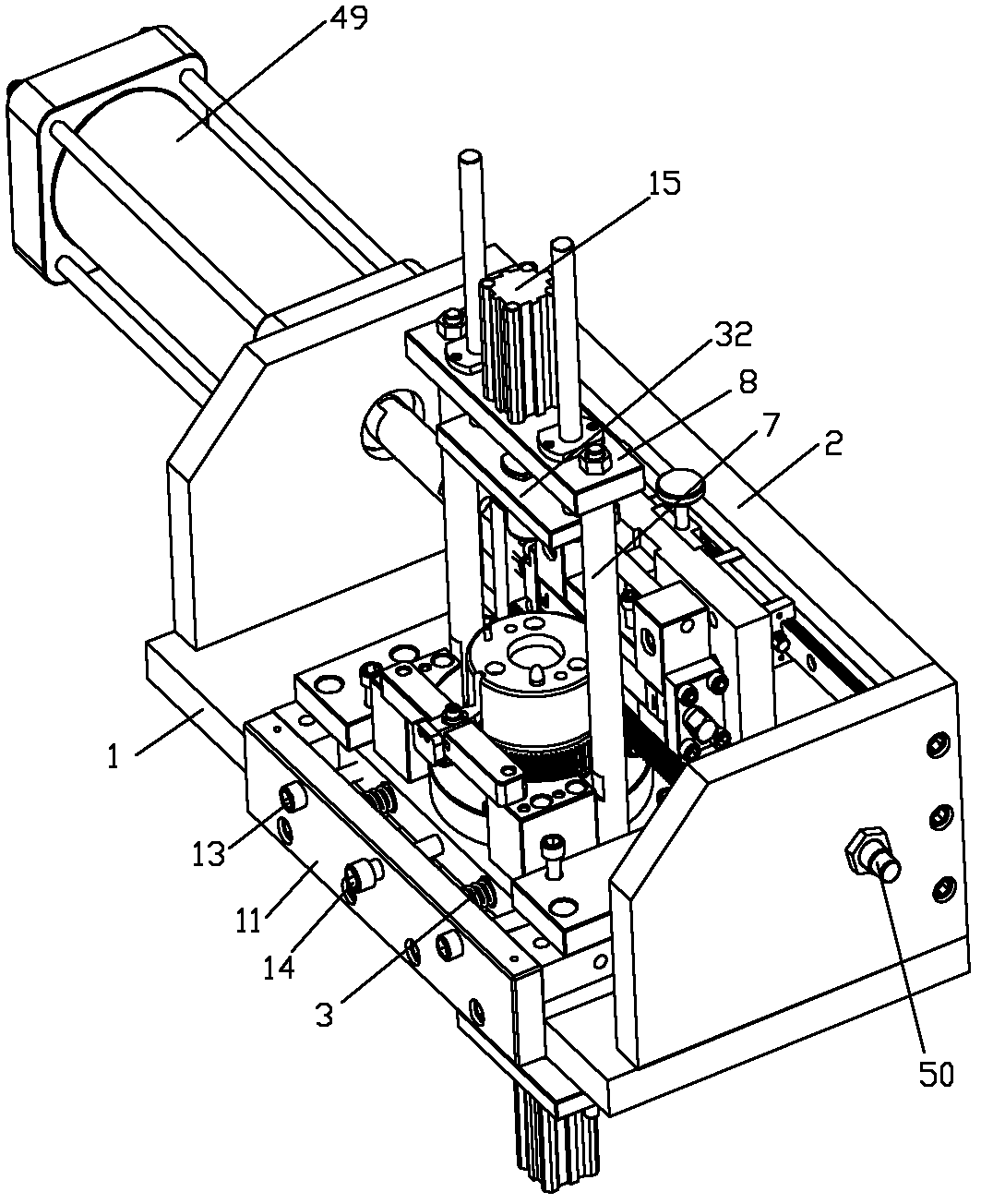

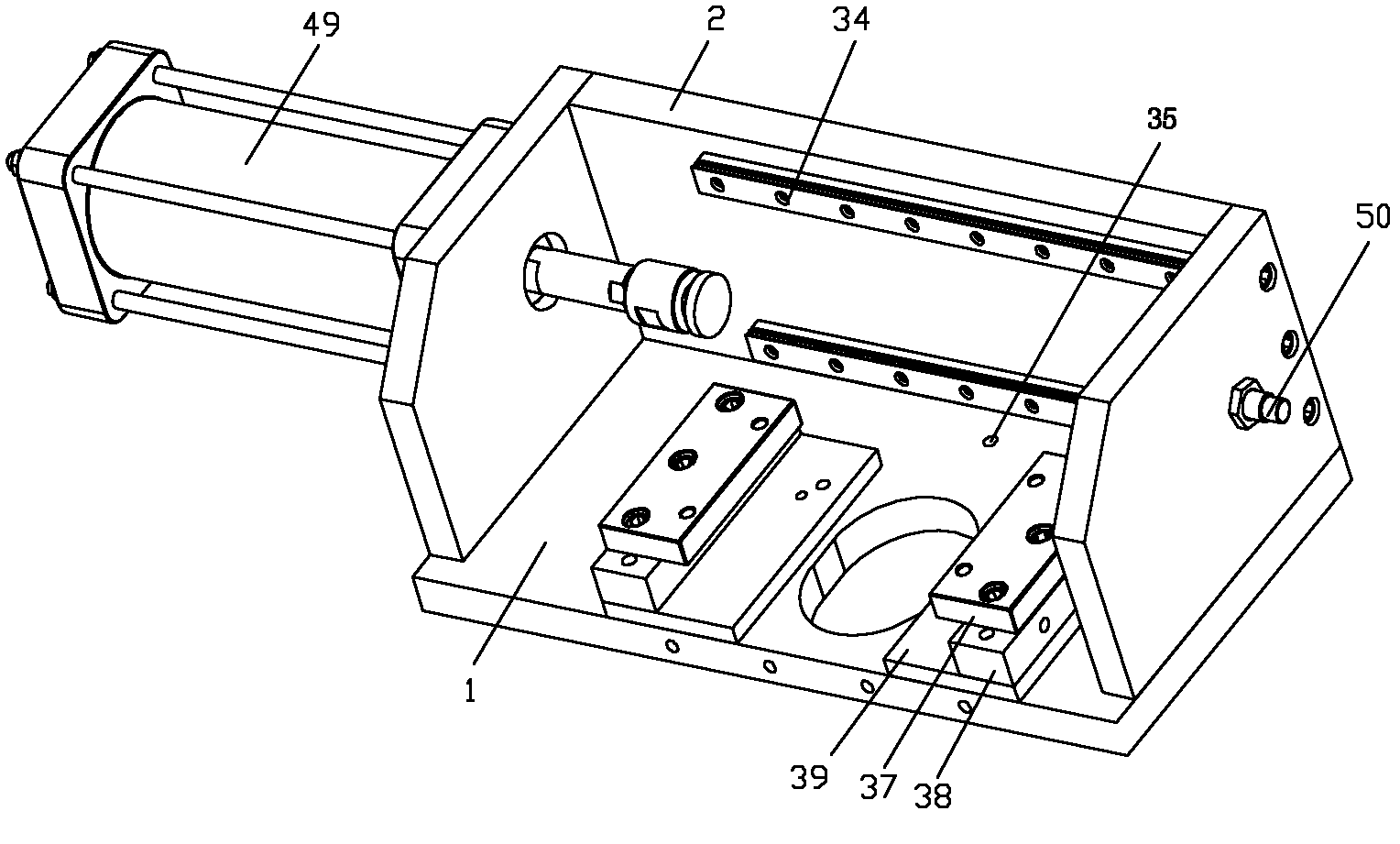

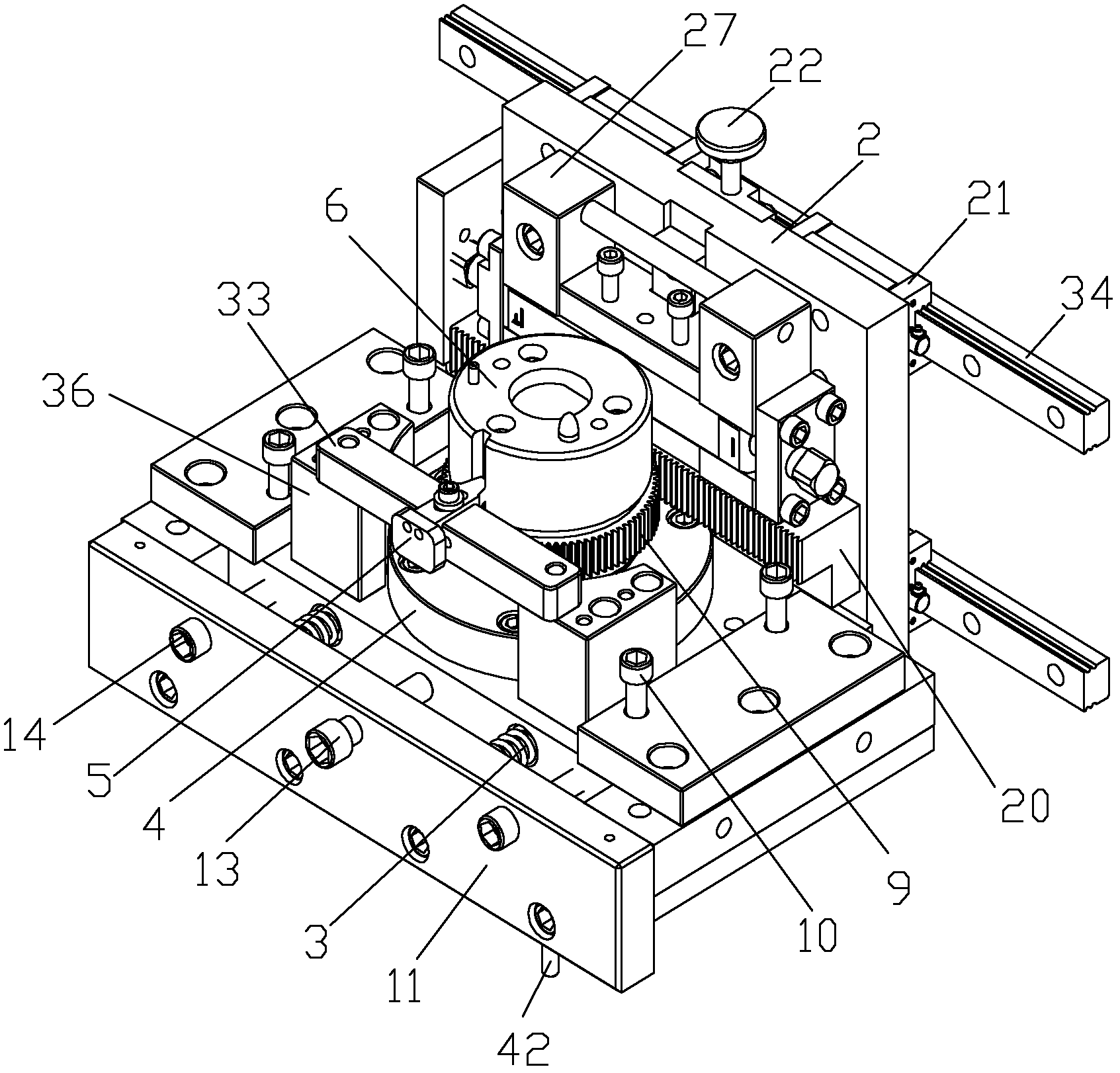

[0025] refer to Figure 1 to Figure 3 , the transformation machine of the present invention uses compressed air as the power to rotate the cylindrical workpiece, and while the cylindrical workpiece is rotating, the pre-made characters are distributed along the circumference of the workpiece and engraved on the outer surface of the cylindrical workpiece, so it is called "Zhuan". machine. The specific structure of the transformation machine of the present invention is as follows:

[0026] The bottom plate 1 is provided with a support plate 2, and the side wall of the support plate is slidably fitted with a skateboard assembly that can move along the left and right directions of the bottom plate. The transmission rack 20 is located below the type support device. The base plate is provided with a bearing seat 4, and the base plate 1 is provided with a through hole for the bearing seat 4 to pass through. The mandrel 40 is arranged in the bearing housing 4 , a transmission gear 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com