Laser half-cutting machine for crystal silicon solar battery cell

A technology of solar cells and laser cutting, which is applied in the direction of laser welding equipment, circuits, electrical components, etc., can solve the problems affecting the appearance of cell components, photoelectric conversion efficiency, damage, and low processing efficiency of cells, and achieves strong practicability , easy to use and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

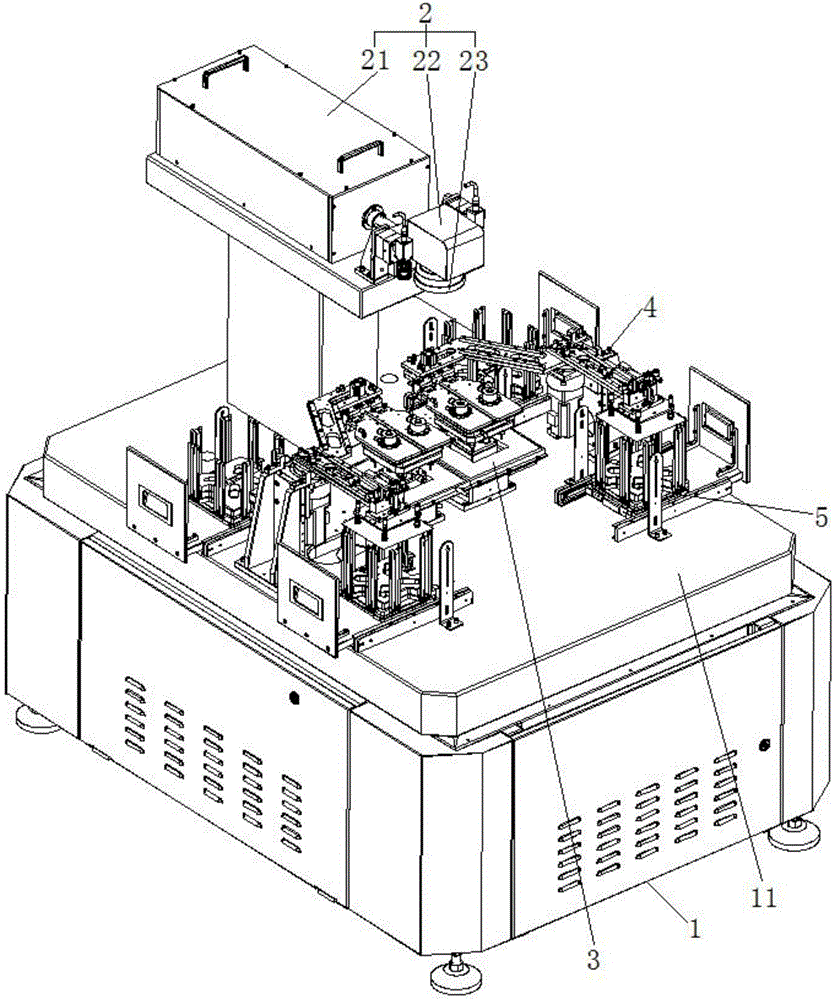

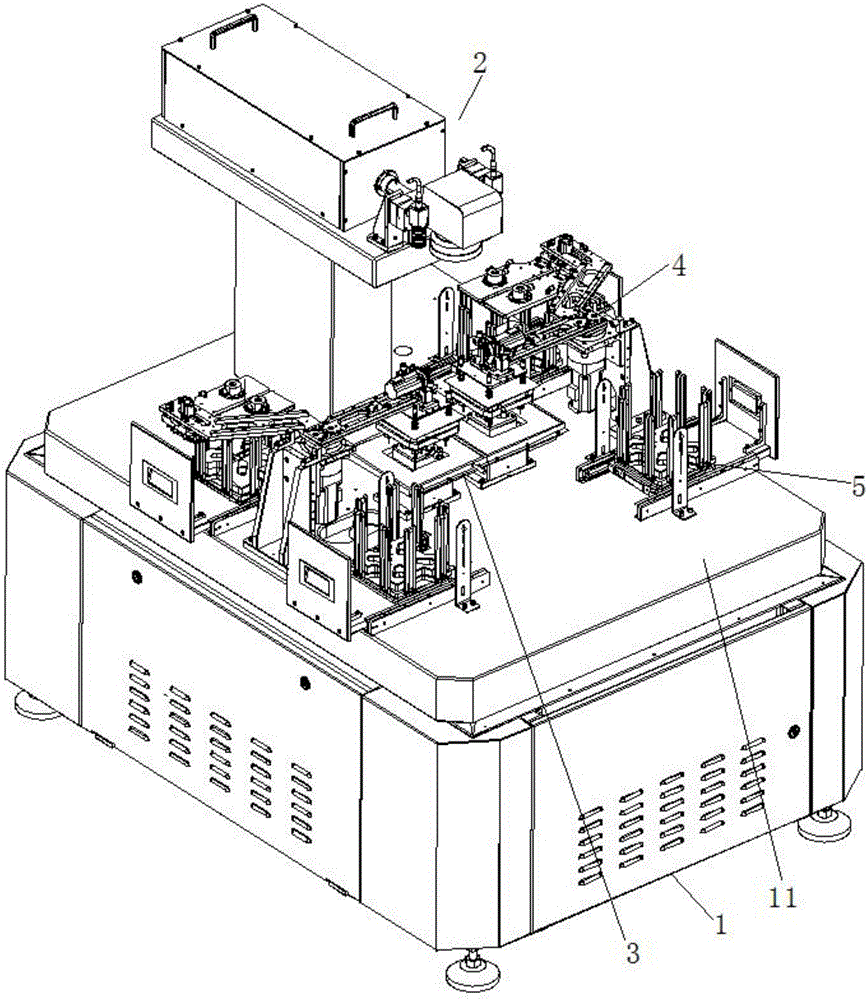

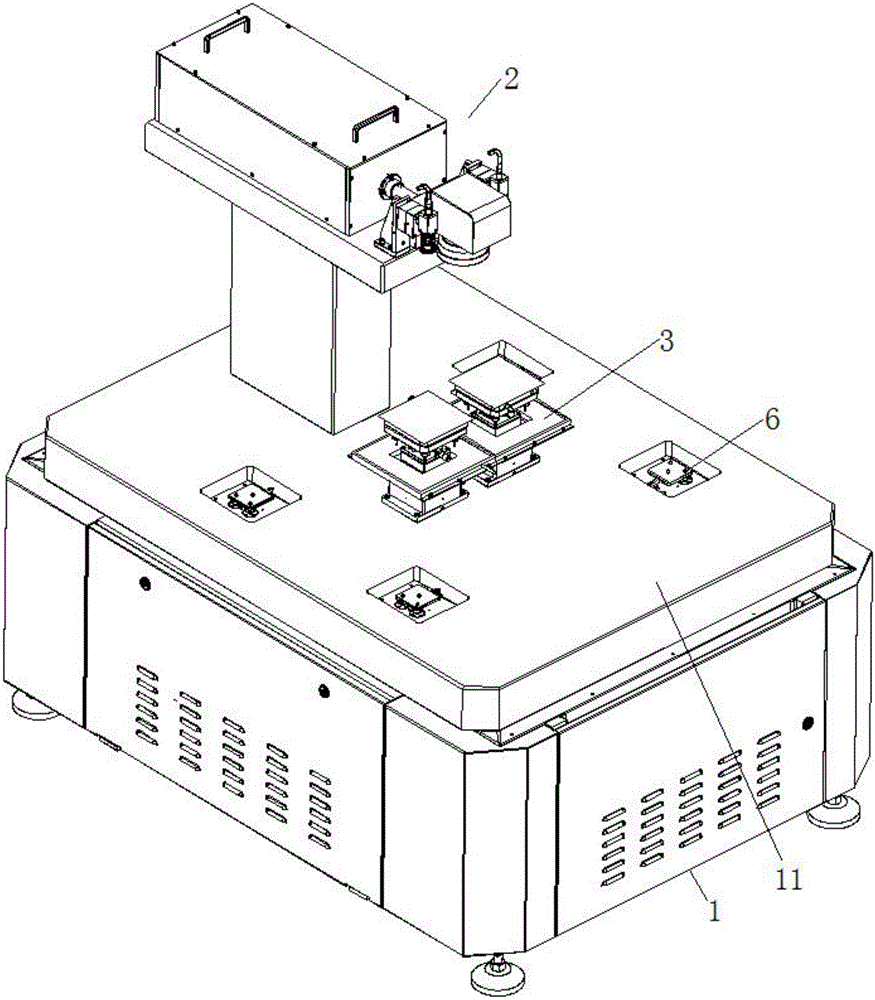

[0040] Example: such as Figures 1 to 4 As shown, the crystalline silicon solar cell laser cutting machine in this embodiment includes a chassis 1, a laser scanning system 2, two processing tables 3 and two rotary transfer devices 4;

[0041] The top of the cabinet 1 has a worktable 11, and the above-mentioned laser scanning system 2 is installed on the above-mentioned worktable 11;

[0042] The two above-mentioned processing tables 3 are installed side by side and at intervals on the above-mentioned worktable 11, and the laser processing head of the above-mentioned laser scanning system 2 is located directly above the middle position between the two above-mentioned processing tables 3;

[0043] The two above-mentioned rotary transfer devices 4 are installed on the worktable 11 respectively, and are arranged on the corresponding side of the above-mentioned processing table 3 in one-to-one correspondence;

[0044] The above-mentioned rotary transfer device 4 includes a rotary dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com