Discharging system of full-automatic mould pressing moulding equipment

A fully automatic and blanking technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of low production efficiency, high labor intensity, poor consistency, etc., and achieve the effect of improving production efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] to combine Figure 7 to Figure 10 As shown, the blanking system of a kind of automatic mold pressing and setting equipment of the present embodiment includes a frame 1, a lower mold circulation conveying mechanism 4 installed on the frame, and the lower mold circulation conveying mechanism is loaded with a lower mold 42; The frame is located above the lower mold circulation conveying mechanism and is equipped with a blanking mechanism 6 for conveying raw materials from the lower mold circulation conveying mechanism to the finished product storage mechanism 7; the lower mold circulation conveying mechanism and the blanking mechanism The mechanism is respectively connected with the control system; the unloading mechanism includes a material transfer cylinder b61 horizontally installed on the frame, a material transfer plate b62 connected with the piston rod of the material transfer cylinder b, and a material transfer plate b62 vertically installed on the material transfer ...

Embodiment 2

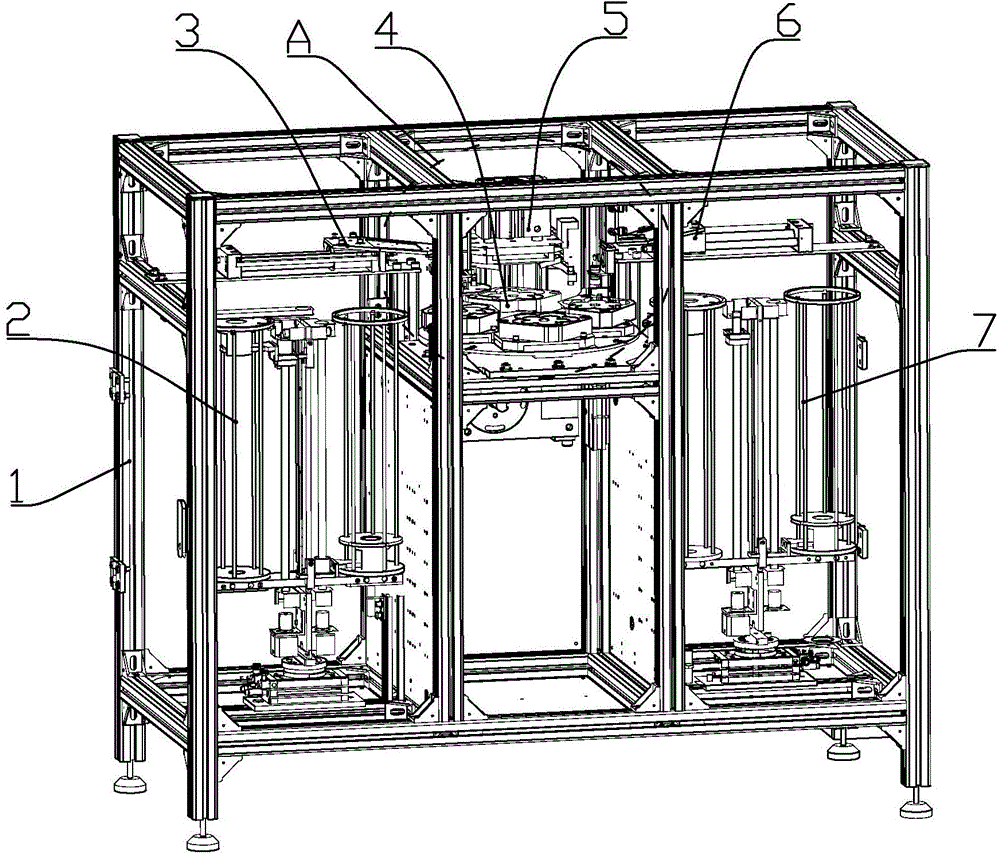

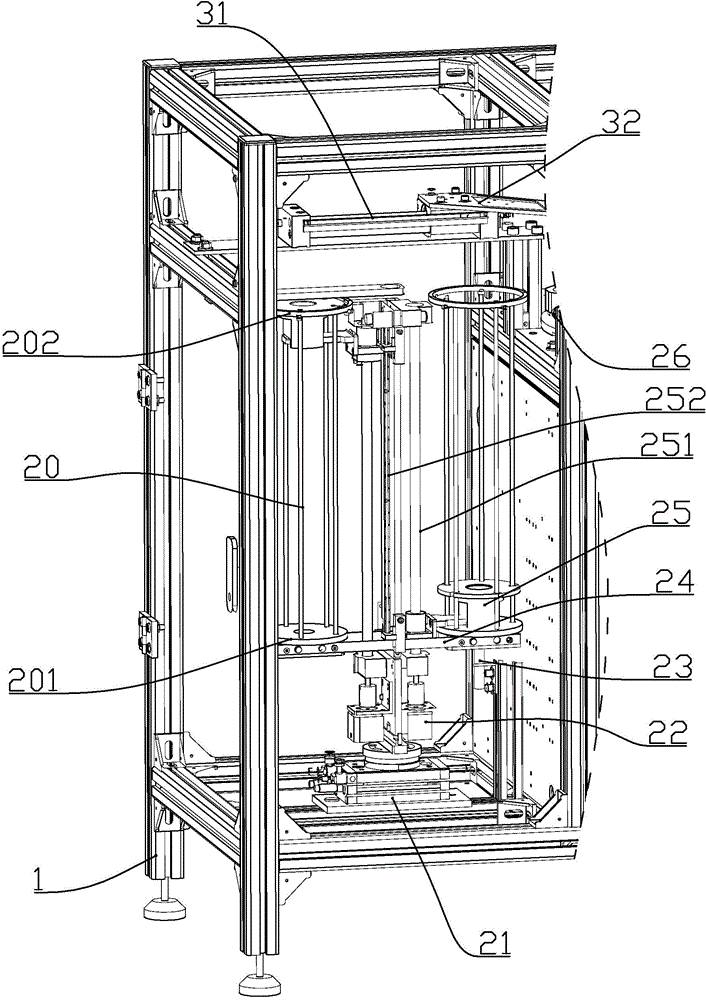

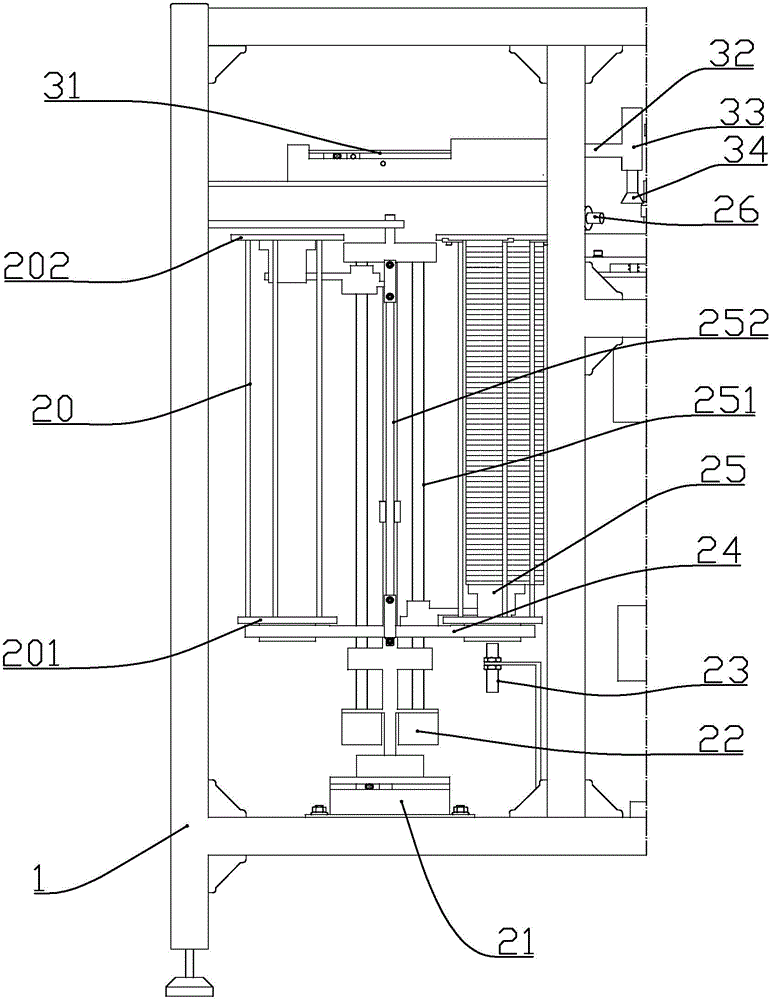

[0035] according to Figure 1 to Figure 9 As shown, a kind of fully automatic molding and shaping equipment described in this embodiment includes a frame 1, a feeding mechanism 2 installed on the frame, a lower mold circulation conveying mechanism 4 and a finished product storage mechanism 7. At least three lower molds 42 are loaded on the mold circulation conveying mechanism; a feeding mechanism 3 is installed on the frame above the feeding mechanism and the lower mold circulating conveying mechanism to transport raw materials from the feeding mechanism to the lower mold; On the frame, a molding mechanism 5 is installed above the lower mold, and an upper mold 52 that cooperates with the lower mold is loaded below the molding mechanism; Raw materials are transported from the lower mold circulation conveying mechanism to the unloading mechanism 6 on the finished product storage mechanism; Control system connection.

[0036] to combine figure 2 , image 3 As shown, the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com