Space assembly type tooth-type joint structure

A tooth-shaped node and assembled technology, which is applied in the direction of building structure and construction, can solve the problems of difficult construction quality assurance and high construction cost, and achieve the effects of fast construction speed, reduced construction difficulty and cost, and improved rotational rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

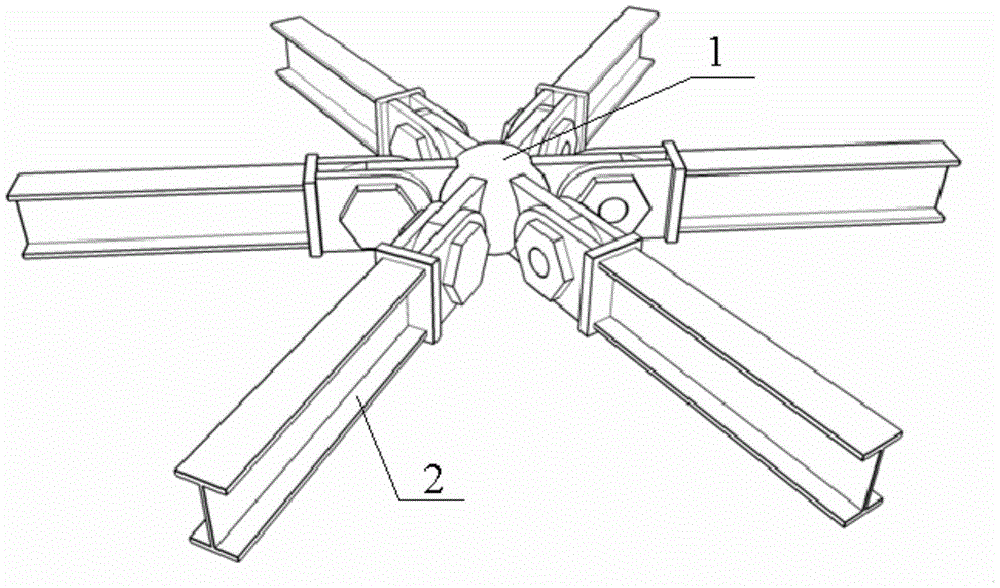

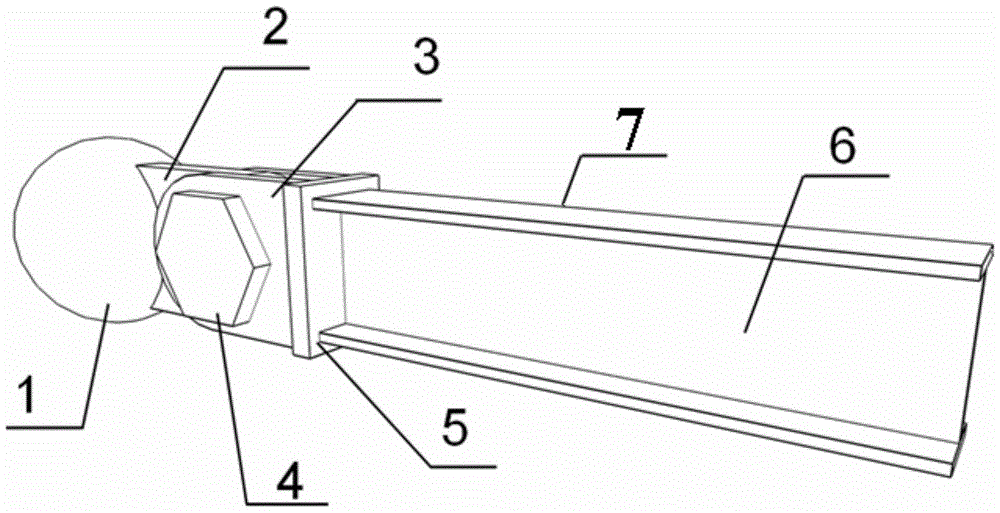

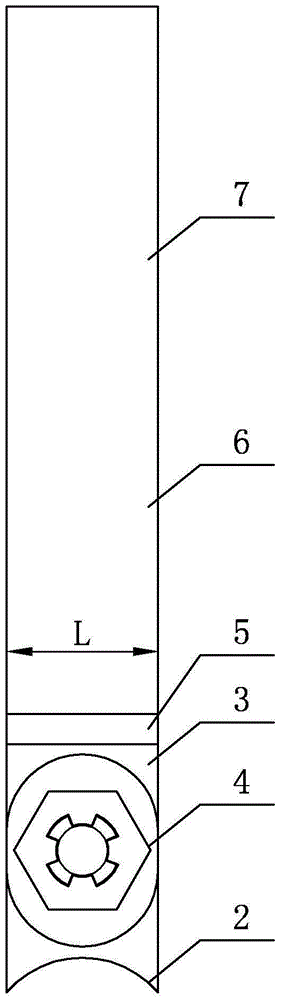

[0008] Specific implementation mode one: combine Figure 1-Figure 8 Describe this embodiment. The space-assembled tooth-shaped node structure described in this embodiment includes a hollow ball 1 and N connecting assemblies 7, and each connecting assembly 7 includes an intermediate ear plate 2, a toothed bolt 4, and a connecting rod end plate 5. The connecting rod 6, the nut 8 and the two ear plates connect the side plates 3; the two ear plates connecting the side plates 3 are fixed side by side on one end surface of the connecting rod end plate 5, and one end of the connecting rod 6 is fixedly installed on the connecting rod On the other end face of the end plate 5, one end of the middle ear plate 2 is arranged between the two ear plate connection side plates 3, and the middle ear plate 2 and the two ear plate connection side plates 3 are connected by toothed bolts 4, nuts 8 threads are installed on the toothed bolt 4, N connecting components 7 are arranged horizontally, and ...

specific Embodiment approach 2

[0009] Specific embodiment two: combine Figure 1-Figure 4 This embodiment is described. In the space-assembled tooth-shaped node structure described in this embodiment, the thickness of the middle ear plate 2 and the distance between two side-by-side lug plates connecting side plates 3 are equal, and the others are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific embodiment three: combine Figure 1-Figure 6 Describe this embodiment, the space-assembled tooth-shaped node structure described in this embodiment, the screw of the tooth-type bolt 4 is uniformly processed with a plurality of tooth-shaped protrusions 4-1 along the circumferential direction, and enhances tensile and compressive strength Performance, others are the same as the specific embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com