Spiral-unearthing pipe-jacking pipe curtain construction method and device

A construction method and construction equipment technology, applied in the field of spiral excavation pipe jacking pipe curtain construction and equipment, can solve the problems of low construction precision, large ground disturbance, high construction cost, etc., and achieve high construction precision, low construction cost, and no mud pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

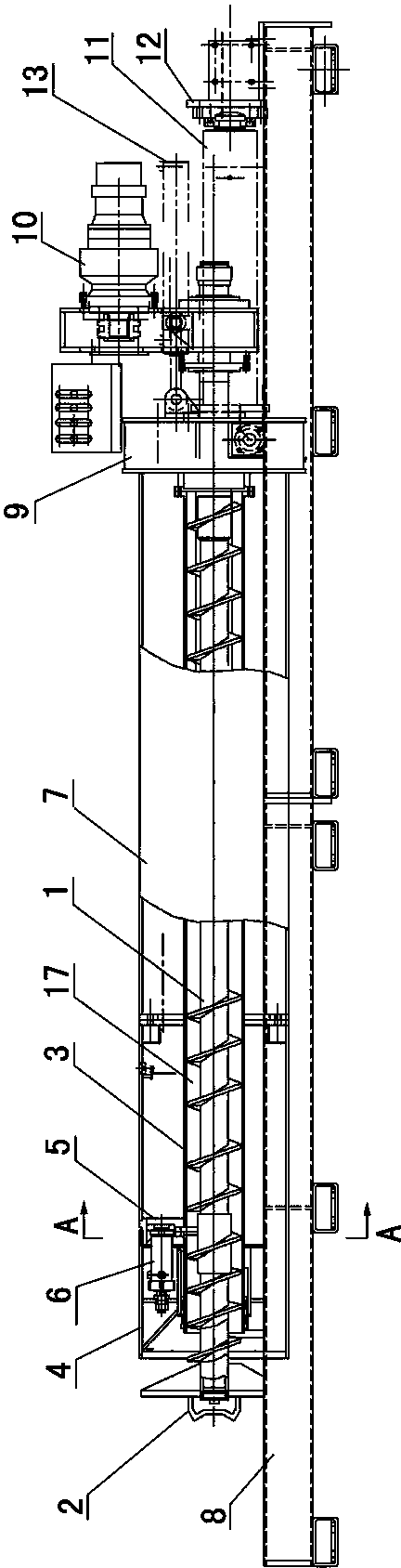

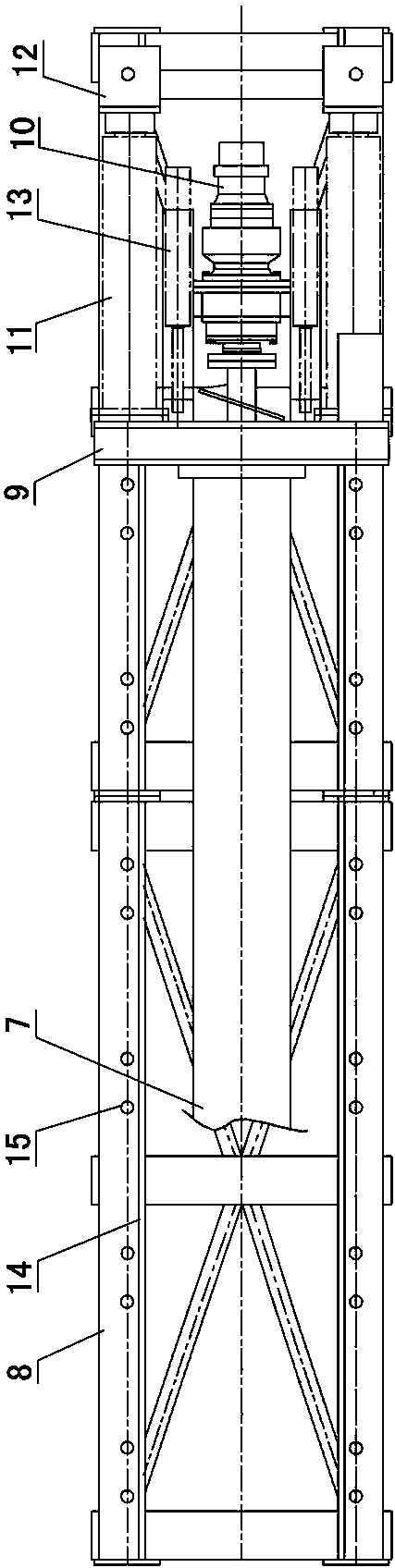

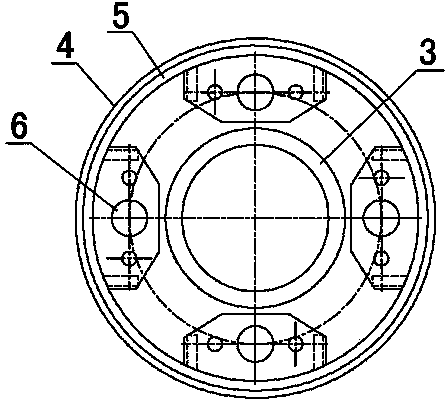

[0029] Examples see Figure 1-5 As shown, the first spiral excavation pipe jacking pipe curtain construction method is aimed at the pipe curtain with a specification of Φ400mm~Φ800mm, and the construction steps are as follows.

[0030] Step 1. Foundation pit and site preparation, that is, setting up the jacking pit and receiving pit. Specifically, the jacking foundation pit meets the requirements of pipe curtain construction and steel pipe hoisting, and concrete is poured at the bottom of the jacking foundation pit at the frame foot position and the rear top back position to harden the site. Clean up the site, and set up crane positions, stacking positions for auger drill pipes and casings, stacking positions for pipe curtain steel pipes, drilling rig pump stations, and electric welding machines at the end of the jacking pit as required.

[0031] Step 2. Install and debug the spiral excavation pipe jacking pipe curtain construction equipment and electric welding machine. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com