Box shaped house model of construction and fabricating method

A house model and box-type technology, which is applied in the direction of building construction, construction, and on-site preparation of building components. It can solve the problems that hinder the modernization of the construction industry, the quality of use is not ideal, and the cost of machinery is high, so as to shorten the processing and production time. , reduce the cost of machinery costs and construction costs, and reduce the effect of transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

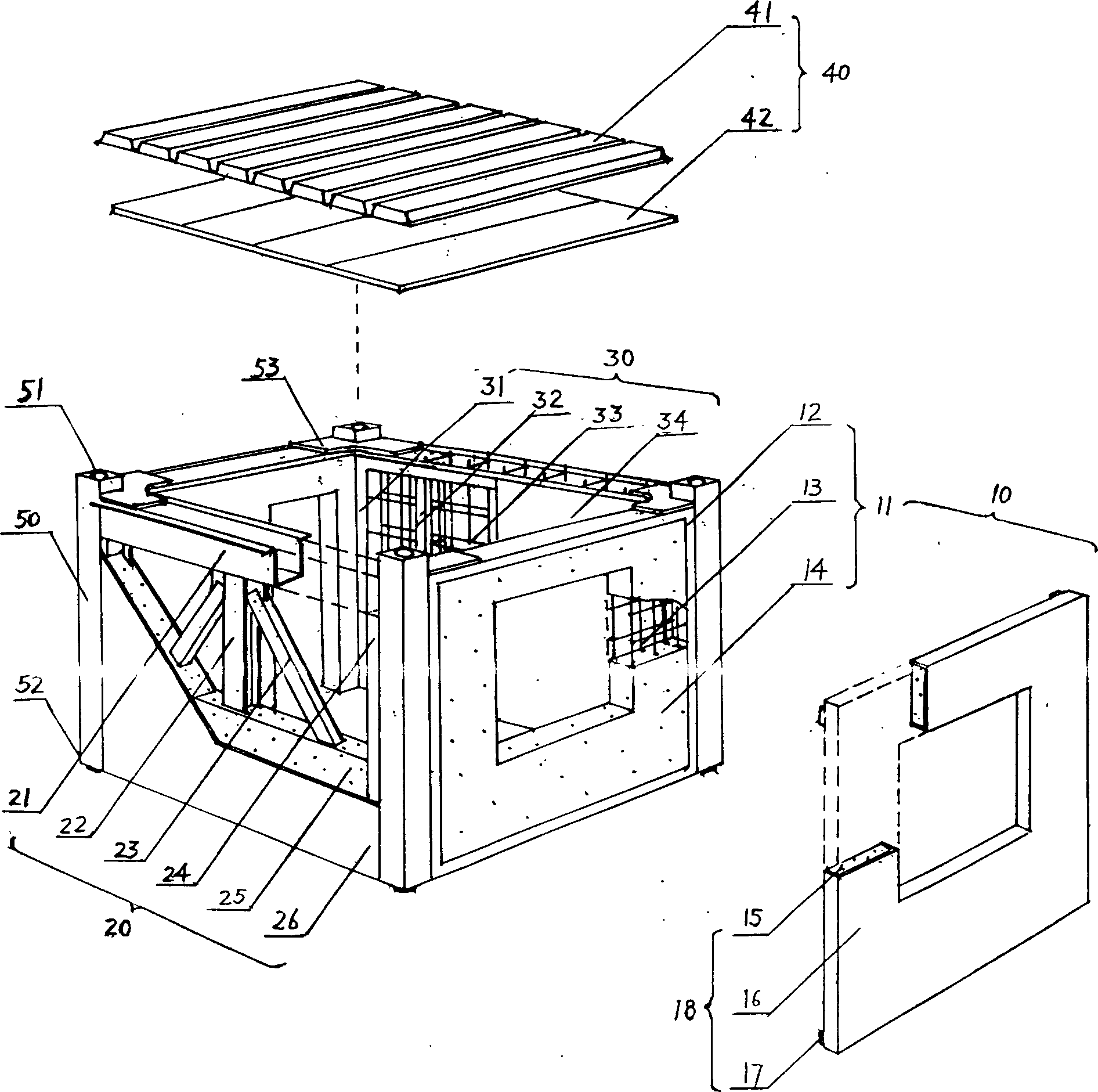

[0051] Such as figure 1 As shown, the box-type building house formwork of the present invention, it is made up of composite exterior wall panel 10, interior wall panel 20 or 30, roof formwork 40 and steel pipe column 50: described composite exterior wall panel 10 is made up of structural wall panel 11 and external thermal insulation Decorative panel 18 forms, and its external shape all is rectangular and has door and window hole. The width and height of the structural wall panel 11 are respectively equal to the designed indoor clear width and clear height. The steel frame 12 is welded with channel steel, the steel grid frame 13 is placed in the steel frame and welded together with the inner side of the steel frame, and the aerated concrete structure wall panel 14 is made by pouring slurry into the frame and curing. The external thermal insulation panel is fixedly connected with the structural wall, and the back is provided with a special pendant 17 for connecting and fixing w...

Embodiment 2

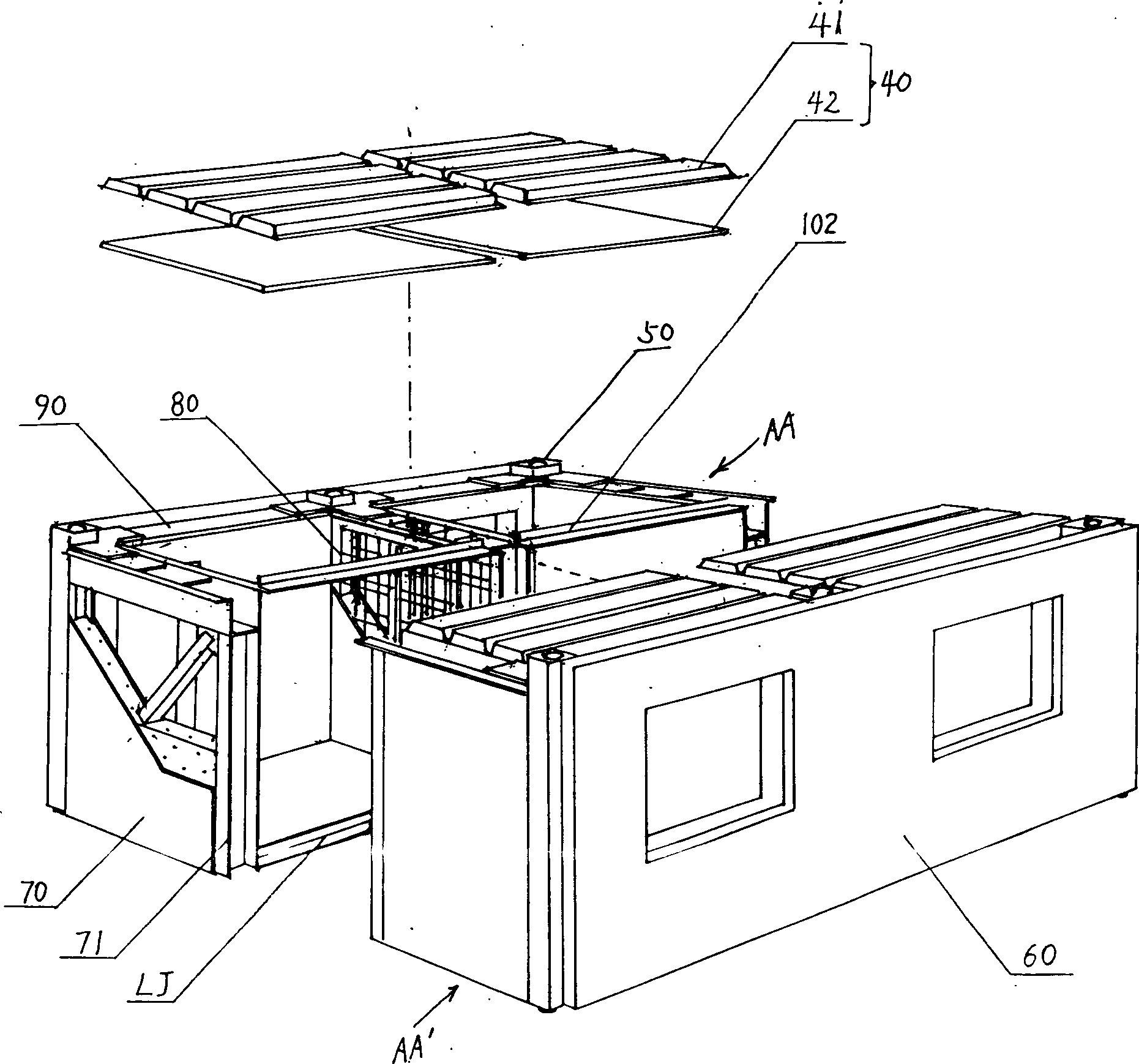

[0059] Such as figure 2 , Figure 3a , Figure 3b As shown, when a complete single box building model is not allowed to be wide enough due to the restrictions of traffic and transport vehicles, it is assembled by the method of lateral division of the double model, which is characterized in that it consists of two pieces The external wall panels 60 or internal wall panels 90 connected as one, three internal wall panels 70 and 80 each with a 1 / 2 longitudinal length, two roof formworks 90 each with an area of 1 / 2, and three steel pipe columns 50 are welded together. Methods Assemble into an open conjoined half-width house model AA or AA' that is 1 / 2 deep but connected into one. The butt joint surface of the wall panels of this conjoined half-width house formwork is channel steel 71, which forms a closed steel pipe column after welding, while the joint surface of the top plate is welded with angle steel concealed beams 102, and after pouring concrete on site, steel pipe concr...

Embodiment 3

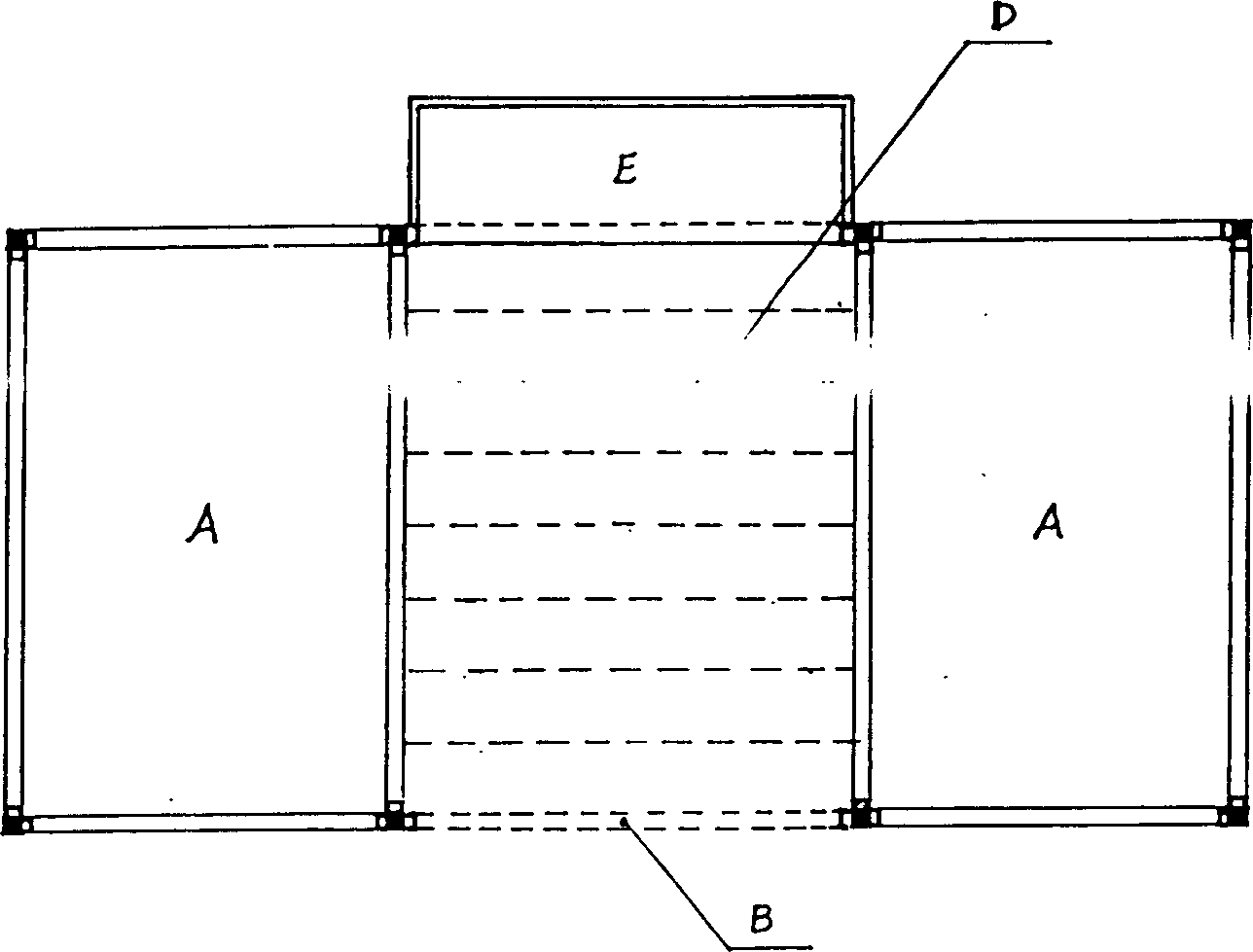

[0061] The connection and assembly methods of the box-type building model at the construction site, such as Figure 3a , Figure 3b As shown in , when the number of rooms in the same row is odd or needs to be set in a separate hall, then as Figure 3a As shown, it is assembled by the box-to-board connection method. The installation is to set up two single box-type house forms A and A separately, and connect the middle with an independent wall formwork B and an independent roof formwork D to form a new room in the middle. The method can not only avoid the overlapping of adjacent walls, reduce the unit cost, but also create a large open room. When the number of rooms in the same row is an even number or due to the restrictions of traffic and transport vehicles, the room model is not allowed to be wide enough, then if Figure 3b As shown, the conjoined half-width house models are used for docking. The method is to arrange the two conjoined half-width house models AA and AA' clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com