Static sunken pile construction technique for alternatively, sectionally and gradually spirally leading hole and statically sinking pile in pipe

A technology of internal screw and static pile driver, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of frictional resistance loss around piles, reduce the bearing capacity of PHC pipe piles, and long construction period, etc., to achieve Simple control, good construction environment and continuous construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

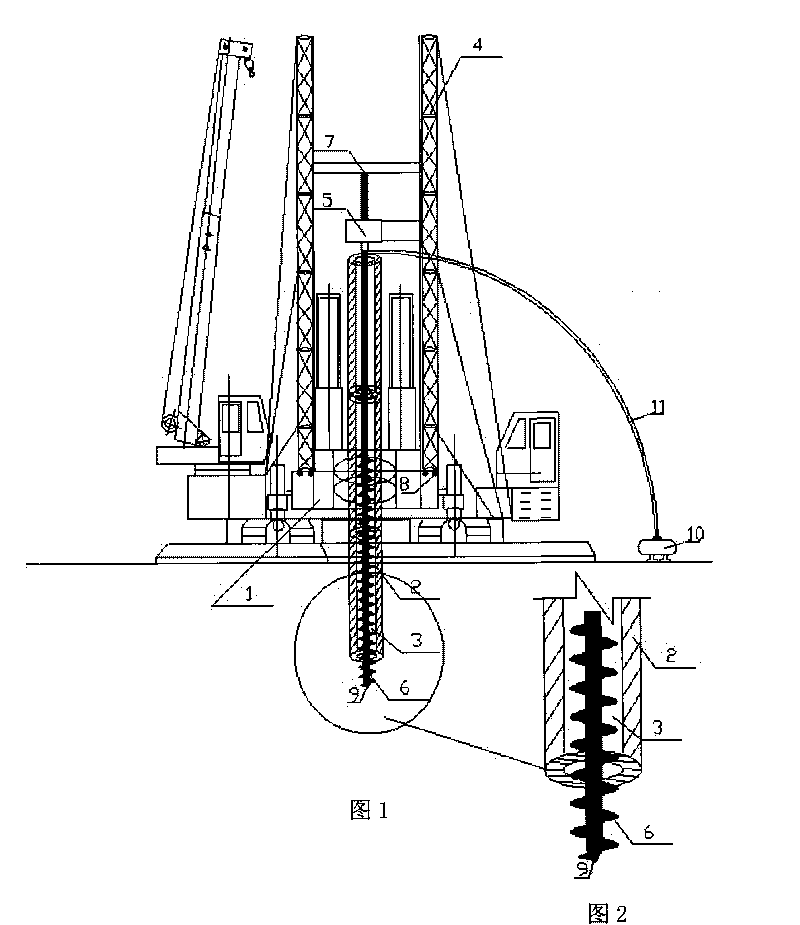

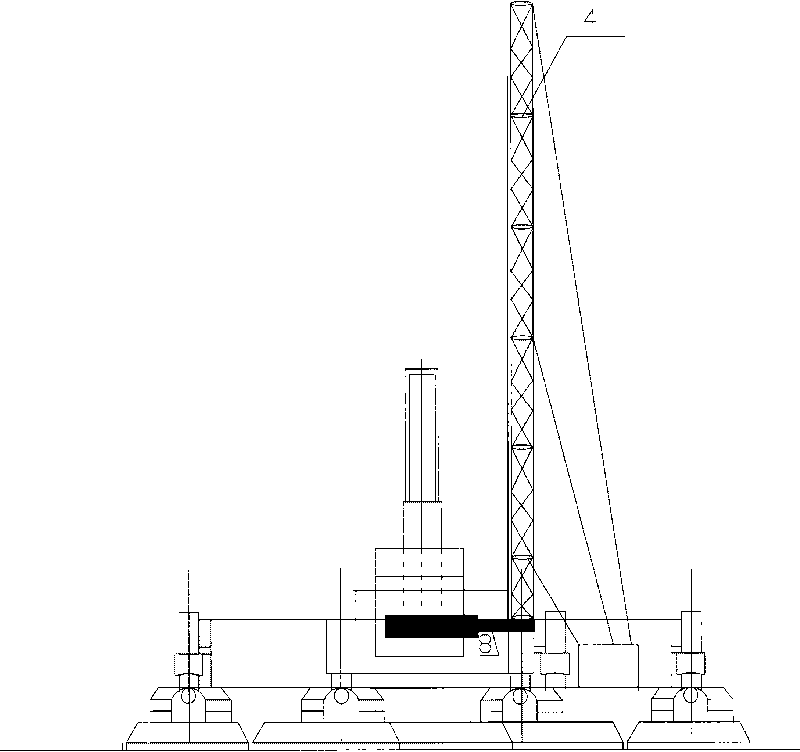

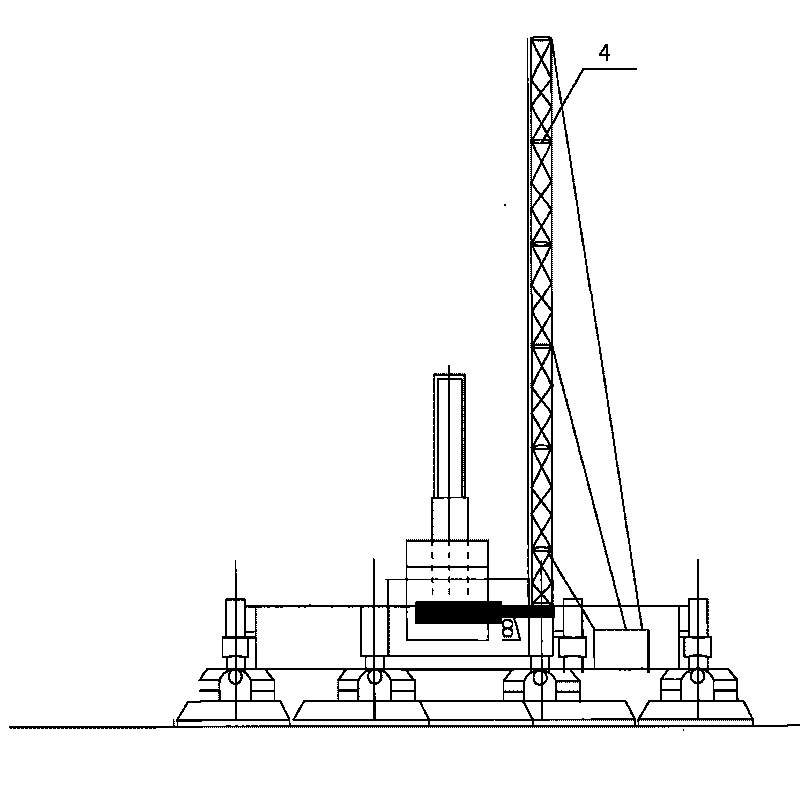

[0017] Embodiment 1. The self-leading hole static pressure pile sinking method in which the spiral pilot hole in the pipe and the static pressure pile sinking are alternately segmented and progressive, wherein: when the static pressure pile sinking is difficult to reach the depth, the cavity placed in the PHC pipe pile 2 is used After the lead hole drill 6 in 3 conducts the lead hole to the foundation, pull the lead hole drill 6 upwards and then carry out static pressure pile sinking; repeatedly and alternately carry out the lead hole, reverse pull, and static pressure pile sinking; until the PHC pipe pile 2 sinking to the design level.

[0018] Static pile sinking refers to the process in which the static pile driver 1 holds the PHC pipe pile 2 tightly and presses the pile downward.

Embodiment 2

[0019] Embodiment 2, the self-leading hole static pressure pile sinking method of alternating and segmented self-leading hole and static pressure pile sinking method in the pipe, the operation steps are as follows:

[0020] Before the static pressure pile sinking, the pilot hole drill 6 is pre-introduced into the cavity 3 of the PHC pipe pile 2; then the static pressure pile sinking is started; After the pilot hole drill 6 in the cavity 3 in the PHC pipe pile 2 carries out the pilot hole to the foundation, after the pilot hole drill 6 is pulled back upwards, the static pressure pile sinking is carried out again; Sink the pile; until the PHC pipe pile 2 sinks to the design elevation.

Embodiment 3

[0021] Embodiment 3. The self-guiding hole static pressure pile sinking method in which the spiral pilot hole in the pipe and the static pressure pile sinking are alternately segmented and progressive, wherein: the pilot hole drill 6 is pre-introduced into the cavity 3 of the PHC pipe pile 2 before the static pressure pile sinking ; Start static pressure pile sinking again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com