A large-span high-strength conjoined greenhouse

A high-strength, long-span technology, applied in horticulture, greenhouse cultivation, climate change adaptation, etc., can solve the inconvenience of the height and inclination angle of the arched roof, the large-scale and mechanized production of the shed are difficult and irreversible The original state and other problems can be achieved to increase the ability to withstand natural disasters again, facilitate mechanized operations, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

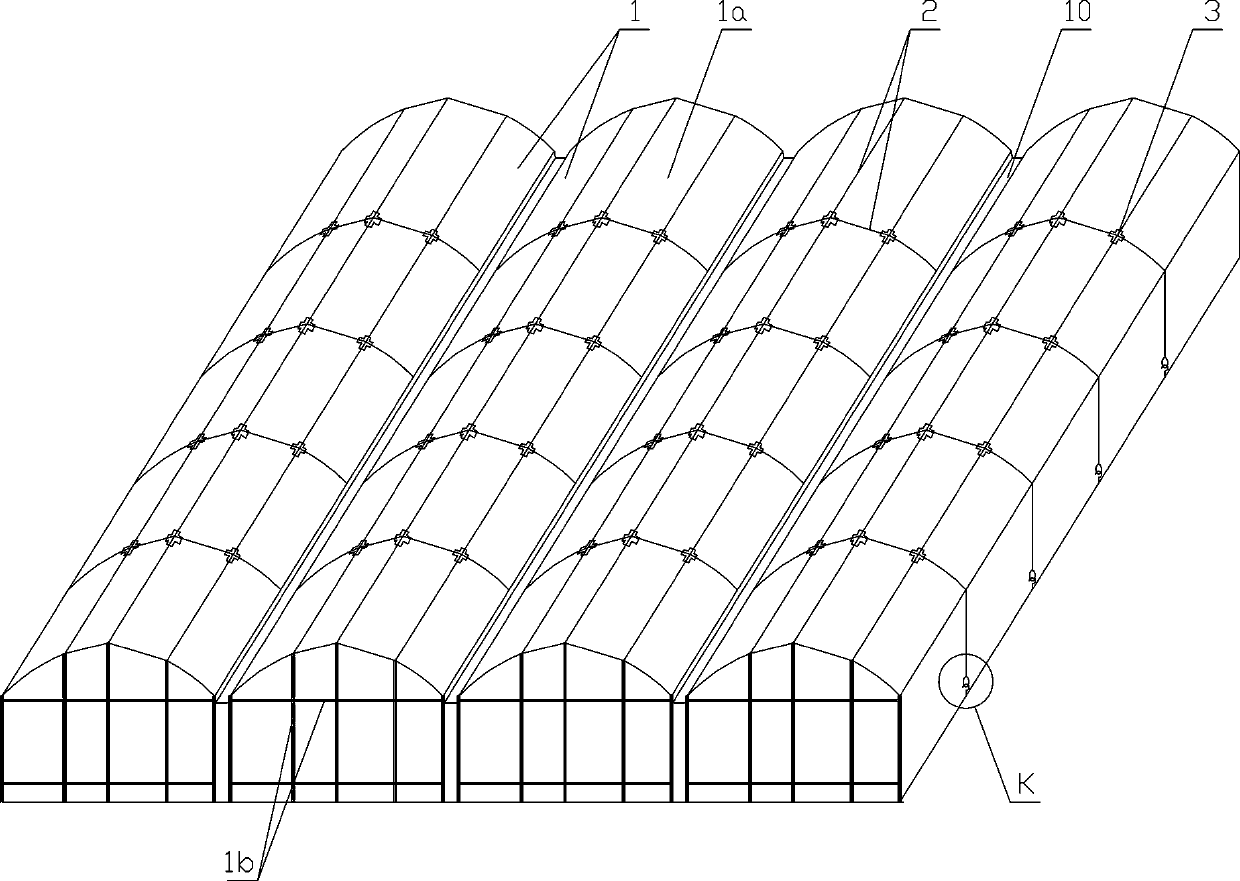

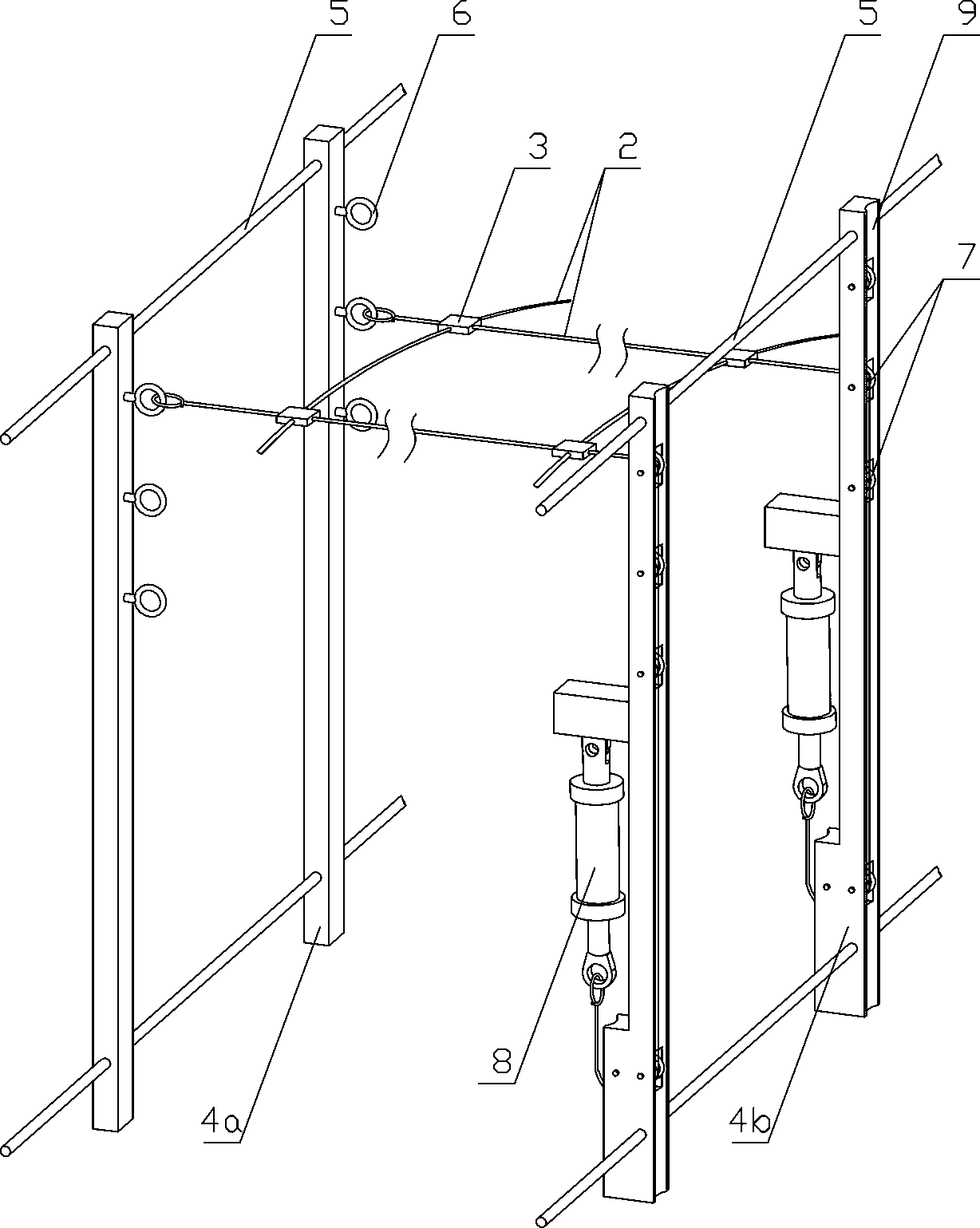

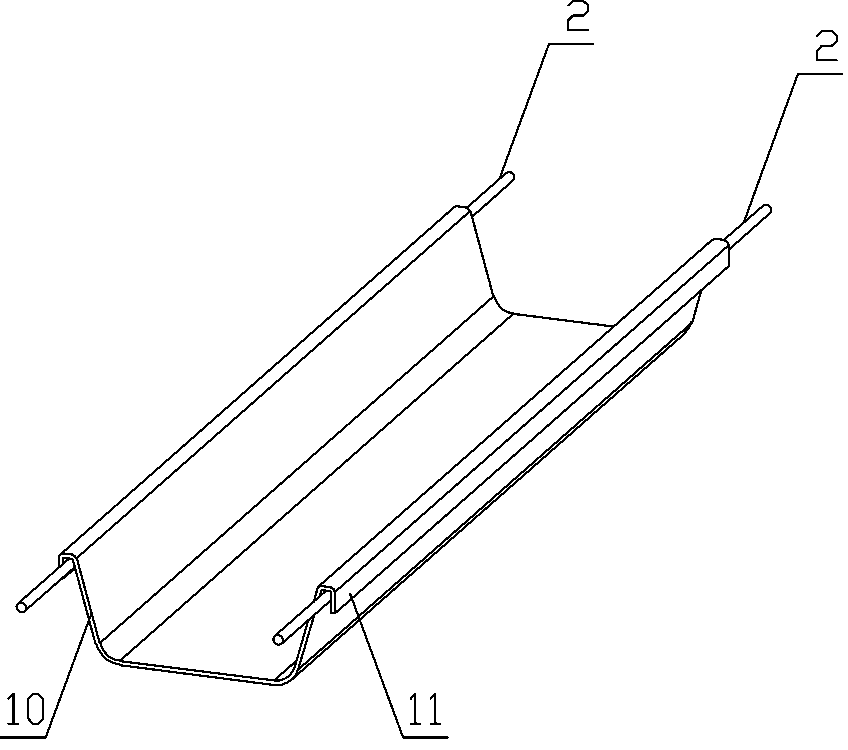

[0022] see figure 1 , figure 2 , the present invention is made up of several span single sheds, each span single shed has a single shed skeleton 1, and the single shed skeleton 1 is made up of an arched roof 1a and a support frame 1b arranged on the front and rear sides of the single shed. Covering materials are arranged on the arched roof 1a, and the arched roof 1a is composed of steel strands 2 arranged vertically and horizontally, wherein the intersecting parts of the steel strands arranged longitudinally and horizontally are fastened and connected by cross fasteners 3 The support frame 1b is composed of several support columns 4a / 4b arranged at equal intervals (the support columns on the front side of the single shed are represented as 4a, and the support columns on the rear side of the single shed are represented by 4b) and transverse connecting rods 5 Fence structure, in which the supporting columns on the front and rear sides of the single shed are in one-to-one corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com