Prefabricated node and prefabricated frame structure and construction method thereof

A node and prefabricated column technology, applied in the direction of construction and building structure, can solve the problems of poor pouring quality, poor durability and reliability, and difficult post-maintenance, so as to save construction cost, improve durability and reliability, and save construction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The prefabricated node and the prefabricated frame structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

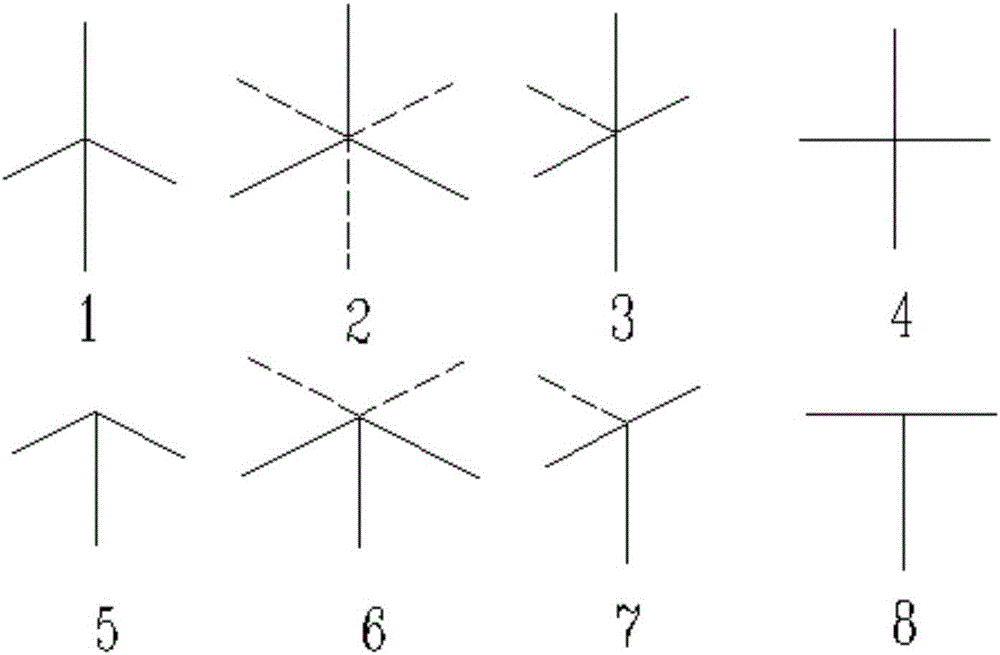

[0043] There are many types of prefabricated nodes provided by the present invention, and eight kinds of prefabricated nodes are given here, which are prefabricated node A 1, prefabricated node B 2, prefabricated node C 3, prefabricated node D 5, prefabricated node E6, prefabricated node Node F7, prefabricated node G4, prefabricated node H8, the structure diagram is as follows figure 1 shown.

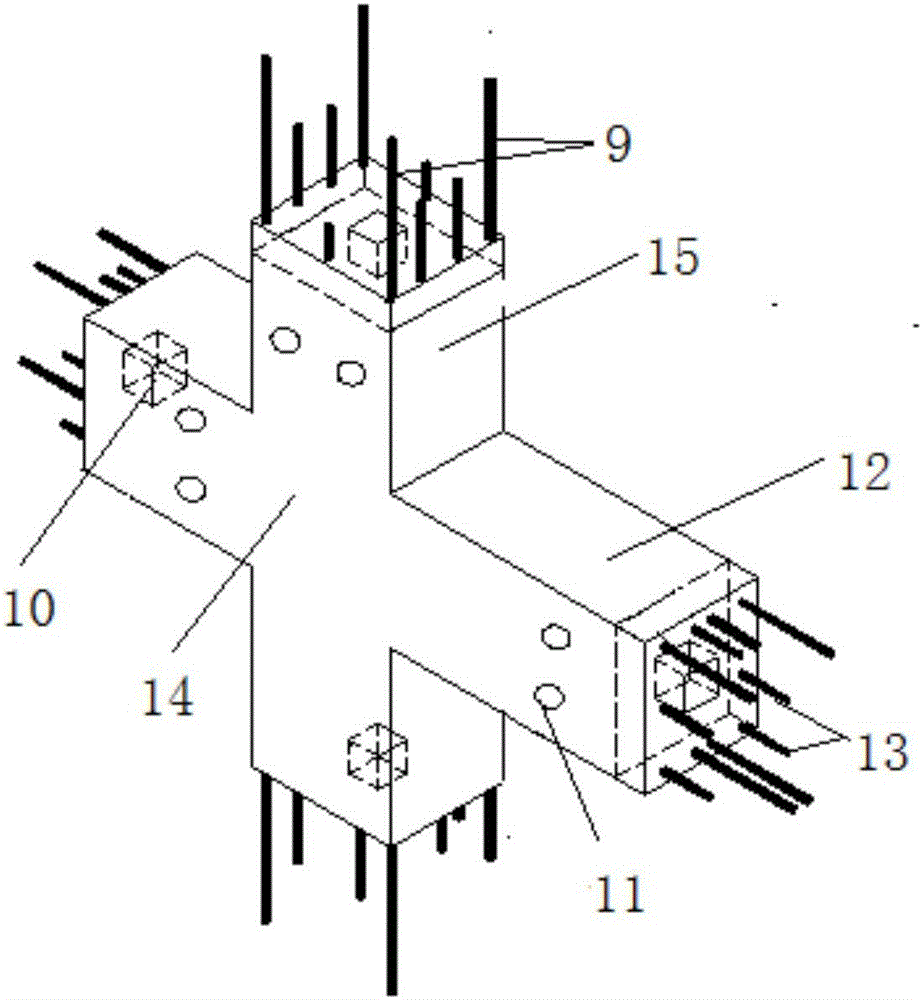

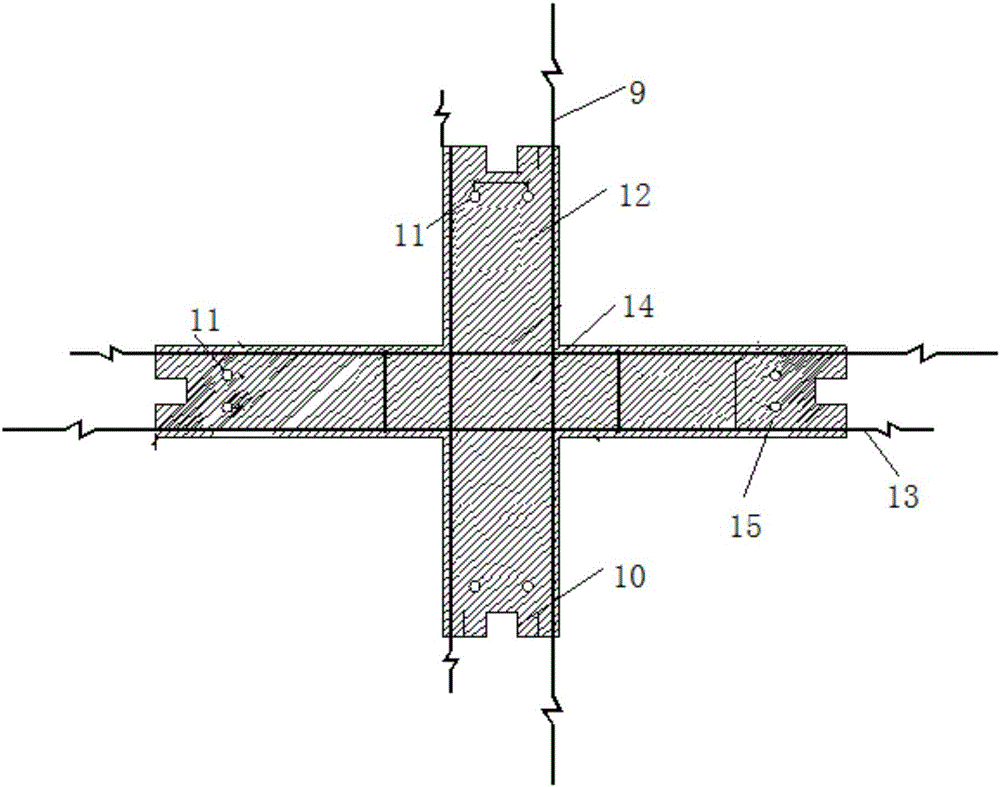

[0044] In order to describe the structure of the prefabricated joints in detail, this embodiment uses the prefabricated joint G as a detailed description. The prefabricated joint G includes a prefabricated beam-column joint 14, two node outrigger beam sections 12 and two node outrigger column sections 15. The prefabricated The beam-column node 14, the 2-node overhanging beam section 12 and the 2-node overhanging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com