High-pressure-bearing square deep foundation pit applicable to water-rich sand gravel stratum and excavation method of high-pressure-bearing square deep foundation pit

A high-pressure, deep foundation pit technology, applied in excavation, infrastructure engineering, protection devices, etc., can solve the problems of high excavation cost, difficulty in excavation, and difficulty in plugging, so as to improve waterproof quality and improve Construction quality, effect of reducing excavation deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following non-limiting examples illustrate the invention.

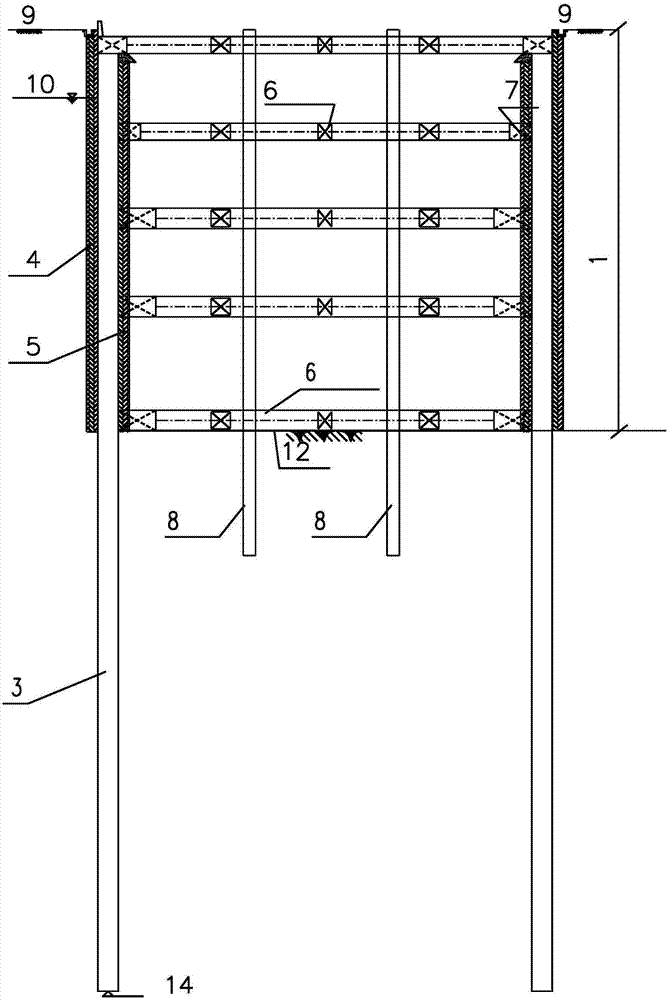

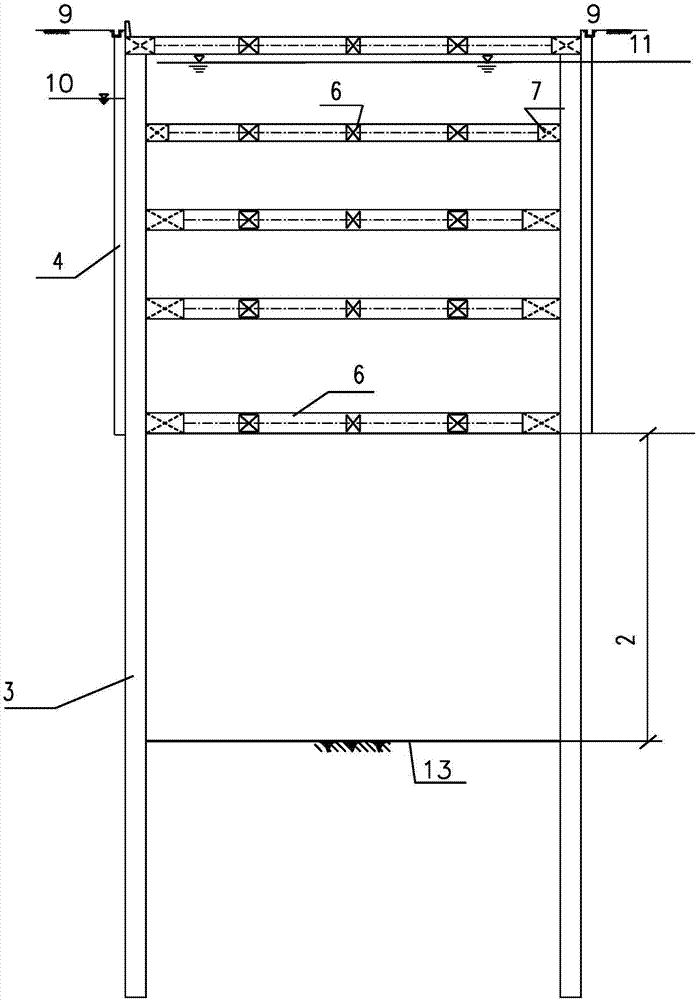

[0049] refer to figure 1 , 2 As shown, a high pressure-bearing square deep foundation pit suitable for water-rich sand eggs, including the dewatering excavation area 1 on the upper part of the foundation pit and the water-bearing excavation area 2 on the lower part of the foundation pit, in the dewatering excavation area 1 is set The dewatering well 8 is provided with the external groove wall reinforcement 4 of the triaxial stirring pile and the internal groove wall reinforcement 5 of the triaxial stirring pile inside and outside the ground connection wall 3 of the entire dewatering excavation area 1, and is also provided in the entire dewatering excavation area 1. At least two reinforced concrete support beams 7 and reinforced concrete supports 6 are provided (five reinforced concrete support beams 7 and reinforced concrete supports 6 have been constructed in the figure of this embodiment); Filtration an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com