Environment-friendly reflective coating

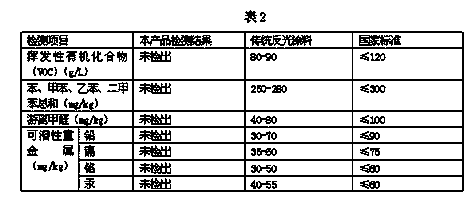

A reflective paint, environmental protection technology, applied in the direction of reflection/signal paint, rosin paint, anti-fouling/underwater paint, etc., can solve the problems of high price, adverse human health, toxicity, etc., and achieve low construction cost, bright and durable colors, Safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: 10% rosin resin, 20% acrylic emulsion, 8% organic pigment, 4% water-based color essence, 43% reflective glass beads, 1% defoamer, 2% plant insect-resistant and bacteriostatic agent, and 2% ethanol and water 10% to obtain the reflective paint, and the fineness of the reflective glass beads is 400 mesh.

Embodiment 2

[0018] Embodiment 2: 20% of rosin resin, 15% of acrylic emulsion, 8% of organic pigment, 2% of water-based color essence, 30% of reflective glass beads, 2% of defoamer, 3% of plant insect-proof and bacteriostatic agent, and 5% of ethanol , water 15% and mix to get reflective paint, the fineness of the reflective glass beads is 450 mesh.

Embodiment 3

[0019] Embodiment 3: 15% of rosin resin, 15% of acrylic acid emulsion, 6% of organic pigment, 3% of water-based color essence, 33% of reflective glass beads, 2% of defoamer, 2% of plant insect-proof and bacteriostatic agent, and 4% of ethanol , water 20% and mix to get the reflective paint, the fineness of the reflective glass beads is 450 mesh.

[0020] The plant insect-proof and bacteriostatic agent is prepared by the following method:

[0021] 1) Crush Pyrethrum diffusa into coarse powder, and pass through a 20-mesh sieve;

[0022] 2) Reflux extraction: reflux extraction of Pyrethrum diffusa coarse powder with 90% ethanol at a temperature of 75-80°C for 2-3 hours to obtain a concentrated solution;

[0023] 3) Macroporous resin adsorption purification: the obtained concentrate is separated and enriched by macroporous adsorption resin, followed by water, 30% hydrous ethanol, 40% hydrous ethanol, 50% hydrous ethanol, 60% hydrous ethanol, and 70% hydrous ethanol. Gradient elu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com