Shield tunneling machine cutter disc used for enriching large-particle-size boulder stratum

A technology of shield cutter head and large particle size, which is applied to mining equipment, earthwork drilling, tunnels, etc., can solve the problems of high construction safety risk, large impact on the surrounding environment, and long construction period, so as to shorten the construction period and reduce construction costs. The effect of cost reduction and construction cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

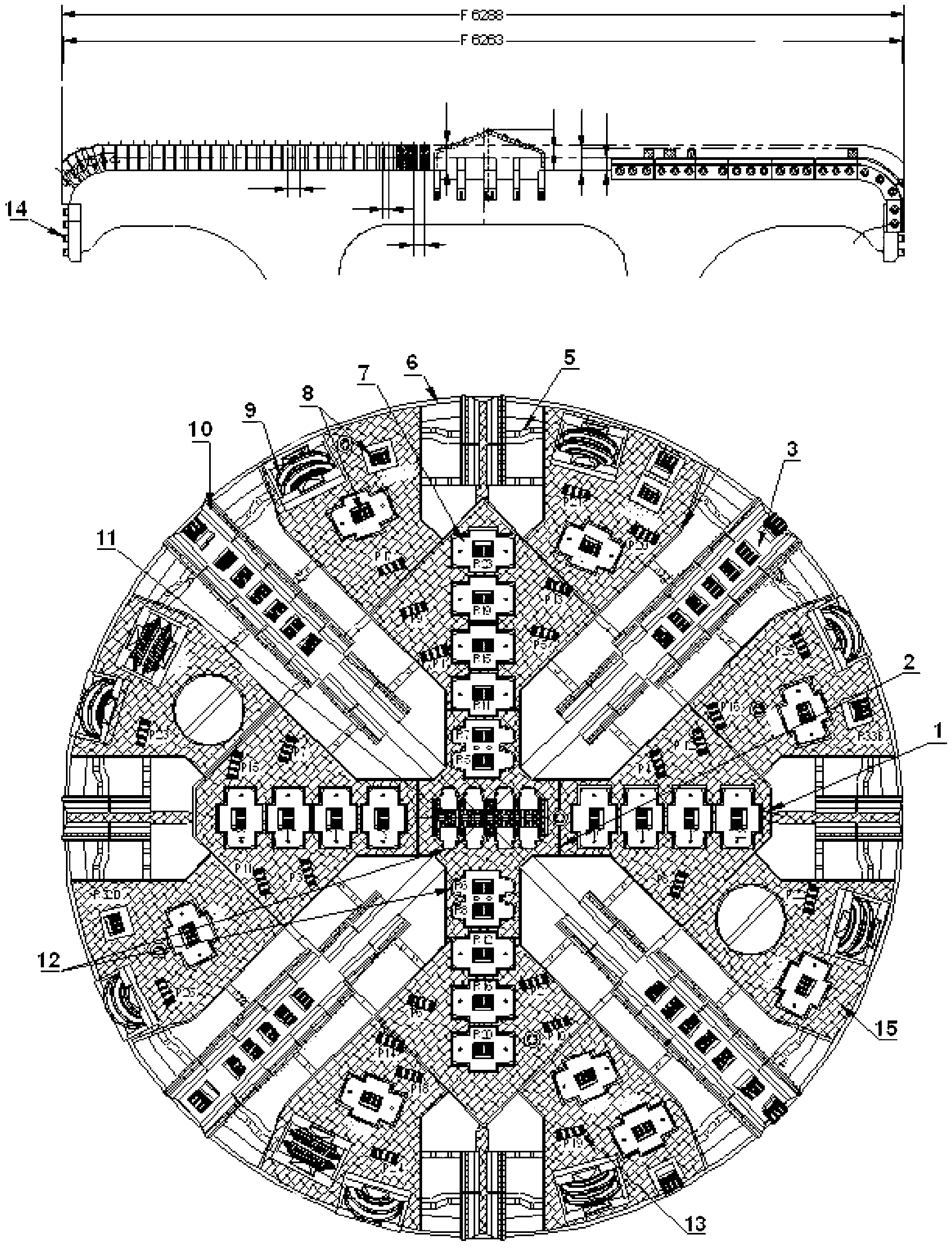

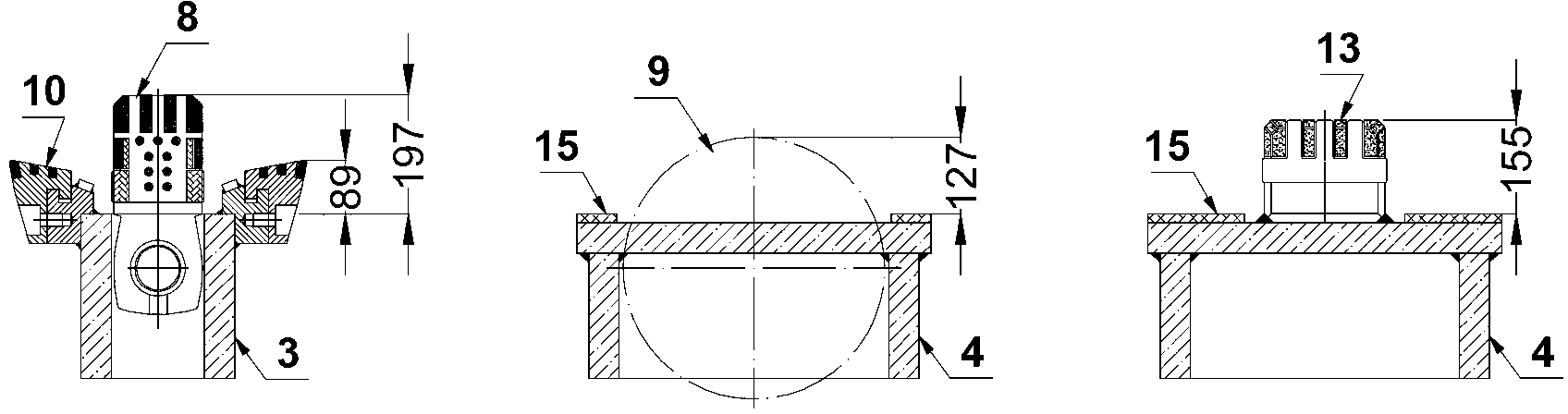

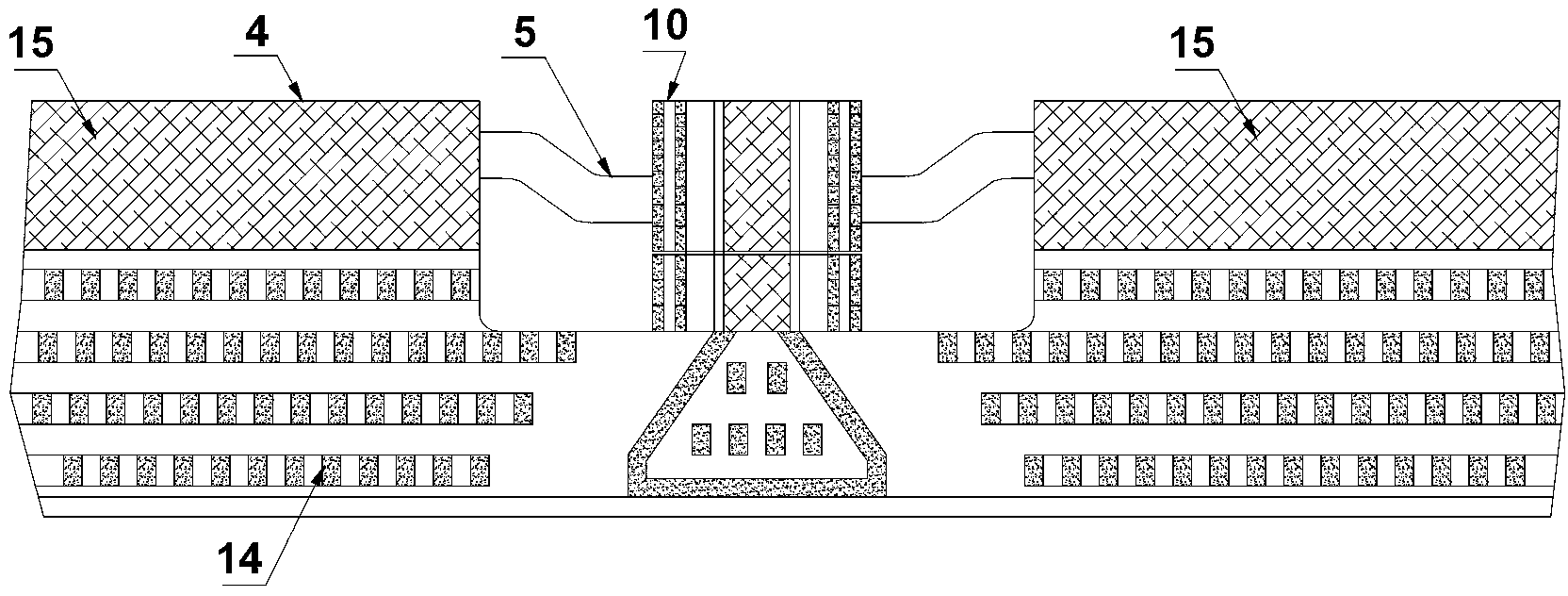

[0014] Embodiment 1: as Figure 1-4 As shown, the shield cutter head for enriching large-sized boulder formations includes a cutter head body and cutters, and four main ribs 2 perpendicular to each other are arranged on the circular cutter head body 1 at the center of the cutter head body. The upper surfaces of the four main ribs 2 form the main rib disk surface, and the main ribs 2 are welded with the circular steel plate 6 of the outer circumference of the cutter head body 1 to form a panel-type shield cutter head; The central positions of the cutter head body 1 intersect each other perpendicularly and are respectively arranged at 45° intervals with the four main ribs 3. The main ribs 2 and the spokes 3 are connected to each other through a steel grid 5, and a heavy-duty Tear knife 8, disc hob 9 and cutter head panel strengthening protection knife 13, are fixed with heavy duty tear knife 8 and scraper 10 above spoke 3;

Embodiment 2

[0015] Embodiment 2: as Figure 1-4 As shown, a double disc hob 12 is installed at the center of the cutterhead body 1, and the rest are as described in Embodiment 1.

Embodiment 3

[0016] Embodiment 3: as Figure 1-4 As shown, the strengthening protection knife 13 is welded on the top of the main rib plate of the cutterhead, and the strip-shaped strengthening protection knife 14 is welded on the outside of the circular ring steel plate 6 of the cutterhead body. The heights of the scraper 10, disc hob 9, reinforced protective knife 13 and heavy tearing knife 8 on the cutter head body 1 are respectively set from low to high, thereby forming a multi-track multi-level cutter arrangement, except that the reinforced protective knife 13 is welded In addition, the scraper 10, the disc hob 9, and the heavy tearing knife 8 all adopt the back-mounted bolt connection installation method, and the cutter can be replaced directly in the shield soil bin. The outer surface of the cutter head body 1 is covered and welded with high strength. Chromium carbide wear-resistant steel plate 15, and the rest are as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com