Anti-sliding device and method for large-gradient shield tunneling machine

A technology of anti-skid device and shield machine, which is applied in the direction of earth drilling, mining equipment, tunnels, etc. It can solve the problems of difficult axis control, slurry leakage, landslide, and difficult establishment of earth pressure balance, etc., and achieves simple structure and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

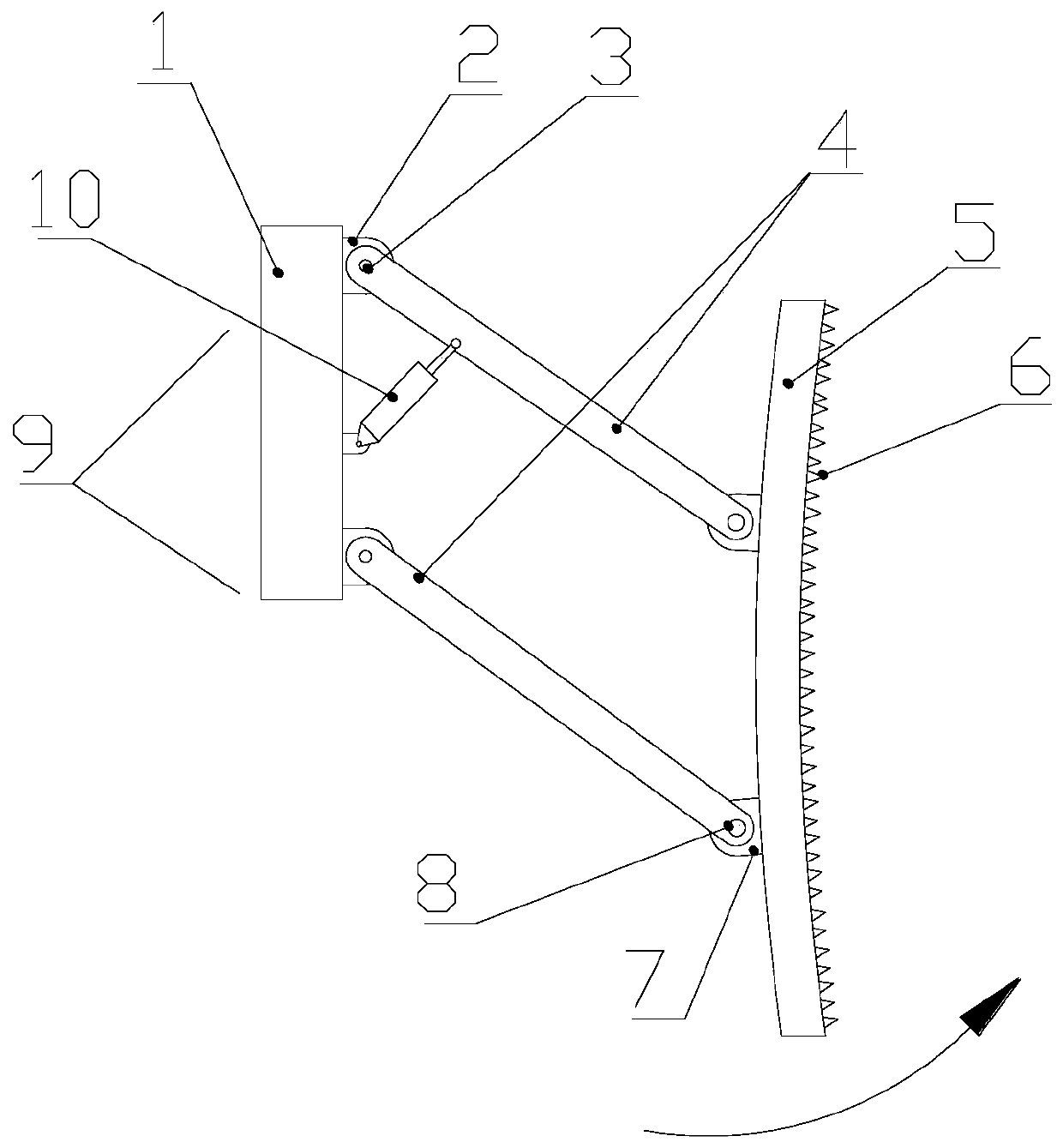

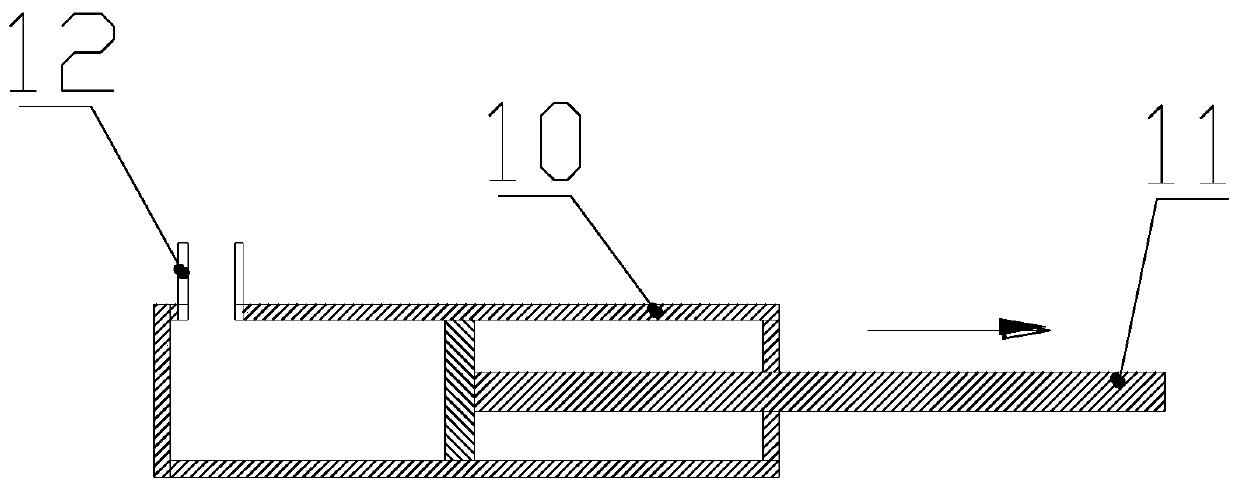

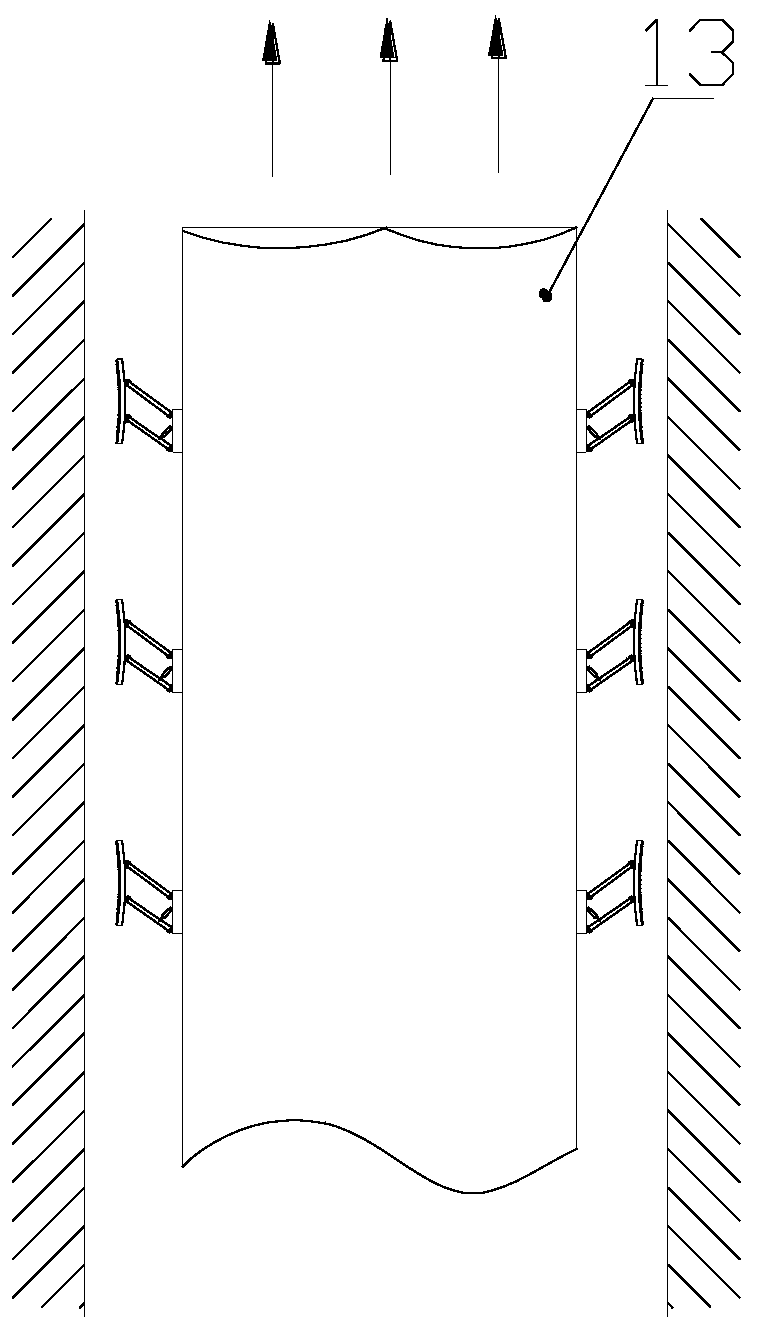

[0033] see figure 1 , an anti-slip device for a large-slope shield machine, including a fixed block 1, a tensioning mechanism, a swing arm mechanism 4, and an anti-slip damping block 5; the anti-slip damping block 5 and the fixed block 1 are connected by a swing arm mechanism 4, and the swing arm mechanism 4 The two ends of the tension mechanism are respectively hinged with the anti-skid damping block 5 and the fixed block 1; the fixed end of the tension mechanism is connected with the fixed block 1, and the tension movable end of the tension mechanism is connected with the swing arm mechanism 4, and the tension movable end pushes the swing The arm mechanism 4 rotates and then drives the anti-skid damping block 5 to move.

[0034] Specifically, the swing arm mechanism 4 provided by the present invention includes a first swing arm and a second swing arm arranged parallel to each other, and the fixed block 1 , the first swing arm, the second swing arm and the anti-slip damping b...

Embodiment 2

[0038] The anti-slip method of the anti-slip device of the present invention is described by taking the anti-slip method of the present invention in the construction process of the mud-reducing effect material on the shield machine as an example.

[0039]The shield construction of a subway project uses mud-reducing materials: during the excavation process, a new type of material is injected radially into the bottom of the front shield and the middle shield of the shield machine to fill the gap between the shield body and the soil in time to prevent The shield machine carries the head, and the attitude of the shield machine is easier to control. The gram mud effect is composed of synthetic calcium-based clay minerals, cellulose derivatives, colloid stabilizers and dispersants.

[0040] The gram mud effect method is to press the two liquids of high-concentration muddy water material and plastic strength regulator (ie water glass) to the designated position through piping, and th...

Embodiment 3

[0049] The tensioning mechanism in the present invention is an electric push rod, which is a new type of electric actuator, mainly composed of a motor, a push rod and a control device, etc., which can realize remote control and centralized control; Make round-trip movements within the stroke. When in use, choose the most commonly used electric push rod on the market, fix one end of the push rod on the fixed block, and fix the other end of the push rod on the first swing arm; when in use, start the motor push rod to push the swing arm mechanism to the right, Thereby the anti-slip damping block is driven to move to the right, and the inverted teeth on the anti-slip damping block are in close contact with the inner wall of the tunnel to prevent sliding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com