Steering wheel sleeve

A steering wheel cover and steering wheel technology, which is applied to the steering control and handwheels installed on the car, can solve the problems of cumbersome leather production methods, non-recyclable use, and low temperature resistance, so as to increase availability and reduce Fatigue degree, the effect of ensuring comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

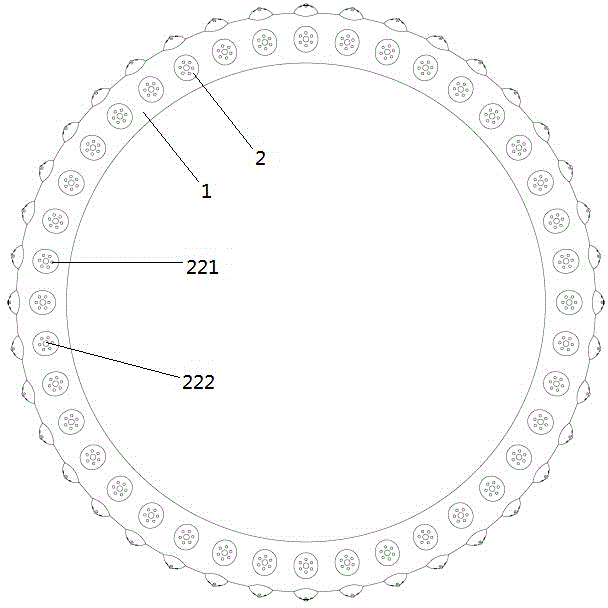

[0062] Such as figure 1 As shown, the outer ring cover body for the steering wheel includes an annular elastic mesh or non-woven fabric ventilation layer 1, and one or more massage parts 2 that are heated, melted, bonded, inlaid or glued on the ventilation layer 1; The massaging member 2 includes a supporting portion 21 and a massaging portion 22 adjacent to each other.

[0063] The setting of the ring-shaped elastic mesh or non-woven fabric ventilation layer 1 of this scheme can increase the friction between the driver's palm and the outer ring casing when driving the vehicle, avoid slipping between the palm and the outer ring casing, and ventilate Layer 1 is made of elastic mesh or non-woven fabric, which can absorb sweat from the palm of the driver and avoid slipping caused by sweat. The elastic mesh or non-woven fabric has air permeability, which increases the air flow while absorbing sweat The circulation of the driver's sweat is alleviated, which not only improves the ...

Embodiment 2

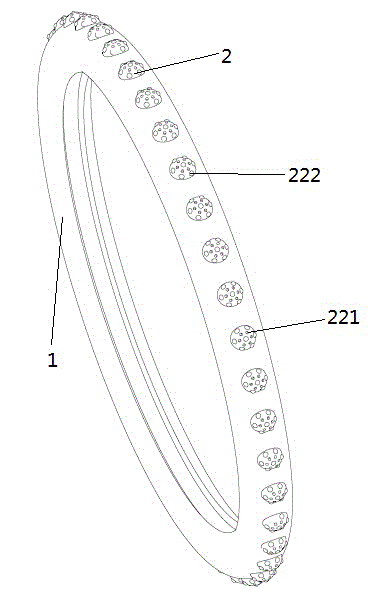

[0068] Such as figure 2 As shown, the outer ring cover body for the steering wheel includes an annular elastic mesh or non-woven fabric ventilation layer 1, and one or more massage parts 2 that are heated, melted, bonded, inlaid or glued on the ventilation layer 1; The massaging member 2 includes a support portion 21 and a massaging portion 22 adjacent to each other.

[0069] The setting of the ring-shaped elastic mesh or non-woven fabric ventilation layer 1 of this scheme can increase the friction between the driver's palm and the outer ring casing when driving the vehicle, avoid slipping between the palm and the outer ring casing, and ventilate Layer 1 is made of elastic mesh or non-woven fabric, which can absorb sweat from the palm of the driver and avoid slipping caused by sweat. The elastic mesh or non-woven fabric has air permeability, which increases the air flow while absorbing sweat The circulation of the driver's sweat is alleviated, which not only improves the saf...

Embodiment 3

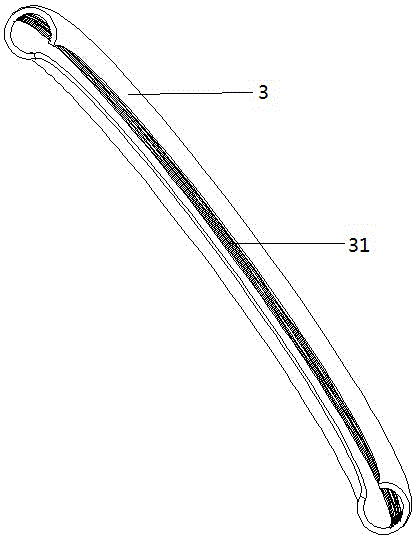

[0075] Such as image 3 and Figure 4 as well as Figure 5 As shown, a steering wheel cover includes a plastic or rubber non-slip layer 3 with a ring-shaped inner liner for fixing and shaping, a ring-shaped elastic mesh or non-woven fabric ventilation layer 1, and heating fusion bonding, inlay connection or glue One or more massaging parts 2 glued on the ventilation layer 1; the massaging parts 2 include adjacent support parts 21 and massage parts 22.

[0076] In this solution, the anti-slip layer 3 provided with a ring-shaped inner lining for fixing and shaping is elastic, convenient to put on the steering wheel, and can well prevent the driver from slipping between the steering wheel and the steering wheel cover when using the steering wheel cover Phenomenon, so as to better ensure the safety of the driver when driving. The setting of the ring-shaped elastic mesh or non-woven fabric ventilation layer 1 of this scheme can increase the friction between the driver's palm and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com