Lubricating oil for automobile chassis stamping parts

A technology for automobile chassis and stamping parts, applied in the field of lubricating oil, can solve the problems of serious carbon deposition, difficult long-term use of biological base oil, and unstable properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

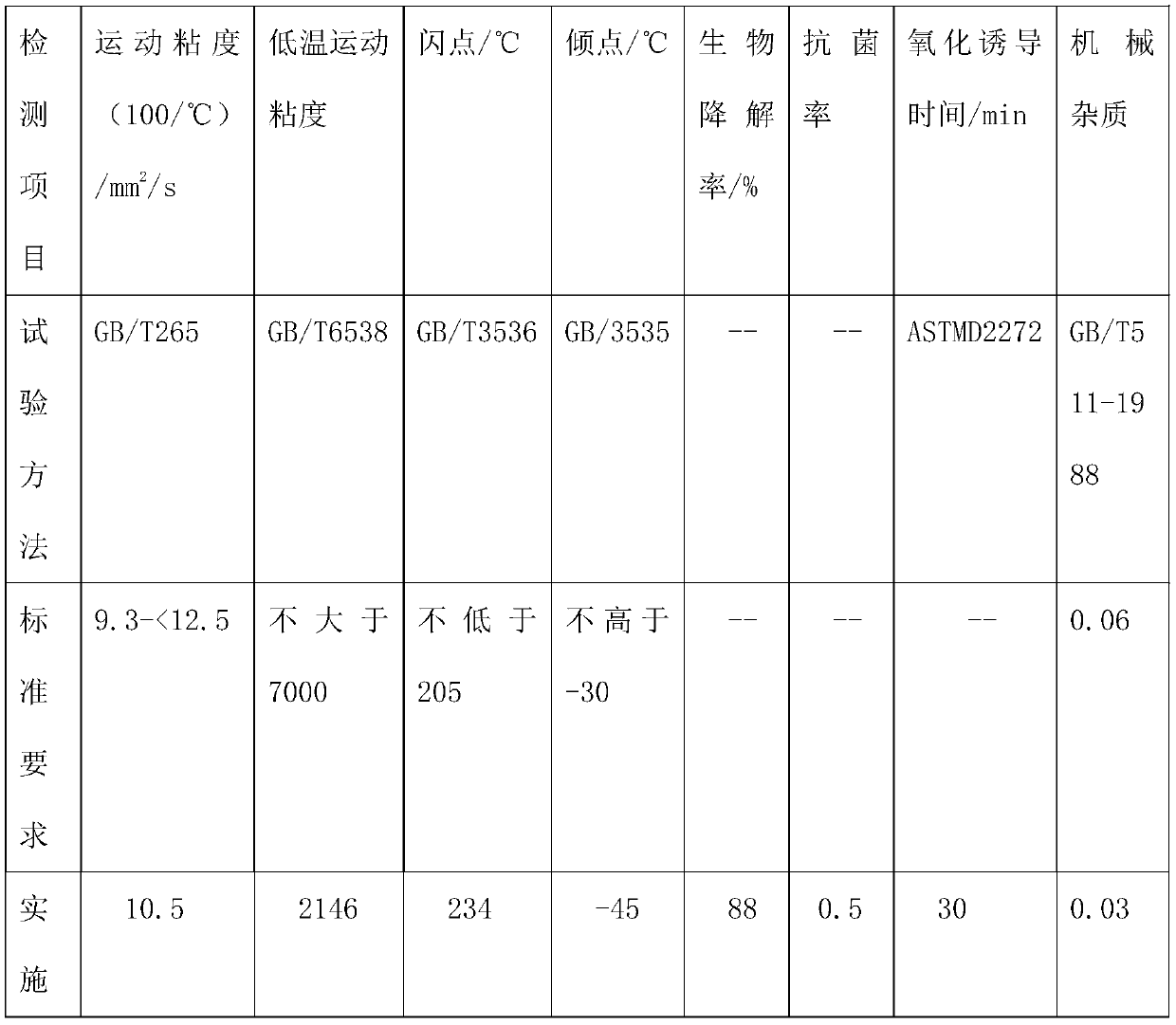

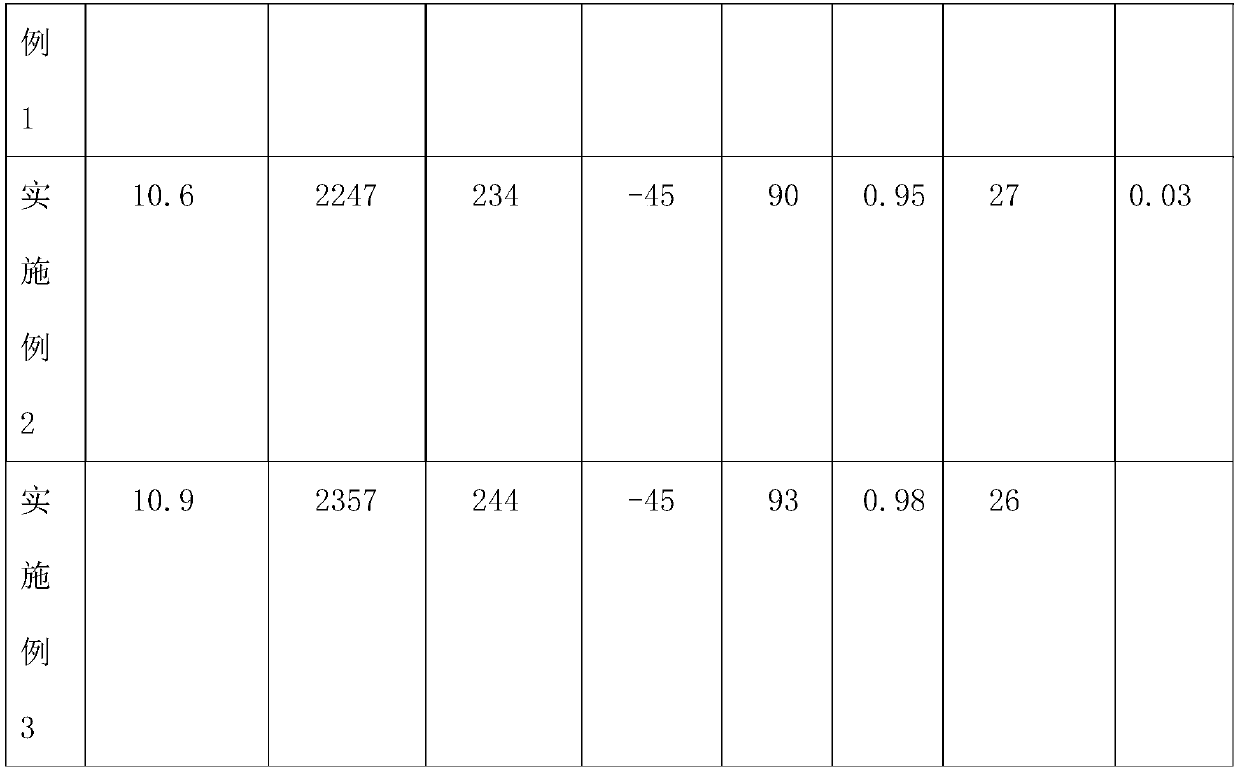

Embodiment 1

[0020] Embodiment 1: a kind of lubricating oil for automobile chassis stamping parts, including biological base oil and additive, the mass ratio of biological base oil and additive is 7:3, and biological base oil comprises high oleic sunflower oil, castor oil, soybean oil , the biological base oil includes the following components by weight: 100 parts of high oleic sunflower oil, 50 parts of castor oil, 50 parts of soybean oil; additives include antioxidants, organic amine preservatives, antiwear agents, antifoam agent, rust inhibitor, flame retardant, pour point depressant, extreme pressure agent, viscosity index improver, pour point depressant, metal deactivator, emulsifier.

[0021] The additives include the following components by weight: 3 parts of antioxidant, 2 parts of organic amine preservative, 5 parts of antiwear agent, 2 parts of antifoaming agent, 2 parts of rust inhibitor, 2 parts of flame retardant, pour point depressant 2 parts of agent, 2 parts of extreme pres...

Embodiment 2

[0031] Embodiment 2: a kind of lubricating oil for automobile chassis stamping parts, including biological base oil and additive, the mass ratio of biological base oil and additive is 7:3, and biological base oil comprises high oleic sunflower oil, castor oil, soybean oil And saponin oil, biological base oil includes the following components by weight: 100 parts of high oleic sunflower oil, 50 parts of castor oil, 30 parts of soybean oil, 20 parts of saponin oil; additives include antioxidant, organic Amine preservatives, detergent dispersants, antiwear agents, antifoam agents, rust inhibitors, flame retardants, pour point depressants, bacteriostats, extreme pressure agents, viscosity index improvers, pour point depressants, metal deactivators , Emulsifier.

[0032] The additives include the following components by weight: 3 parts of antioxidant, 2 parts of organic amine preservative, 3 parts of cleaning and dispersing agent, 5 parts of antiwear agent, 2 parts of antifoaming a...

Embodiment 3

[0044] Embodiment 3: a kind of lubricating oil for automobile chassis stamping parts, including biological base oil and additive, the mass ratio of biological base oil and additive is 7:3, and biological base oil comprises high oleic sunflower oil, castor oil, soybean oil And saponin oil, the biological base oil includes the following components by weight: 100 parts of high oleic sunflower oil, 30 parts of castor oil, 30 parts of soybean oil, 40 parts of saponin oil; additives include antioxidant, organic Amine preservatives, detergent dispersants, antiwear agents, antifoam agents, rust inhibitors, flame retardants, pour point depressants, bacteriostats, extreme pressure agents, viscosity index improvers, pour point depressants, metal deactivators , Emulsifier.

[0045] Further, the additive includes the following components by weight: 3 parts of antioxidant, 2 parts of organic amine preservative, 5 parts of detergent and dispersant, 5 parts of antiwear agent, 2 parts of antif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com