Method for finishing upper groove and narrow slit of workpiece

A technology for narrow slits and workpieces, which is applied in the field of finishing grooves and narrow slits on workpieces. It can solve problems such as inaccessibility of finishing equipment and tools, defects in the appearance of manufactured products, and low transmission accuracy, so as to improve mechanical and physical properties and facilitate operation. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

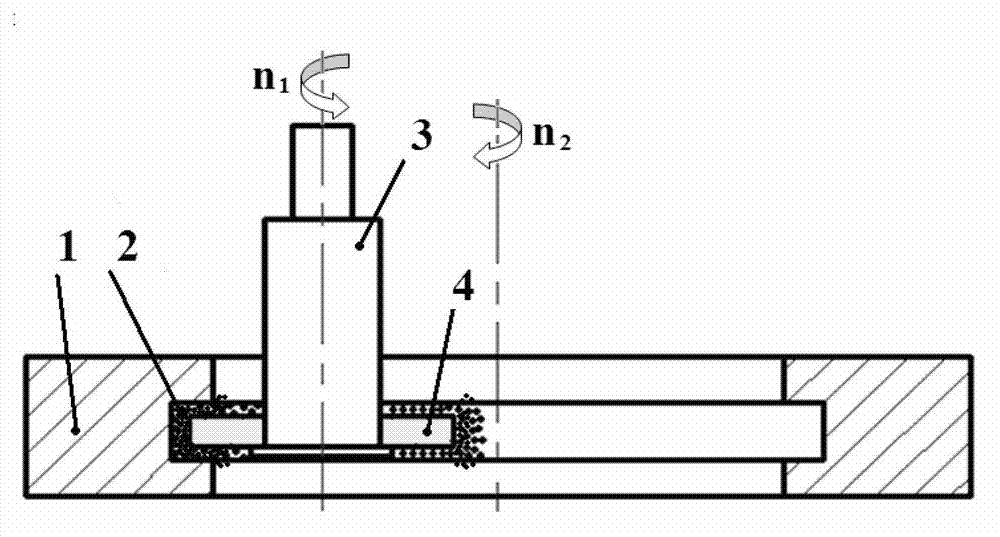

[0024] Such as figure 1 As shown, the method for finishing the rectangular groove of P20 die steel workpiece.

[0025] (1) Using equipment and materials

[0026] A refitted vertical milling machine is adopted, the spindle speed ranges from 300 to 3000r / min, the workpiece positioning frame adopts K11 series standard three-jaw self-centering chuck, and its flip angle is adjustable, driven by a three-phase AC motor with a speed of 50 ~300r / min, can adjust forward and reverse.

[0027] The annular permanent magnet 4 is made of NdFeB, magnetized radially, and the size is The magnetic chuck 3 is connected to the main shaft of the vertical milling machine, and is driven to rotate by the main shaft. The magnetic abrasive grains 2 used are composite grains of iron grains and aluminum oxide grains prepared through briquetting, sintering, crushing and screening processes.

[0028] (2) Operation steps

[0029] Workpiece 1 has a rectangular ring groove, the size of which is The wor...

Embodiment 2

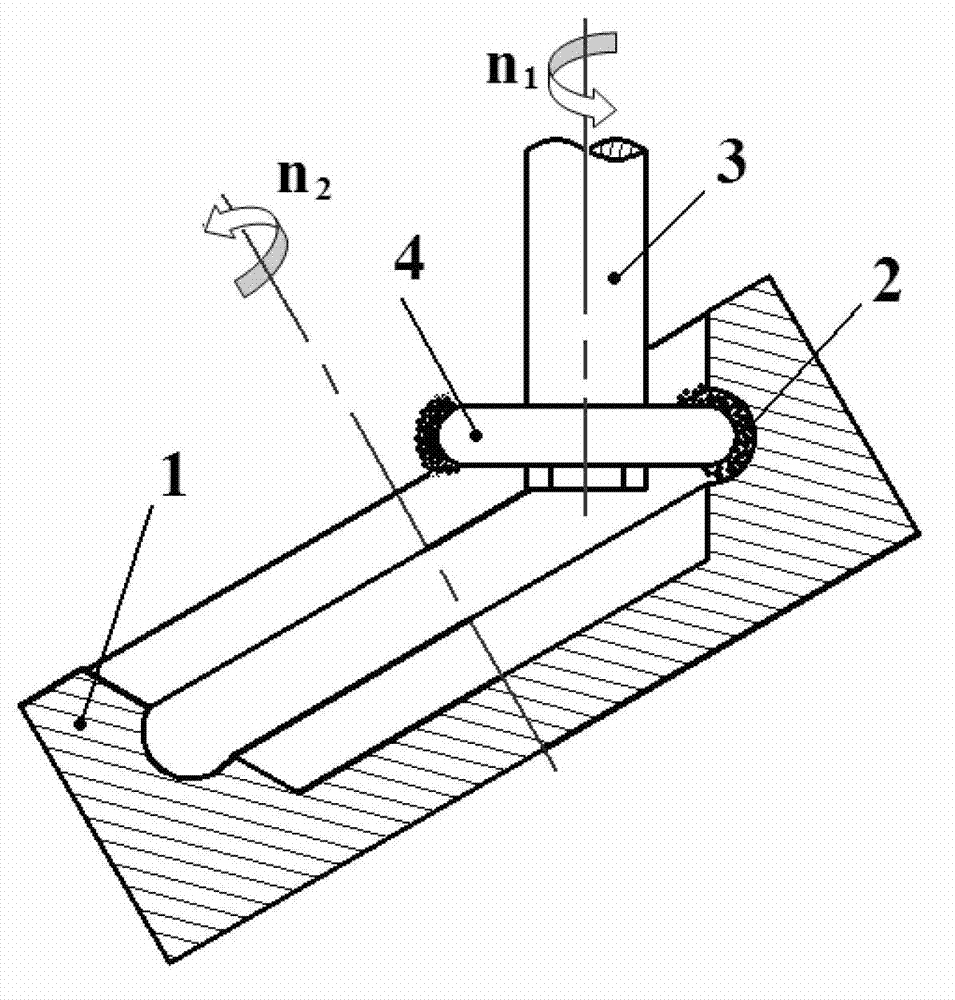

[0031] Such as figure 2 As shown, the method for finishing the curved chute of P20 die steel workpiece.

[0032] (1) The equipment and materials used are the same as in Example 1.

[0033] (2) Operation steps:

[0034] The workpiece 1 has an arc-shaped ring groove, the radius of curvature of the arc is r=1.2mm, and the diameter of the arc top is The workpiece 1 is fixed by the chuck of the positioning frame, and is driven by the motor to rotate at a speed n 2 =300r / min. The permanent magnet 4 is made of NdFeB, ring-shaped, and the diameter of the inner surface is The outer surface is a semi-arc surface, the radius of curvature r=1.2mm, and the diameter of the arc top is The thickness is 1.5mm. The permanent magnet 4 is connected to the main shaft of the milling machine by the magnetic chuck 3, and is driven to rotate by the main shaft at a speed n 1 =1300r / min. Adjust the angle of the positioning frame so that the gap between the arc-shaped surface of the permanent...

Embodiment 3

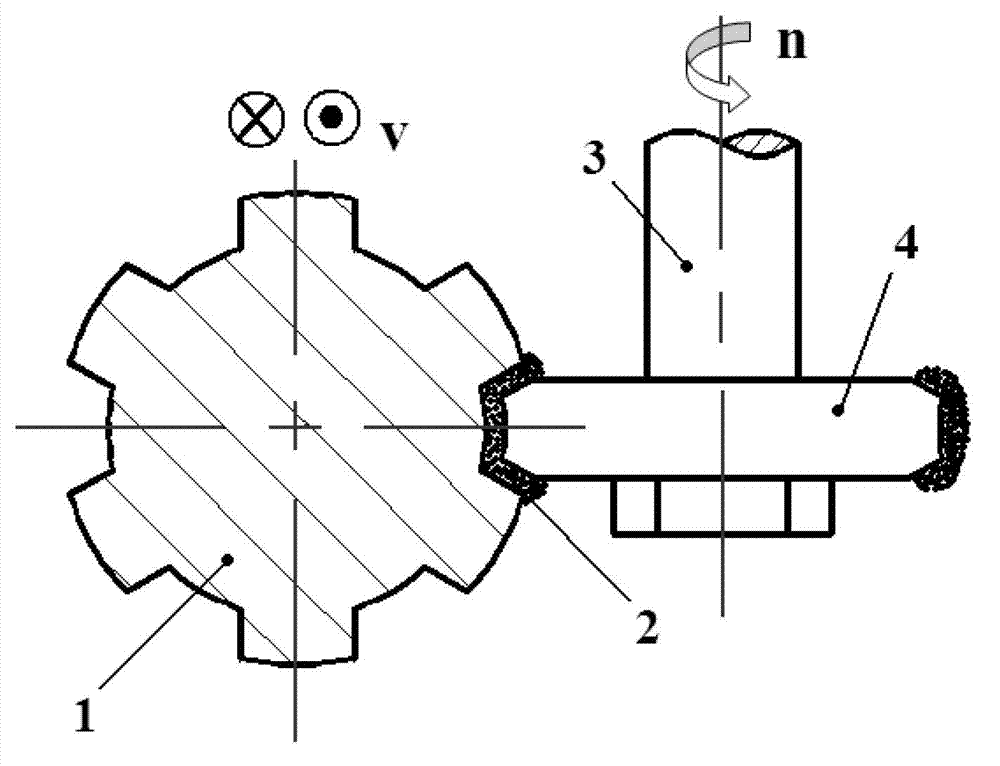

[0036] as attached image 3 As shown, the method of finishing the rectangular spline groove on the workpiece.

[0037] (1) The equipment and materials used are the same as in Example 1.

[0038] (2) Operation steps:

[0039] Workpiece 1 is a rectangular spline shaft made of 45 steel with a size of 6-20×25×6mm. Workpiece 1 is fixed by the chuck of the positioning frame and driven by the positioning frame to reciprocate along the axial direction. The moving speed is v= 1mm / s. The permanent magnet 4 is made of NdFeB, ring-shaped, and the diameter of the inner surface is The outer surface is a semi-arc surface, the radius of curvature r=10mm, and its thickness is 4mm. The permanent magnet 4 is connected to the main shaft of the milling machine by the magnetic chuck 3, and is driven to rotate by the main shaft at a speed n=1300r / min. Adjust the angle of the positioning frame so that it maintains a 1mm gap with the bottom of the spline groove of the workpiece 1 and both sides ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com