Coupling screw for shear bodies

A technology for connecting screws and scissor bodies, which is applied in pivot connection, metal processing, etc., can solve the problems of scissors being scrapped, unusable, and wasted, and achieves the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described below in conjunction with accompanying drawing.

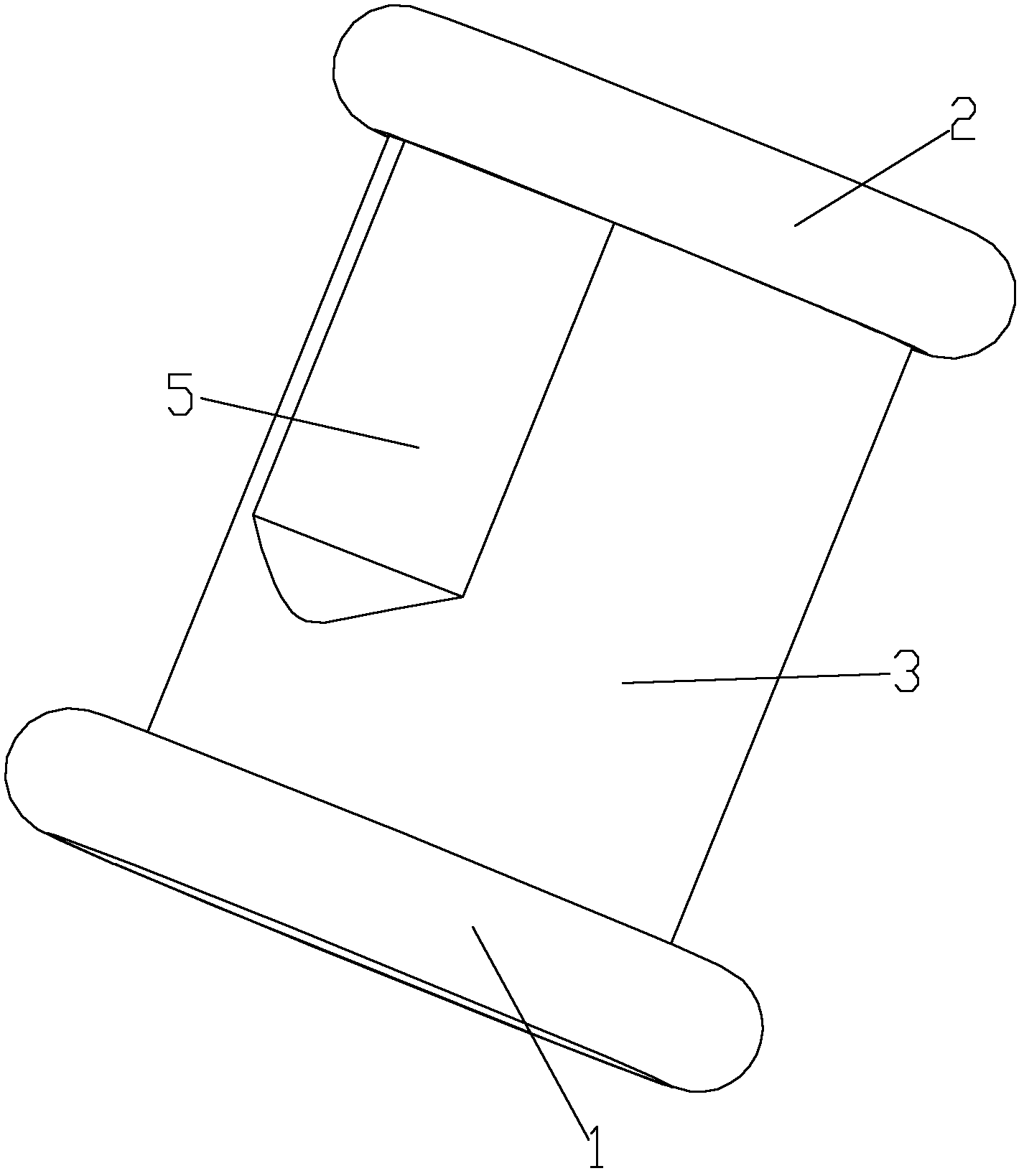

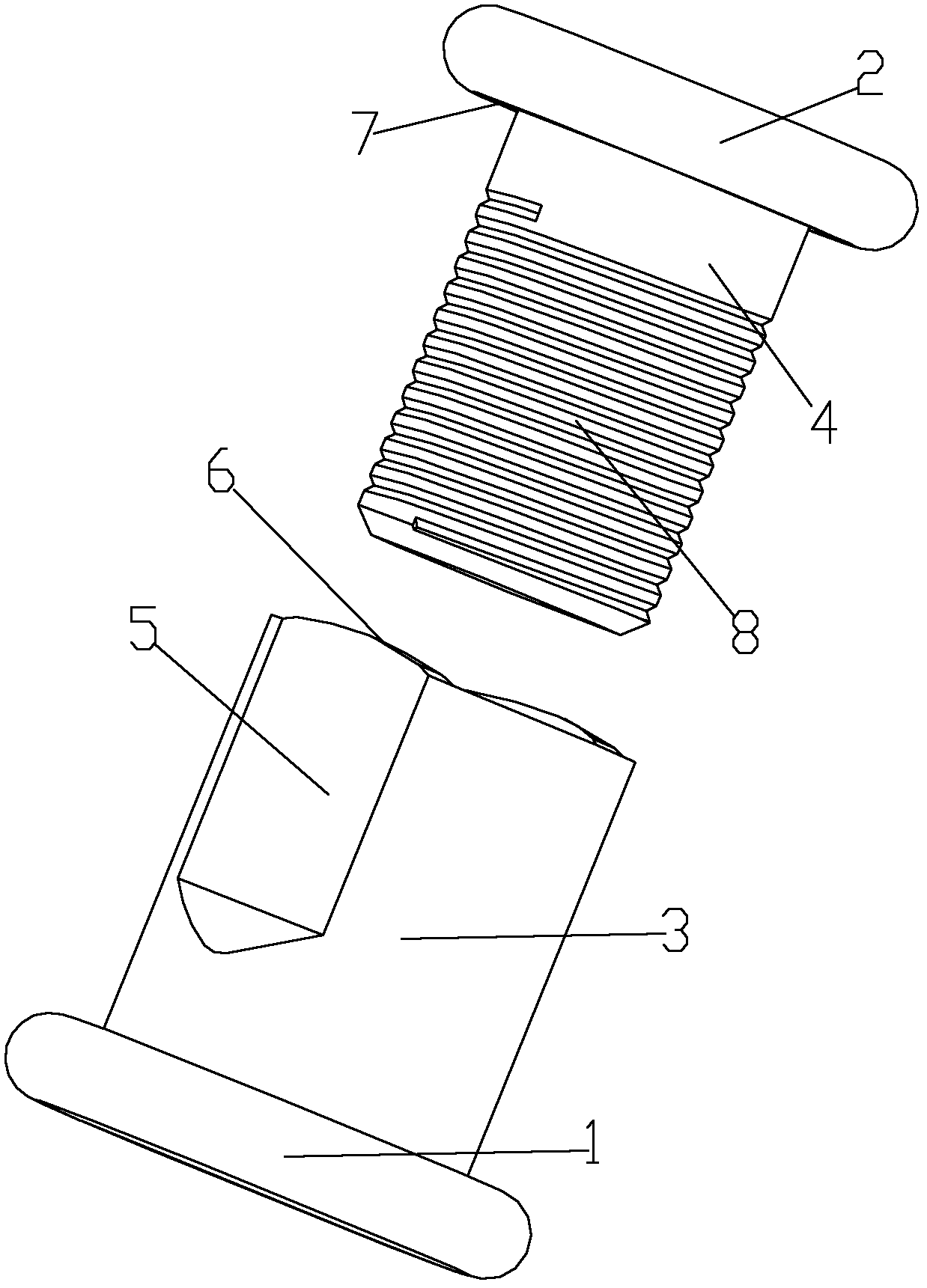

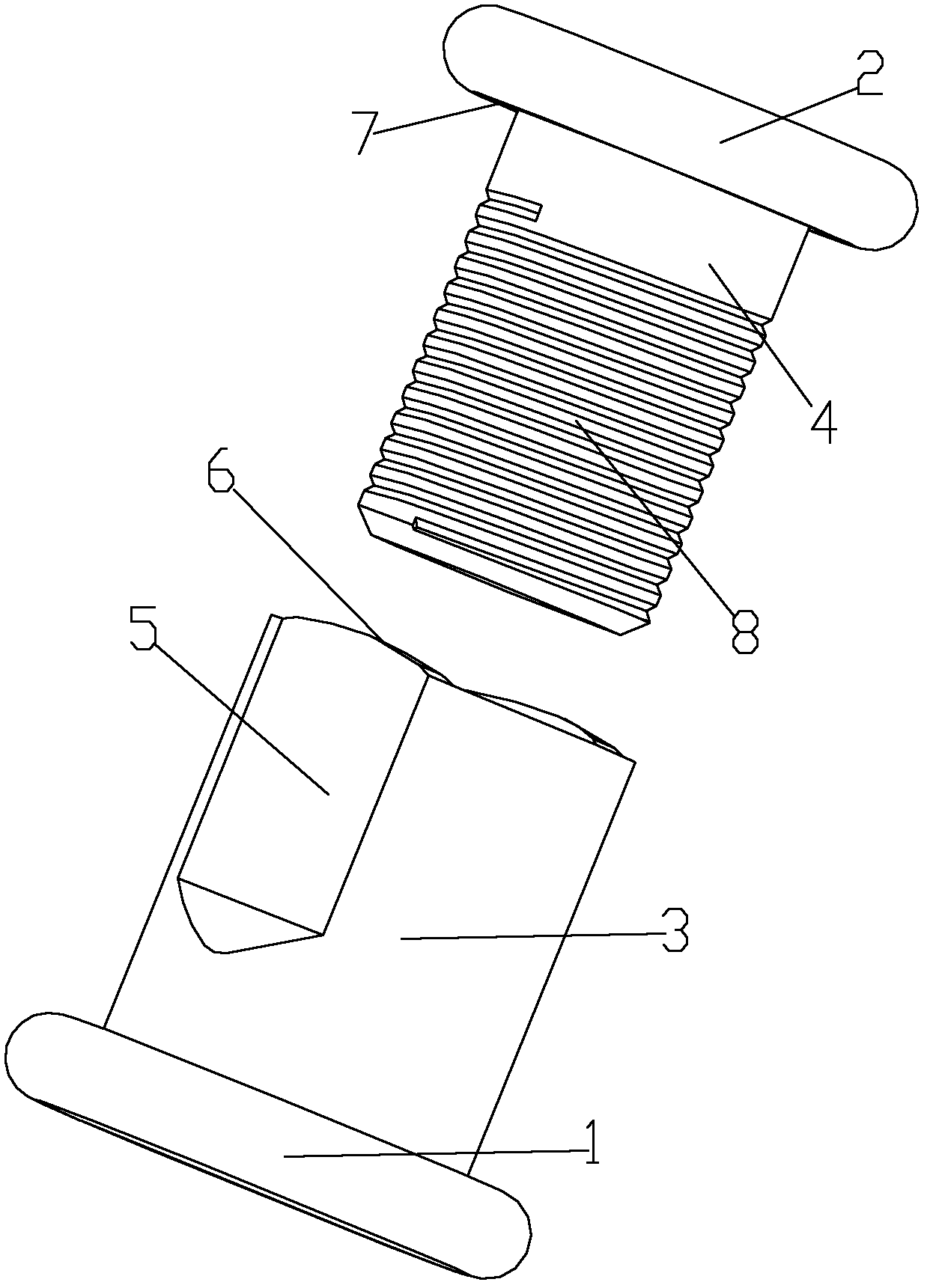

[0013] attached figure 1 It is a connecting screw for a scissors body according to the present invention, comprising a female nail and a sub-nail connected in the female nail, the female nail is composed of a head and a connecting part; the connecting part 3 of the female nail is cylindrical , the inner wall of the cylinder is provided with internal threads, and the outer wall of the cylinder is symmetrically provided with two straight ends 5; the end surface of the connecting part 3 of the female nail is provided with a protrusion 6; the sub-nail is also composed of a head and a connecting part; the sub-nail The connecting part 4 is cylindrical, and its upper end is provided with an external thread 8 that matches the internal thread of the female nail; the end surface of the head of the sub-nail 2 is provided with a groove 7 that matches the protrusion 6; The outer walls of the part 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com