Fast automatic disassembling structure of toilet bowl cover plate assembly

A technology of automatic disassembly and assembly of cover plates, which is applied to the seat or cover for toilets, household appliances, sanitary equipment, etc., can solve the problems of inconvenient cleaning, residual dirt, time-consuming and laborious operation, etc. Sex, the effect of preventing residual

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with specific embodiments.

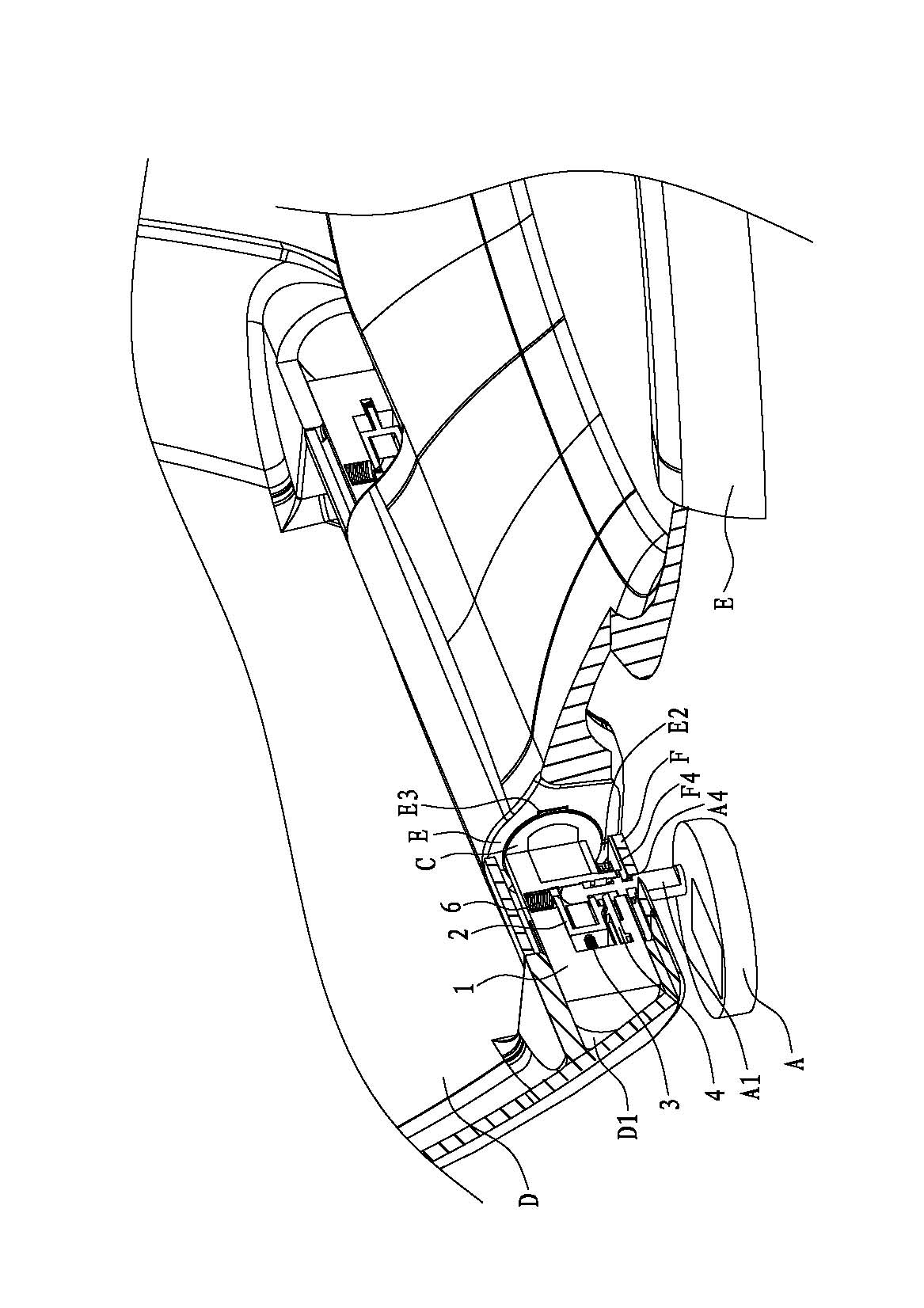

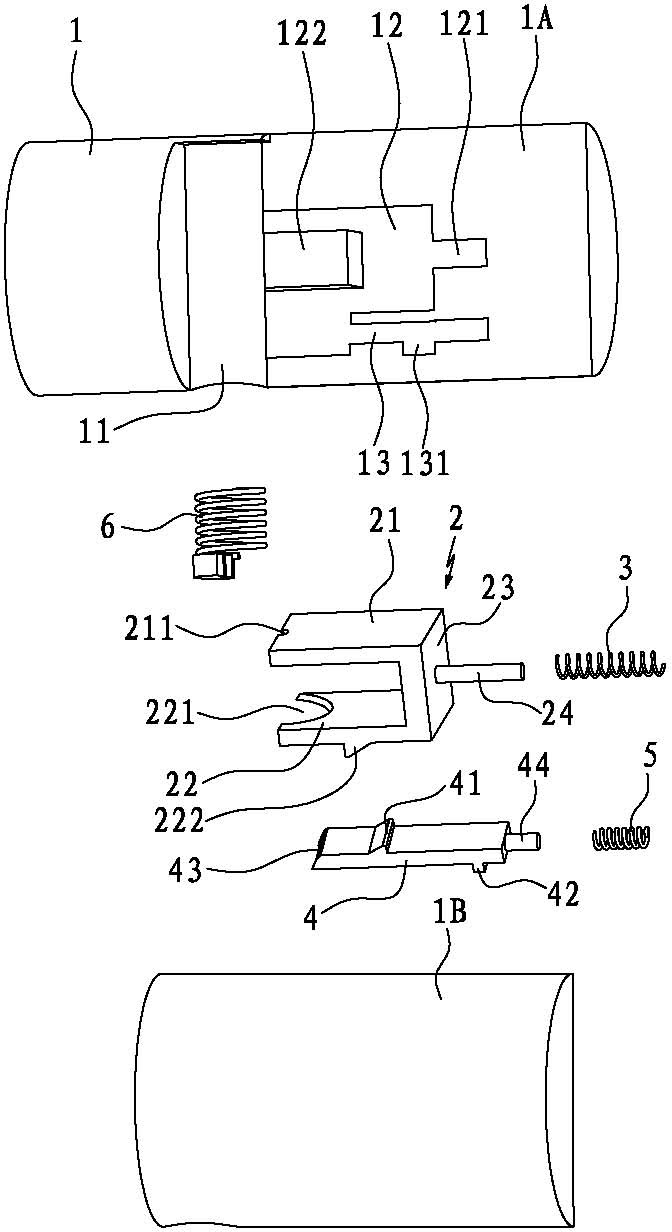

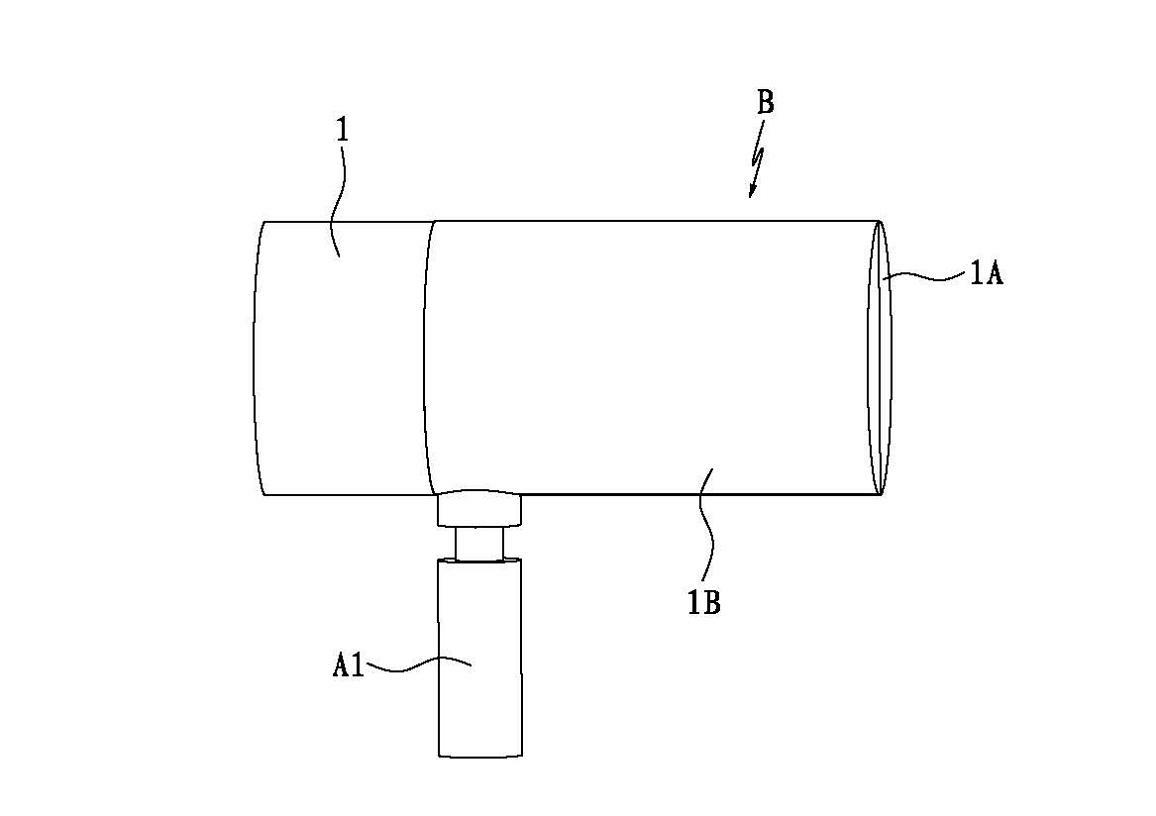

[0040] Such as figure 1 , figure 2 As shown, the present invention discloses a quick automatic assembly and disassembly structure of the toilet cover set, which implements the toilet by pivotally connecting two automatic mechanisms B of the cover set and a connecting shaft, and cooperating with two bases A fixed on the toilet. The automatic quick disassembly and quick installation function of the cover plate group and the toilet.

[0041] The base A is provided with a positioning rod A1, the upper part of the positioning rod A1 is radially provided with a constriction A2, and a positive cone A3 with an inclined guide surface is formed at the upper end of the constriction A2, and the constriction A2 of the positioning rod A1 A ring groove A4 is further provided below.

[0042]The toilet cover set includes a cover D, a ring E and two matching rings F. The rear part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com