Magnet mold pressing device capable of accelerating cooling and facilitating material taking

An accelerated cooling and easy-to-take technology, applied in the direction of visible signal devices, signal devices, measuring devices, etc., can solve the problems of lack of temperature detection warning structure, lack of rapid cooling structure, lack of easy-to-install structure, etc., to speed up the cooling speed , Easy to take the mold, speed up the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

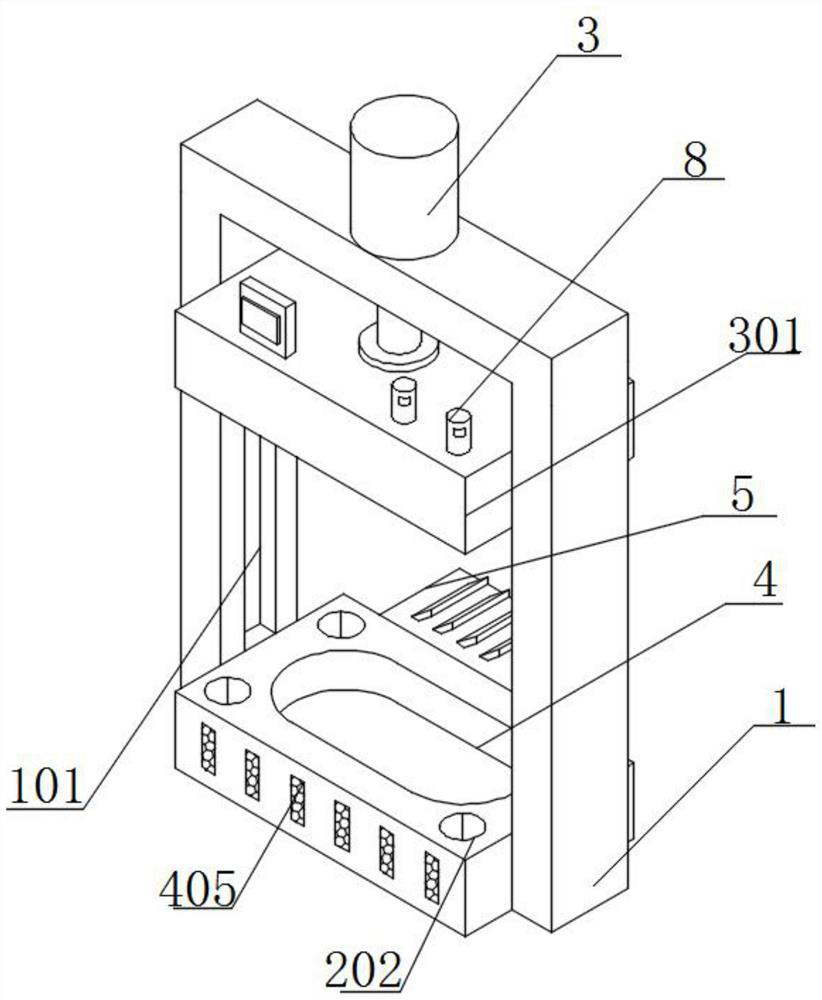

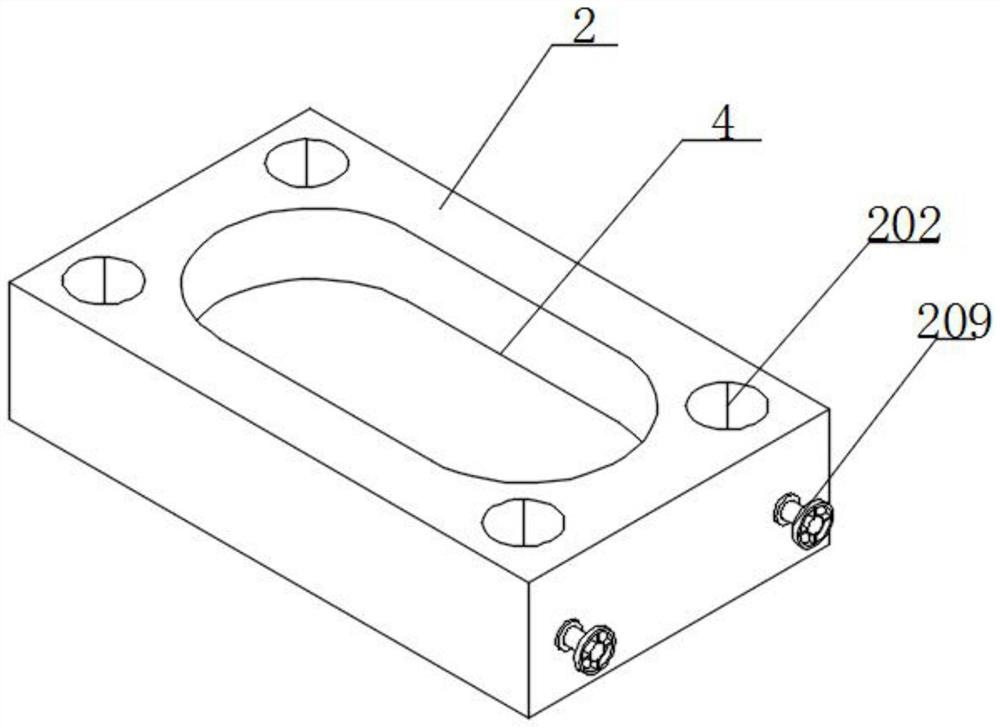

[0044] Example 2: see figure 2 and Figure 4 , an embodiment provided by the present invention: a convenient reclaiming magnet molding device for accelerated cooling, the top of the bottom mold 2 is provided with a mounting hole 202, and the inner wall of the mounting hole 202 is mounted with a plurality of inclined plates 203 through a rotating shaft, and the inclined plate 203 is installed on the inner wall of the bottom mold 2 A first spring 204 is installed on the outer wall of the plate 203, and one end of the first spring 204 is connected to the inner wall of the installation hole 202. The outer wall of the inclined plate 203 is installed with a retractable cable 207, and the outer wall of the retractable cable 207 is sleeved with a clamping block 201 , the inner wall of the installation hole 202 is installed with the rewinding shaft 205, and the retractable cable 207 is wound on the outer wall of the reeling shaft 205, one end of the inclined plate 203 is installed wit...

Embodiment 3

[0045] Example 3: see Figure 5 and Image 6 , an embodiment provided by the present invention: a convenient reclaiming magnet molding device for accelerated cooling, the outer wall of the die 4 is installed with a plurality of sliding grooves 401, the outer wall of the sliding groove 401 is installed with a cooling fin 402, and the outer wall of the cooling fin 402 is installed A heat dissipation pipe 403 is installed around the outer wall, and one end of the heat dissipation pipe 403 extends into the interior of the water tank 5. Fans 404 are installed on both inner walls of the bottom mold 2, and a waterproof casing 501 is installed on the inner wall of the water tank 5. A water pump 502 is installed on the bottom wall, a water inlet pipe is installed at the input end of the water pump 502, and one end of the water inlet pipe extends into the interior of the water tank 5, the output end of the water pump 502 is installed with a water outlet pipe, and one end of the water ou...

Embodiment 4

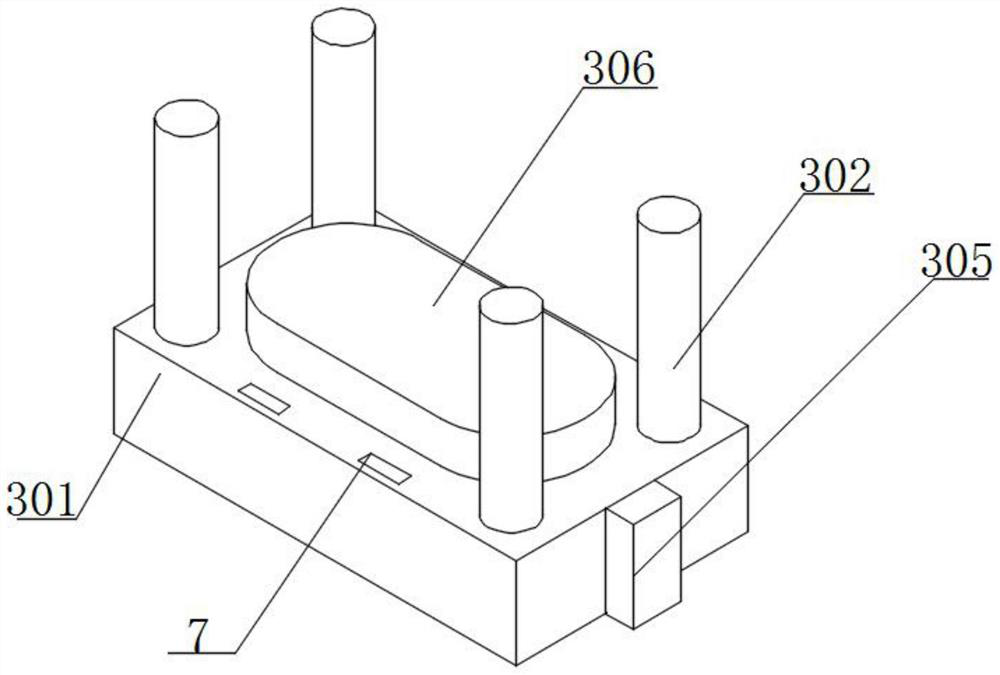

[0046] Example 4: see Figure 7 and Figure 8 , an embodiment provided by the present invention: a convenient reclaiming magnet molding device for accelerated cooling, a support plate 601 is installed on the top of the electric telescopic rod 6, and the top of the support plate 601 is connected with the bottom of the bottom mold 2, the bottom mold A drive motor 604 is installed on the inner wall of A vibration plate 602 is installed on the shaft, a return spring 603 is installed on the outer wall of the vibration plate 602, and one end of the return spring 603 is connected with the bottom of the bottom mold 2. When the mold is taken, the drive motor 604 is activated, and the drive motor 604 drives the rotation rod 605 to rotate , the rotating rod 605 drives the impact rod 606 to rotate, the impact rod 606 drives the impact ball 607 to rotate, the impact ball 607 rotates and hits the vibration plate 602, the vibration plate 602 vibrates after receiving the impact, and the vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com