A led display box locking mechanism and led display box

A technology of LED display screen and locking mechanism, which is applied in the direction of connecting components, mechanical equipment, friction clamping detachable fasteners, etc., which can solve the problem of inability to meet the requirements of fast locking and dismounting between boxes and the operating intensity of engineers and difficult problems, restricting the system construction time, etc., to achieve the effect of seamless splicing, simple and reliable construction, and elimination of splicing edge gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

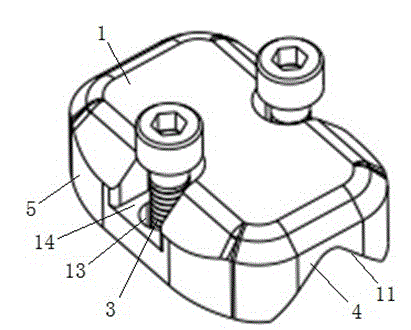

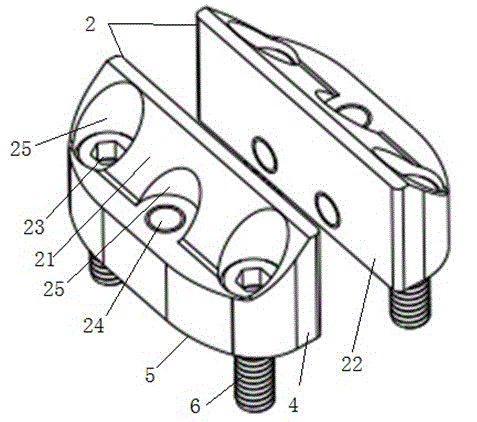

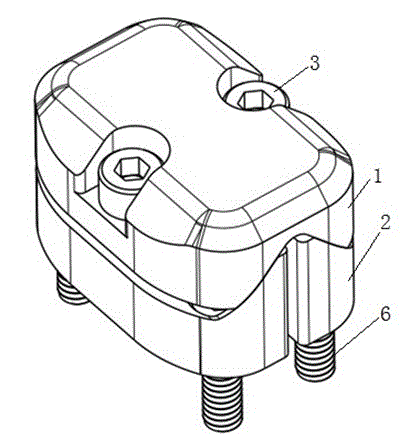

[0026] like Figures 1 to 3 As shown, a LED display box locking mechanism includes a slider 1 and two fixed blocks 2 for relatively installing on the edge of the adjacent unit box of the LED display. The upper end surface of the fixed block 2 is an inclined end surface. 21. The inclined end surfaces 21 of the two fixed blocks 2 are combined to form a triangular inclined end surface. The lower end surface of the slider 1 is provided with a triangular inclined surface 11. The triangular inclined surface 11 on the slider 1 slides down along the triangular inclined end surface to connect the two fixed blocks 2 to each other. Locked, the slider 1 is fixed on the two fixed blocks 2 through the slider connector 3 . The present invention utilizes the principle of force on the inclined plane, and through the interaction between the inclined planes of the slider 1 and the fixed block 2, the two oppositely installed fixed blocks 2 are brought closer to each other so as to reduce the gap ...

Embodiment

[0039] The LED display box locking mechanism described in Embodiment 1 can be applied to the LED display to quickly lock the unit box. Therefore, based on the above LED display box locking mechanism, the present invention also provides an LED display box. LED display cabinet see Figure 4 , The edge of the LED display unit cabinet 7 is provided with a fixed block installation position 71, the fixed block installation position 71 on the adjacent unit cabinet 7 is opposite, and the LED display cabinet locking mechanism is installed on the fixed block installation position 71 .

[0040] Existing unit box body 71 edge itself is provided with vacant hole position, and the present invention can directly utilize this vacant inherent hole position as fixing block mounting position 71, then designs the size of fixing block 2 according to this hole position, just can directly Installing the fixing block 2 on the unit box body 7 does not require any structural improvement on the LED di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com