Inspection shaft

A technology for inspection wells and manhole covers, applied in the field of inspection wells, can solve problems such as difficulty in meeting installation requirements, affecting use functions, and arbitrary adjustment, and achieves the effect of high standardization, easy packaging, and flexibility in adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below in conjunction with the above-mentioned drawings.

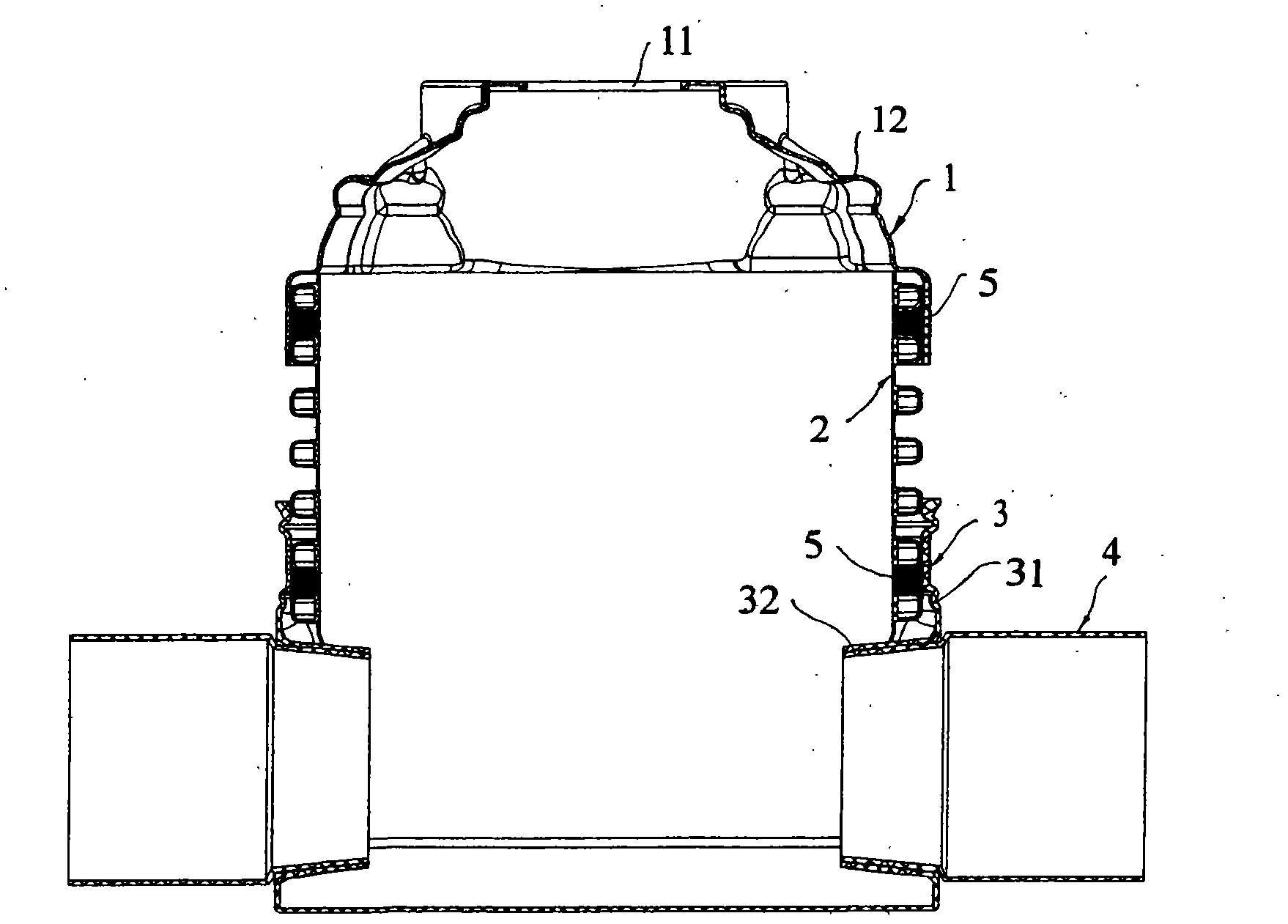

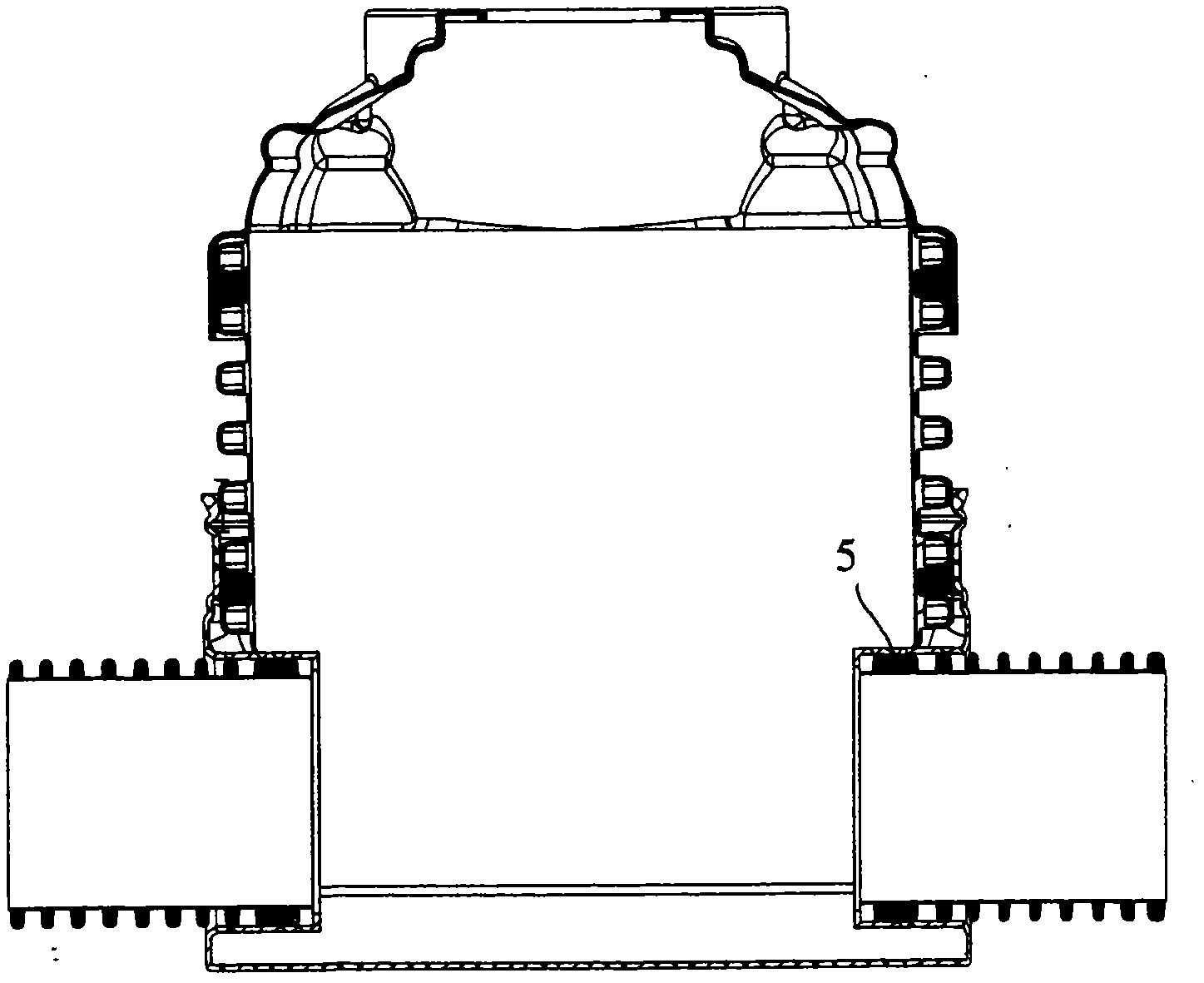

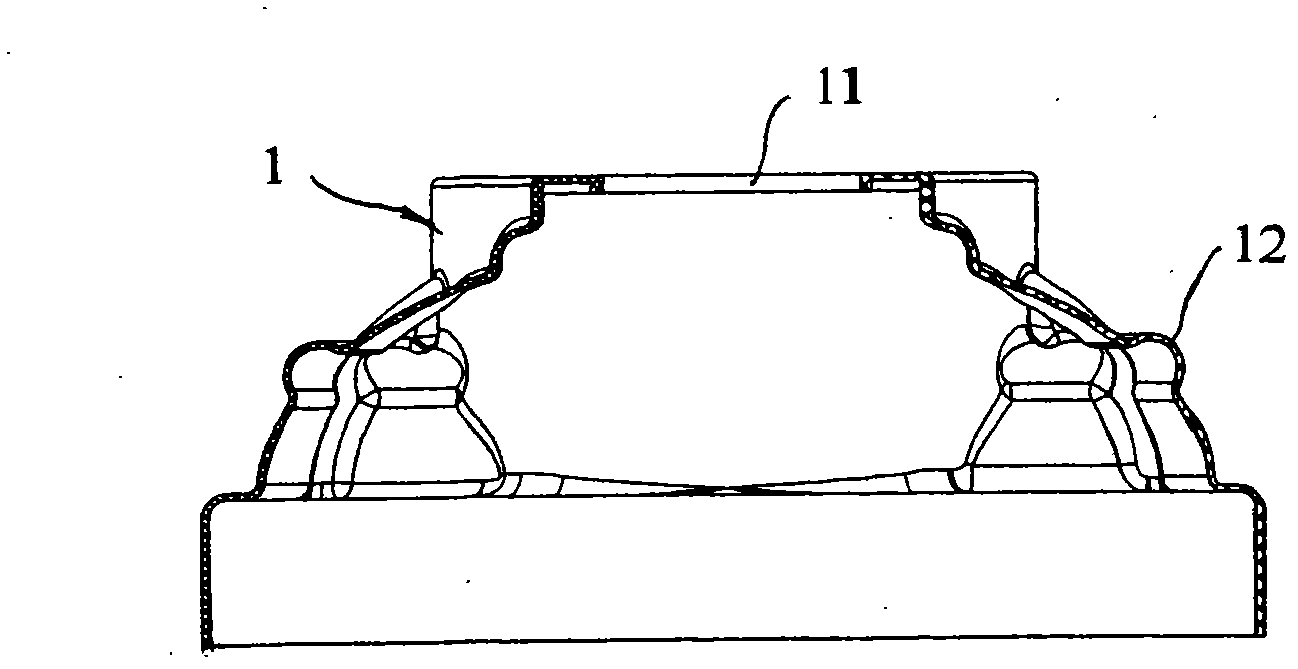

[0021] Such as Figure 1~6 As shown in the figure: 1, manhole cover, 11, observation hole, 12, reinforcing rib, 2, well body, 21, inverted "U" type opening, 3, well seat, 31, reinforcing rib, 32, shoulder, 4. Well arm, 5. Sealing ring.

[0022] An inspection well, such as Figure 1~2 As shown, it is composed of split manhole cover 1, well body 2, well seat 3 and well arm 4, all of which are made of plastic, and are formed at one time by injection molding or rotational molding, and are welded or press-fitted or welded and press-fitted with each other. Fit and seal to form a thin-walled hollow cylinder in the shape of "⊥".

[0023] manhole cover 1 such as image 3 As shown, it is a two-way type, the top surface is provided with an off-center observation hole 11, and the surface is provided with criss-cross reinforcement ribs 12, and the well c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com