Drum washing machine

A drum washing machine and drum technology, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of dirt remaining in the inner and outer drums, and achieve the effect of improving cleanliness, remarkable effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

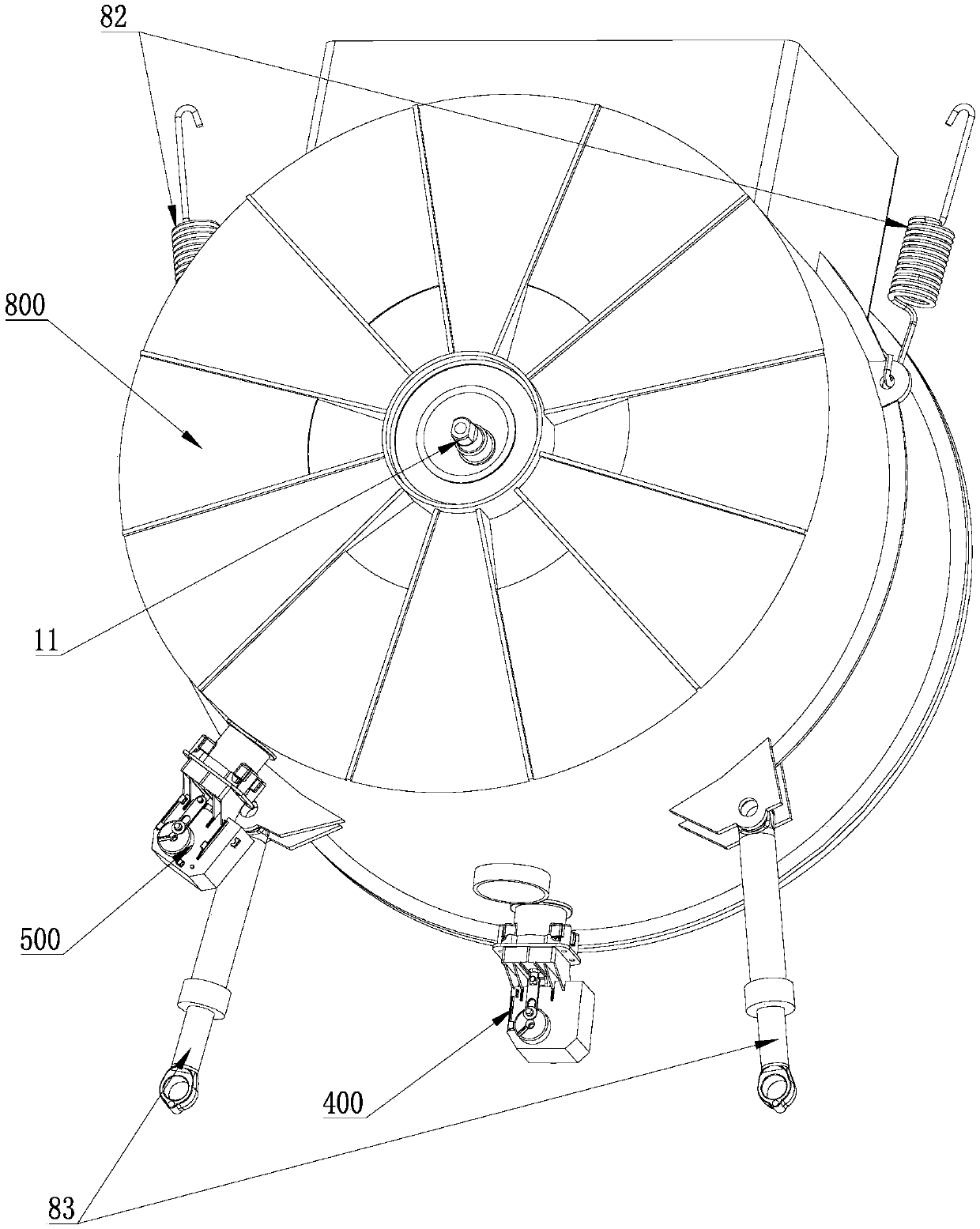

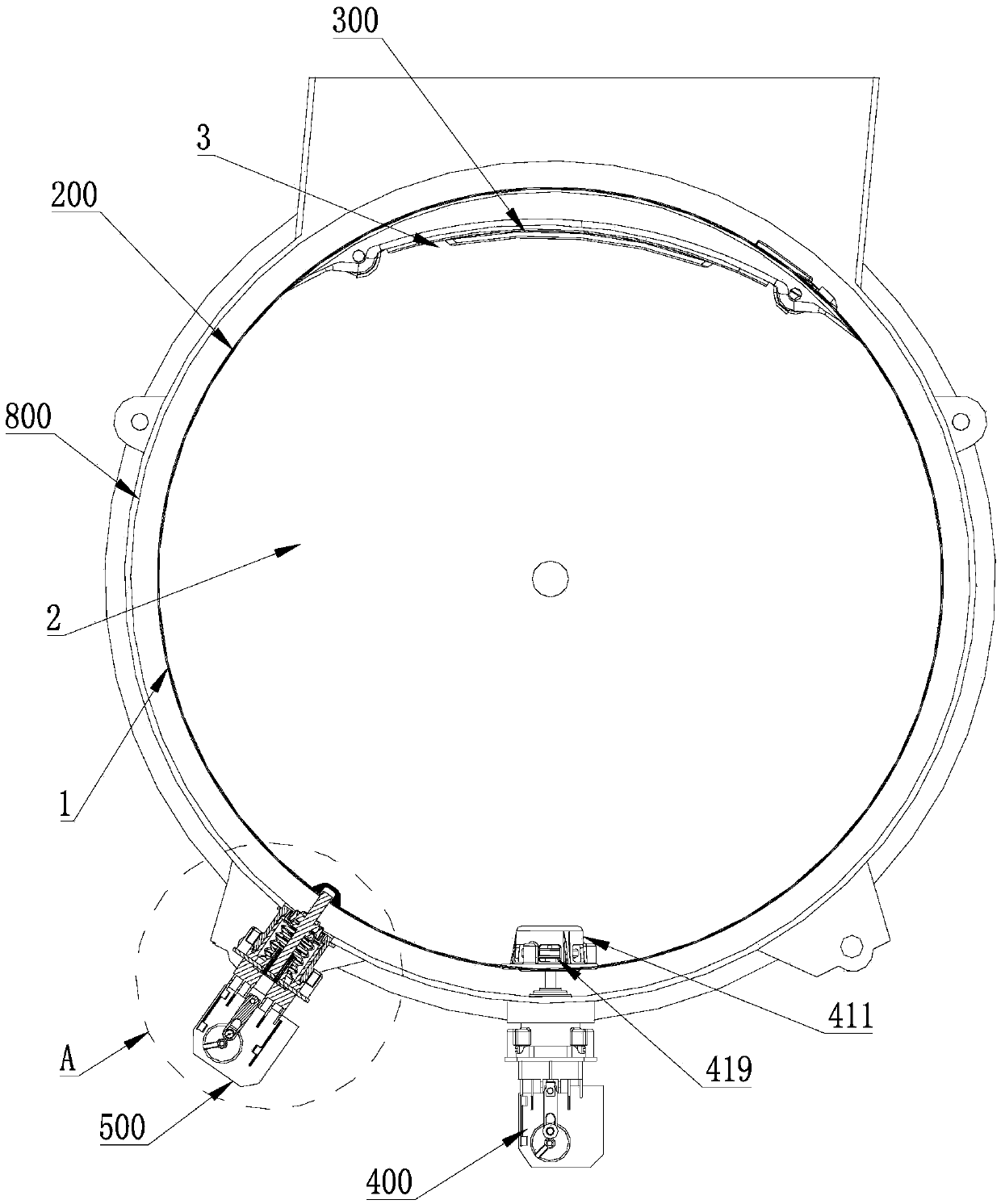

[0062] Such as Figure 1 to Figure 7 As shown, this embodiment introduces a drainage structure of a top-loading drum washing machine. The washing machine includes a drum 800 installed in the housing 100 without dehydration holes. The side wall of the drum 200 is provided with a clothes insertion port 3. 200 is provided with a door cover 300 that can be turned over to open and close the clothes input port; the drum 200 is provided with a drain port 45, and the drain port 45 is provided with a valve core 413 corresponding to the closed opening; a drain structure 400 is also installed in the housing 100, After the drum 200 rotates to a fixed position, the valve core 413 is pushed away to open the drain port 45 .

[0063] By arranging the above-mentioned structure on the drum, after the drum is rotated to a fixed position, the valve core provided at the drain outlet is correspondingly pushed open by the action of the drainage structure, so that the drain outlet of the non-porous d...

Embodiment 2

[0077] Based on the first embodiment above, this embodiment also has the following distinguishing technical features: Figure 1 to Figure 4 As shown, in order to allow the drum to rotate to a fixed position accurately, a positioning structure 500 is also provided on the drum washing machine to limit the rotation of the drum 200 to a fixed position, especially to keep the drum 200 to stop after rotating to a fixed position.

[0078] In this embodiment, the outer circumference of the drum 200 is provided with a positioning groove 55 sunken into the cylinder and a positioning rod 54 that can move telescopically along the radial direction of the drum 200. The positioning rod 54 and the positioning groove 55 are arranged in the same rotating section of the drum 200 to The telescopic end of the positioning rod 54 can extend into the positioning groove 55 correspondingly. Preferably, when the positioning rod 54 is inserted into the positioning slot 55 , the drum 200 rotates to a fixe...

Embodiment 3

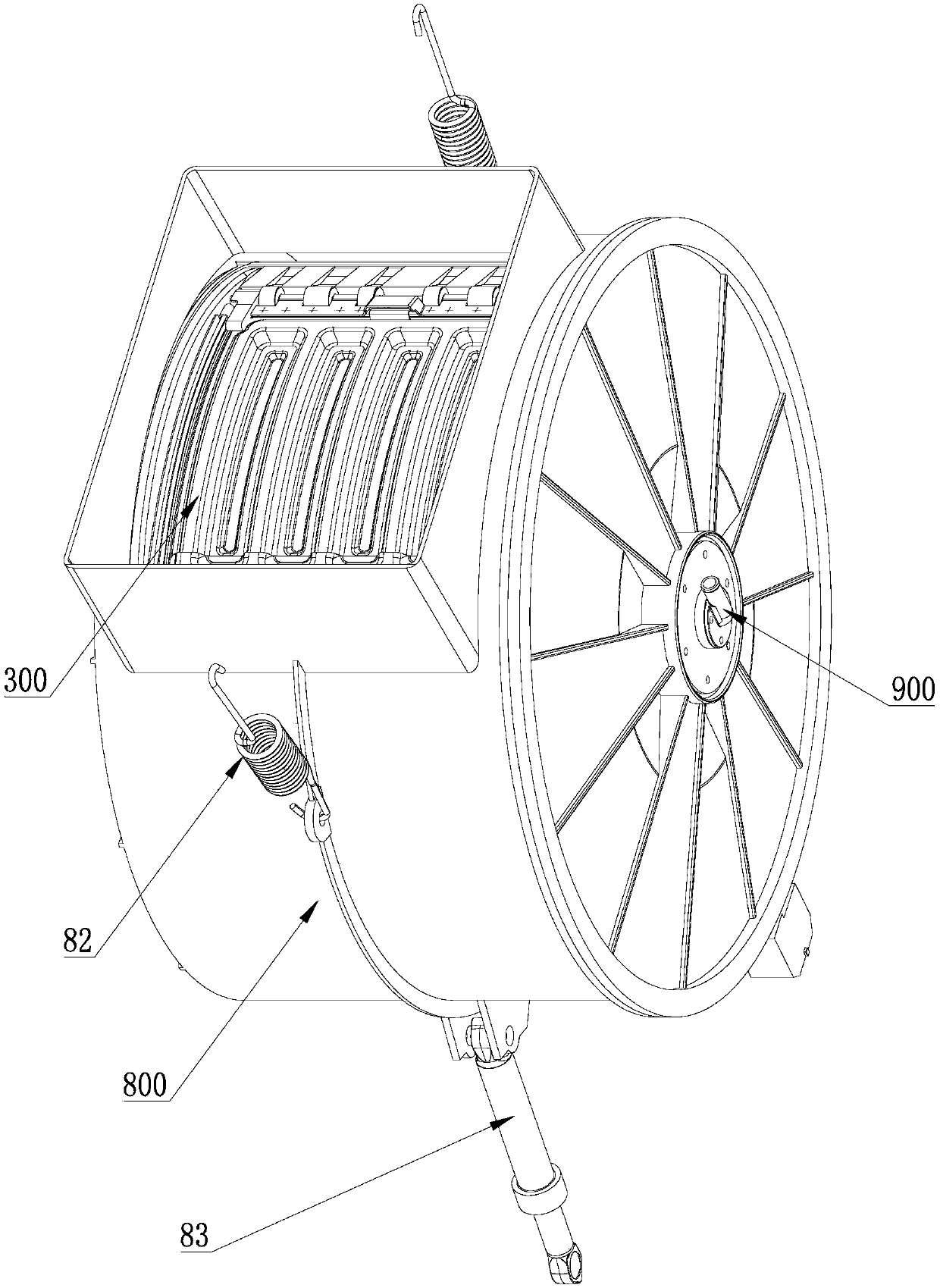

[0090] Such as Figure 8 to Figure 10 As shown, this embodiment introduces a water inlet structure 900 of a top-loading drum washing machine. The washing machine includes a drum 200 installed in the housing 100 without dehydration holes, and the side wall of the drum 200 is provided with a clothes insertion port 3 The drum 200 is provided with a door cover 300 that can be turned over to open and close the clothes inlet; the two ends of the drum 200 are sealed, and the center of the sealed end 2 is connected to the housing 100 through the rotating shaft 11 so that it can rotate relatively. At least one end of the rotating shaft 11 is formed by The hollow sleeve is formed, and the hollow part forms the flow channel 90 and communicates with the water inlet pipe of the washing machine.

[0091] By arranging the above-mentioned water inlet structure at the central rotating shaft of the drum, the use function of the top-loading washing machine to feed water into the non-porous drum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com