Ventilation valve and clothes treating device

A ventilation valve and ventilation hole technology, which can be used in washing devices, other washing machines, textiles and papermaking, etc., can solve the problem of retained dirt and other problems, and achieve the effect of increasing the opening of the valve plate, the effect is remarkable, and the ventilation effect is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

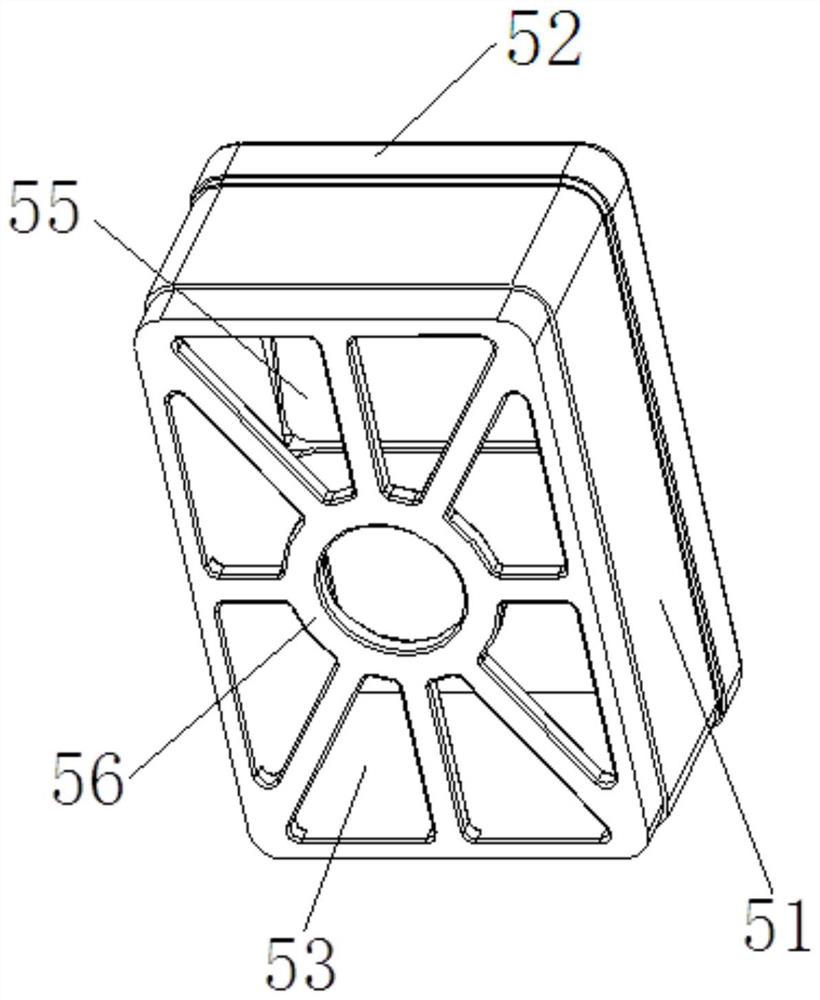

[0059] Such as Figure 1 to Figure 6 As shown, a breathable valve is introduced in this embodiment. The housing 54 of the breathable valve 5 includes a sleeve-shaped valve seat 51, and the inside of the sleeve-shaped valve seat 51 forms a passage 53; A valve cover 52 is buckled at the first end, and a valve plate 55 is disposed at the first end of the sleeve-shaped valve seat 51 , and one side of the valve plate 55 is clamped between the valve cover 52 and the valve seat 51 . The valve plate 55 is in contact with one side of the valve cover 52, and the valve cover 52 provides a limiting force on the valve plate 55, so that the valve plate 55 can only produce relative deformation or displacement to the inside of the valve seat 51, so that the breathable valve 5 constitutes a Valve body structure with one-way ventilation only.

[0060] In this embodiment, the outer periphery of the valve plate 55 is in contact with the inner wall of the channel 53 surrounded by the sleeve-shape...

Embodiment 2

[0068] This embodiment introduces a breathable valve, which is based on the first embodiment above, and also has the following technical features:

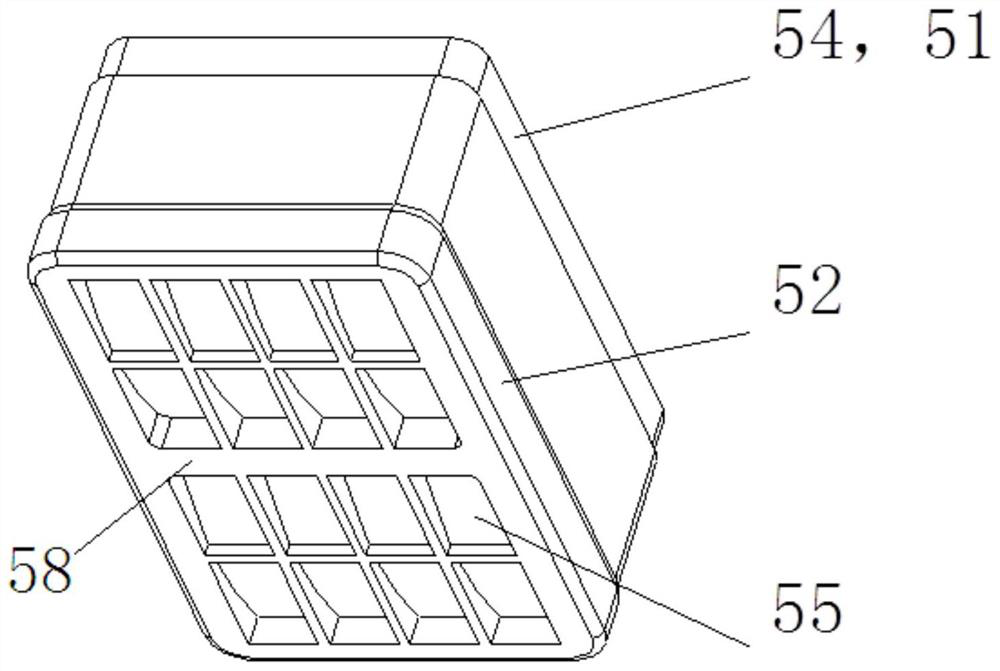

[0069] Such as Figure 7 with Figure 8 As shown, a breathable valve is introduced in this embodiment. The breathable valve 5 includes a sleeve-shaped valve seat 51, and the inside of the sleeve-shaped valve seat 51 forms a passage 53; the first end of the sleeve-shaped valve seat 51 is buckled A valve cover 52 is provided; the first end of the sleeve-shaped valve seat 51 is laid with a plurality of valve plates 55, and each valve plate 55 is spliced to cover the first end of the sleeve-shaped valve seat 51, and each valve plate 55 is in the sleeve-shaped valve seat. The outer peripheral sides of the seat 51 are respectively sandwiched between the valve seat 51 and the valve cover 52 , and each valve plate 55 is suspended near the center side of the sleeve-shaped valve seat 51 .

[0070] By splicing and covering the cross-sect...

Embodiment 3

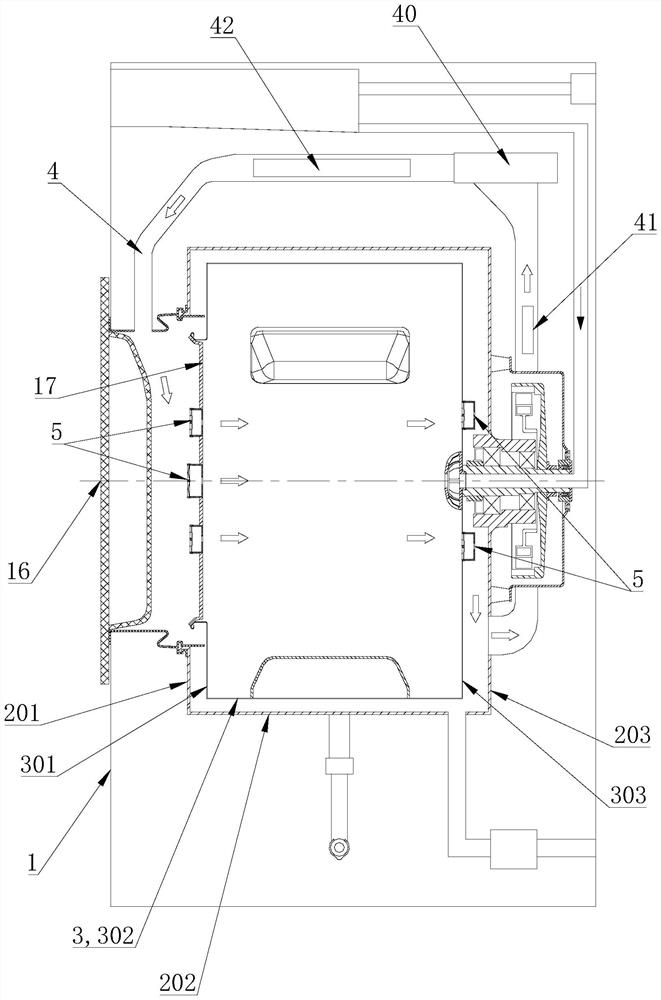

[0082] Such as Figure 1 to Figure 9 As shown, this embodiment introduces a clothes processing device, which includes a drum 3 installed in the casing and forming a sealed water container when the washing machine is in the washing state; the drum 3 is provided with at least one air hole, and each air hole The breather valve 5 described in the above-mentioned embodiment one or two is respectively installed at each place.

[0083] In this embodiment, the casing 54 of the ventilation valve 5 is correspondingly covered and assembled in the ventilation hole, and the outer circumference of the casing 54 is sealed and bonded to the inner wall of the ventilation hole. It communicates with the outside of the drum 3, so that the inside and outside of the drum can achieve the effect of one-way ventilation through the vent valve.

[0084] In this embodiment, the opposite ends of the drum 3 are respectively provided with at least one vent hole equipped with the above-mentioned vent valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com