Construction equipment based on synchronous drilling and precast pile splicing and construction method thereof

A technology of construction equipment and prefabricated piles, which is applied in the direction of drilling equipment and methods, drilling equipment, and infrastructure engineering, etc., which can solve the problems of large floor area, low construction efficiency, and more equipment required, so as to achieve less construction equipment and improve Construction efficiency and the effect of ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

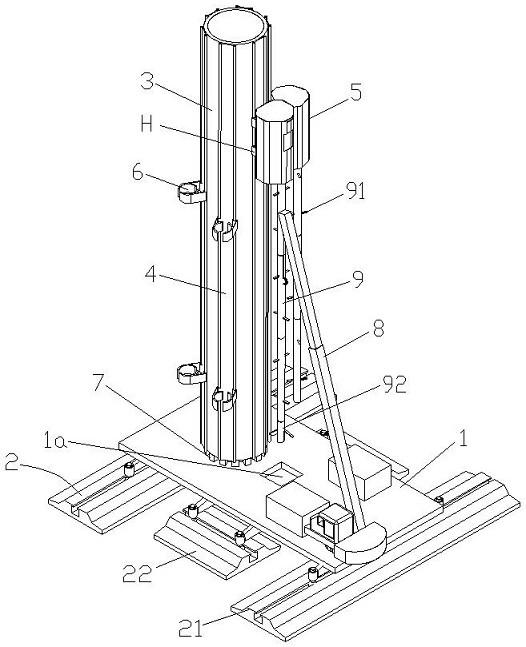

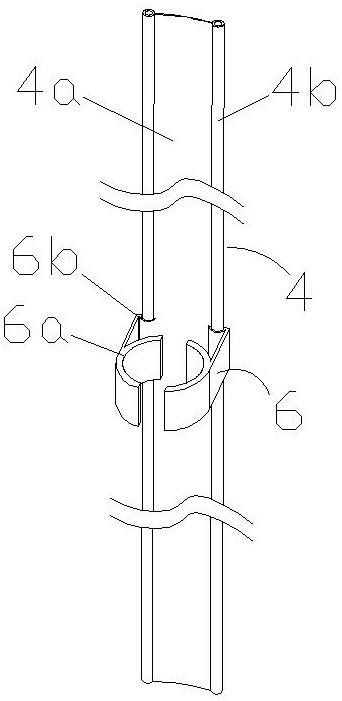

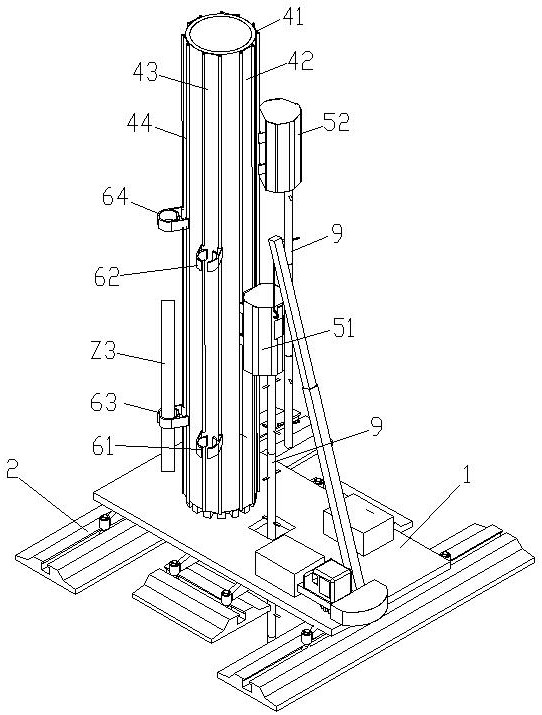

[0048] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0049] Figures 1 to 10 It is a schematic diagram of the structure of the present invention and its construction state.

[0050] The reference signs are: slider H, the first section of prefabricated pile Z1, the second section of precast pile Z2, the third section of precast pile Z3, the fourth section of prefabricated pile Z4, the main platform of equipment 1, the hole for drilling and planting piles 1a , walking gear 2, walking long boat 21, walking short boat 22, main mast 3, track plate 4, curved steel plate 4a, slide rail 4b, No. 1 track plate 41, No. 2 track plate 42, No. 3 track plate 43, No. 4 track plate 44, drilling rig 5, No. 1 drilling rig 51, No. 2 drilling rig 52, pile clamping device 6, arc clip 6a, sliding sleeve 6b, No. 1 pile clamping device 61, No. 2 pile clamping device 62, and No. 3 pile clamping device Pile clamping devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com