I-shaped structure pressure and pull conversion force application apparatus

A technology of force applying device and pressure device, which is applied in the direction of measuring device, truss structure, measuring force, etc., can solve the problems of high cost of universal tensioning machine, unsafe hanging structure, long construction period, etc., and achieve safety in the construction process Fast, overall improvement and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

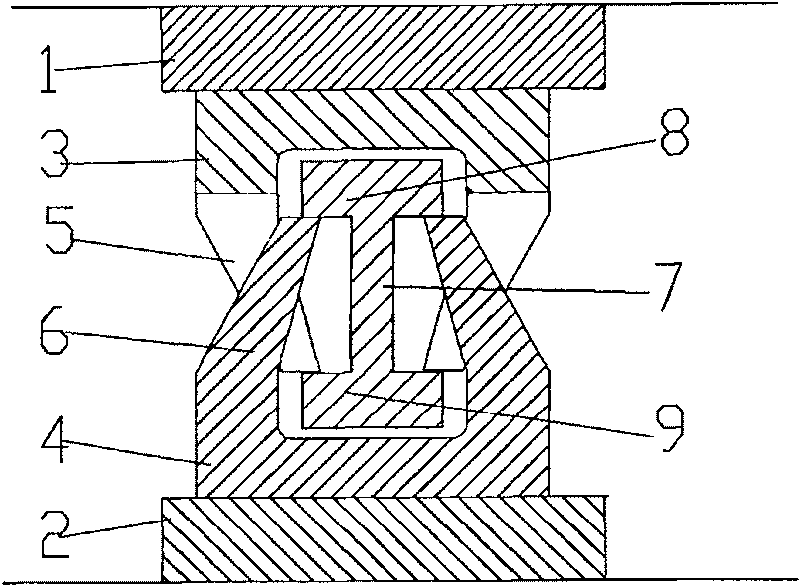

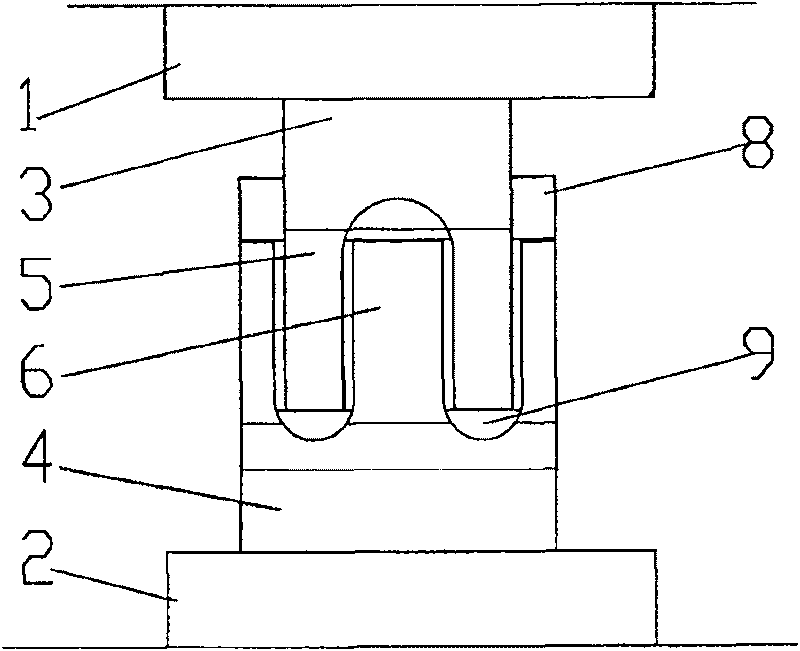

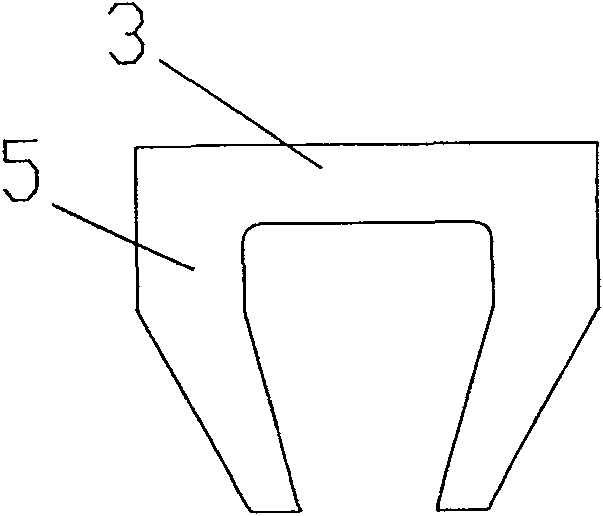

[0019] figure 1 It is a schematic cross-sectional view of the structure of the present invention, figure 2 It is a side view of the present invention, as shown in the figure: the I-shaped structure press-pull conversion force application device of the present invention includes a pressure device, an upper press block 3 and a lower press block 4, and the upper press block 3 and the lower press block 4 are both Longitudinal trough-like structure, the inner sides of the trough-like structure are bent toward the middle to form two top pressure sections, and the corners of the trough-like structure of the upper pressing block 3 and the lower pressing block 4 are arc transitions, eliminating the friction during the compression process. Stress concentration prolongs the service life of the device; when in use, the upper edge plate 8 and the lower edge plate 9 of the I-shaped structure are respectively located in the groove structure of the upper pressing block 3 and the lower pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com