Carpet type quick paving belt, preparation method of carpet type quick paving belt and construction method applying carpet type quick paving belt

A carpet type, paving technology, applied in the direction of adhesive type, film/sheet adhesive, asphalt material adhesive, etc., can solve the problem of affecting road quality and smoothness, effective construction time is short, construction efficiency Low problems, to achieve the effect of improving construction efficiency, shortening construction period, and easy construction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

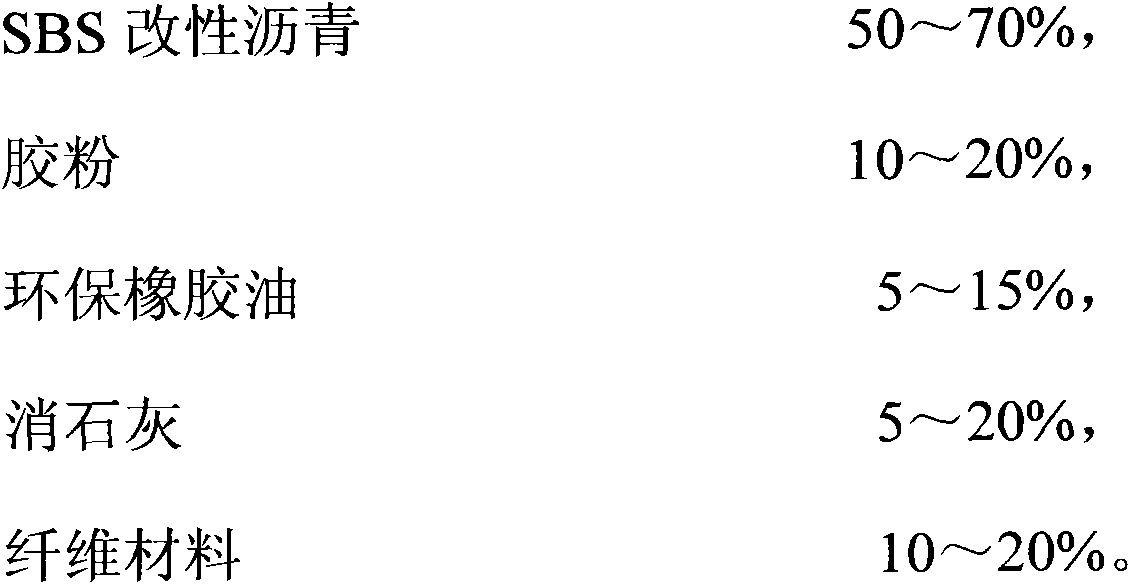

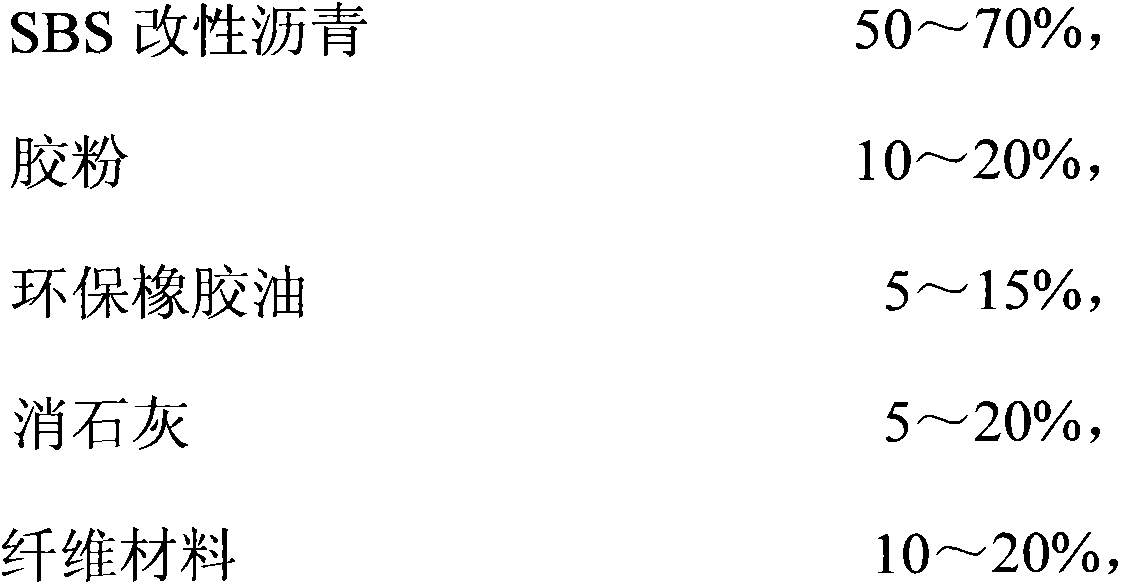

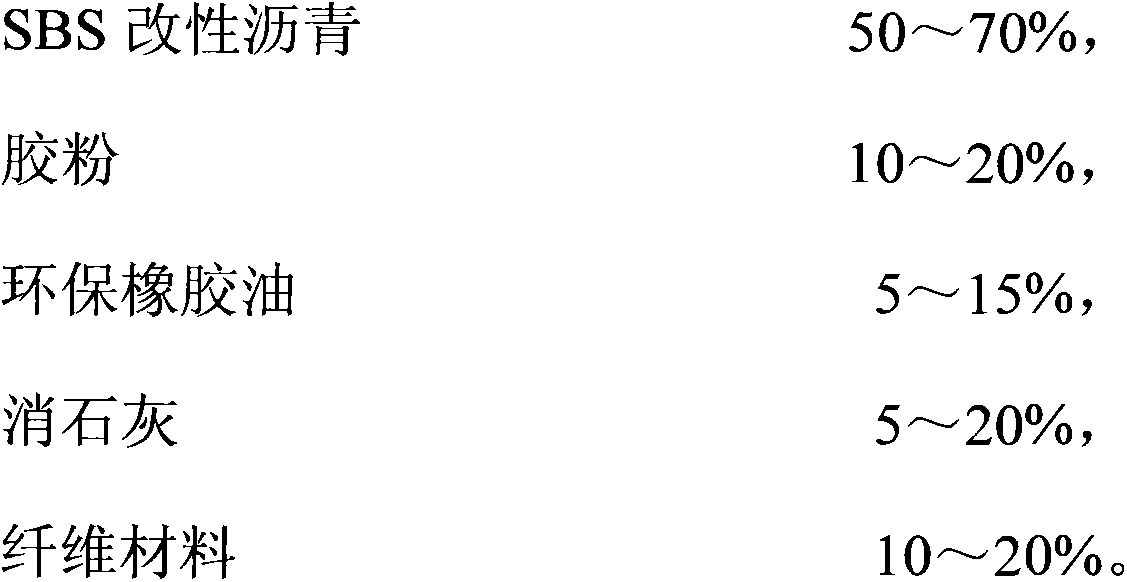

[0034] Embodiment 1: A kind of carpet-type rapid pavement belt provided in this embodiment, which includes a crushed stone surface layer 1 and an adhesive layer 2 attached to the crushed stone surface layer 1, wherein each group of the adhesive layer 2 The components and their mass percentages are as follows: 50% SBS modified asphalt, 20% rubber powder, 15% environmental rubber oil (Tudalen), 5% slaked lime, and 10% fiber material; The rubber powder is preferably 80-mesh rubber powder, the slaked lime is preferably 1000-mesh slaked lime, and the fiber material is preferably fiber fabric or fiber mat.

[0035] The thickness of the adhesive layer 2 is preferably 2-5 mm. The thickness of the gravel surface layer 1 is preferably 1-5 mm.

[0036] The invention provides a carpet-type rapid pavement belt with a reasonable and scientific formula design, which can quickly repair the fatigue cracked road surface, not only has high bonding strength, fast strength molding, good durabilit...

Embodiment 2

[0054] Embodiment 2: a kind of carpet-type rapid pavement belt provided by this embodiment and its preparation and construction method are basically the same as in Example 1, the difference is that each component and its mass percentage in the carpet-type rapid pavement belt are different . Its components and their mass percentages are as follows: 51% of SBS modified asphalt, 11% of rubber powder, 7% of environmental protection rubber oil, 20% of slaked lime, and 11% of fiber material.

Embodiment 3

[0055] Embodiment 3: a kind of carpet-type rapid pavement belt provided by this embodiment and its preparation and construction method are basically the same as in Example 1, the difference is that each component and its mass percentage in the carpet-type rapid pavement belt are different . The components and their mass percentages are as follows: 52% of SBS modified asphalt, 13% of rubber powder, 6% of environmental rubber oil, 9% of slaked lime, and 20% of fiber material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com