Single-slurry blending device for hole drilling and sealing

A single-slurry and hole-sealing technology, which is applied to mixers with rotating stirring devices, transportation, packaging, and dissolution, can solve the problems of ingredients that cannot be stored for a long time, rising construction costs, and insufficient materials. Traditional mixing equipment, improving quality and improving the effect of using quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

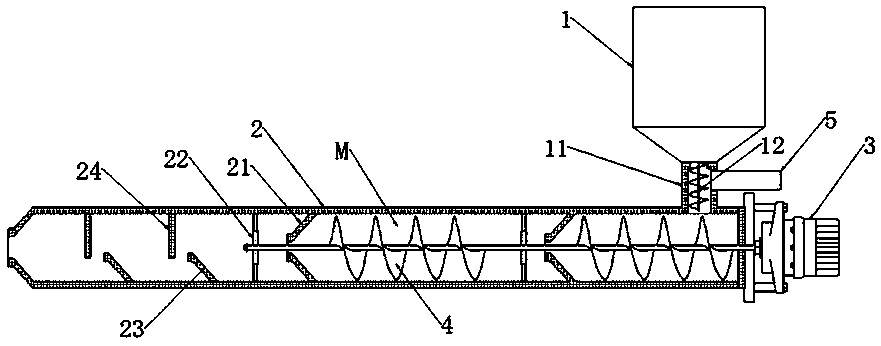

[0033] Such as figure 1 As shown, a single-liquid slurry preparation device for drilling and sealing, the device is composed of a feed tank 1, a mixing pipe 2, a motor 3, a screw propeller 4, and a water inlet pipe 5. The mixing pipe 2 in this scheme is essentially a section of the grouting pipe. The difference is that the diameter of the mixing pipe 2 is larger than that of the grouting pipe. The purpose is that the mixing pipe 2 needs repeated stirring to complete the mixing process. , the required space is larger than that of the grouting pipe, but in terms of specific design, it is optimal that the diameter of the mixing pipe 2 is not more than twice the diameter of the grouting pipe. Among them, the feeding tank 1, the water inlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com