Non-oxidation dehydrogenation treatment technology for austenite stainless steel welding material

An austenitic stainless steel, hydrogen treatment technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve problems such as economic losses, engineering delays, exceeding standards, etc., to reduce H content, avoid economic losses, and reduce hydrogen embrittlement effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

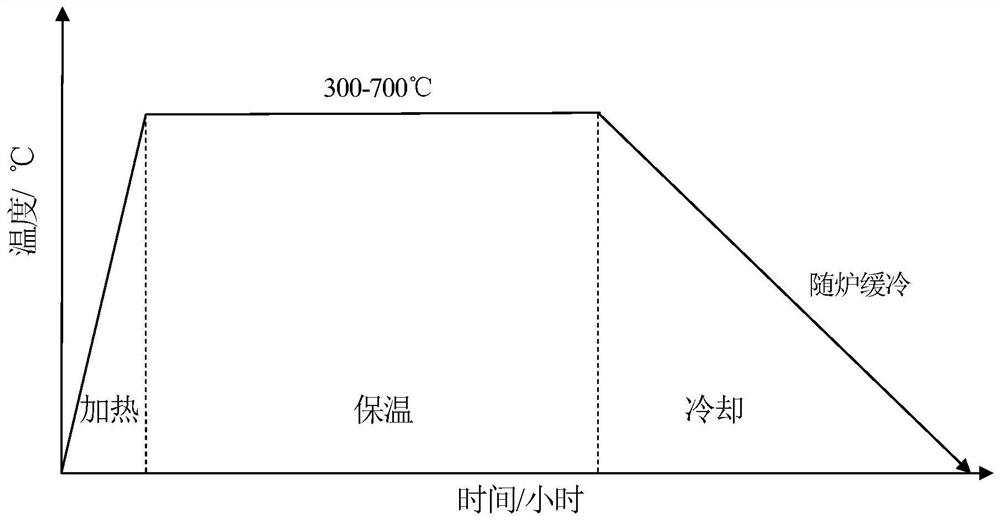

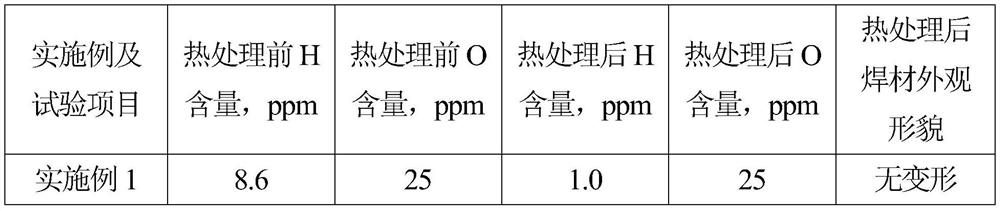

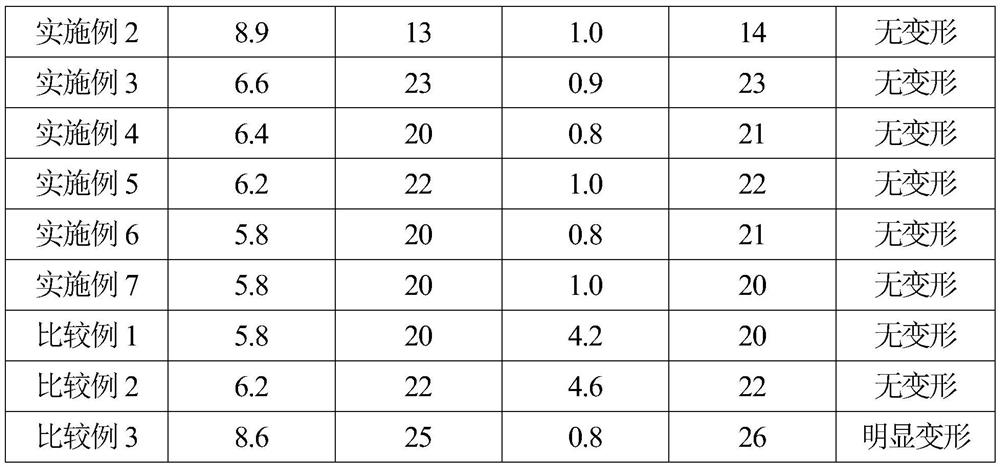

[0025] Heat treatment process: Heat the Φ1.2mm ER316H austenitic stainless steel welding consumable at 4°C / min to 350°C for 20 hours and then cool slowly with the furnace. See Table 1 for the H and O contents of the welding consumables before and after heat treatment and the appearance of the welding consumables after heat treatment.

Embodiment 2

[0027] Heat treatment process: Heat Φ2.0mm ER316H austenitic stainless steel welding consumables at 4°C / min to 400°C for 15 hours and then cool slowly with the furnace. See Table 1 for the H and O contents of the welding consumables before and after heat treatment and the appearance of the welding consumables after heat treatment.

Embodiment 3

[0029] Heat treatment process: Heat the Φ2.4mm ER316H austenitic stainless steel welding consumable at 4°C / min to 450°C for 10 hours and then cool slowly with the furnace. See Table 1 for the H and O contents of the welding consumables before and after heat treatment and the appearance of the welding consumables after heat treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com