A bridge steel q550qe matching flux cored wire

A technology of flux-cored welding wire and bridge, applied in welding equipment, welding medium, welding/cutting medium/material, etc., to achieve the effect of improving comprehensive mechanical properties, improving strength, toughness, crack resistance, and easy slag removal from welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

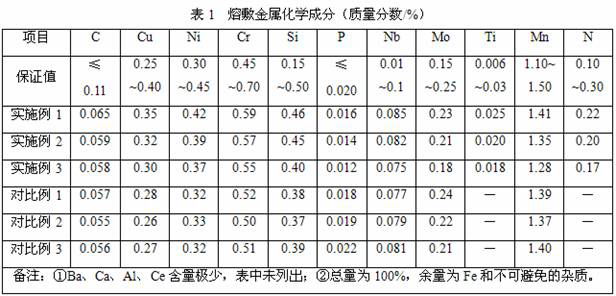

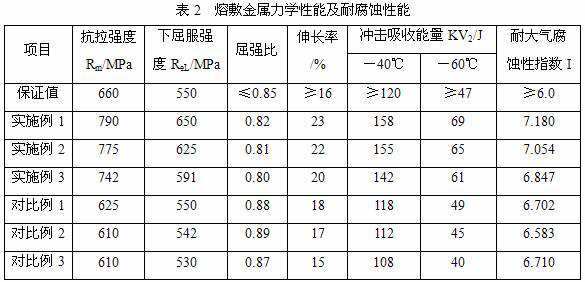

Embodiment 1

[0039] Firstly, the following process is carried out: material selection→powder treatment→powder sieving→powder mixing and powder mixing; then select a low-carbon cold-rolled steel strip with a width of 16mm and a thickness of 0.6mm, and press it into a U shape by a molding machine; Good core powder is filled into the U-shaped groove, and the quality of the core powder accounts for 25% of the mass of the flux-cored wire; then the opening of the U-shaped groove is closed to form an O shape, so that the core is wrapped in it, and the wire drawing machine is drawn one by one. Drawing and reducing the diameter to obtain a welding wire of Ф3.2mm, namely the bridge steel Q550qE matching flux-cored welding wire of the present invention.

[0040] The composition and dosage of the drug core are calculated by mass percentage: nano titanium nitride powder 1.8%, nano cerium oxide 1.2%, FeAl8Ba12Ca6Si40 silicon calcium barium aluminum alloy 0.5%, Nb powder 0.35%, Cr powder 1.2%, Ni powder ...

Embodiment 2

[0042] Firstly, the following process is carried out: material selection→powder treatment→powder sieving→powder mixing and powder mixing; then select a low-carbon cold-rolled steel strip with a width of 16mm and a thickness of 0.6mm, and press it into a U shape by a molding machine; Good core powder is filled into the U-shaped groove, and the quality of the core powder accounts for 25% of the mass of the flux-cored wire; then the opening of the U-shaped groove is closed to form an O shape, so that the core is wrapped in it, and the wire drawing machine is drawn one by one. Drawing and reducing the diameter to obtain a welding wire with a diameter of Ф1.8mm, that is, the bridge steel Q550qE matching flux-cored welding wire of the present invention.

[0043] The composition and dosage of the drug core are calculated by mass percentage: 1.3% of nano-titanium nitride powder, 0.8% of nano-cerium oxide, 0.35% of FeAl8Ba12Ca6Si40 silicon-calcium-barium-aluminum alloy, 0.28% of Nb powd...

Embodiment 3

[0045] Firstly, the following process is carried out: material selection→powder treatment→powder sieving→powder mixing and powder mixing; then select a low-carbon cold-rolled steel strip with a width of 16mm and a thickness of 0.6mm, and press it into a U shape by a molding machine; Good core powder is filled into the U-shaped groove, and the quality of the core powder accounts for 25% of the mass of the flux-cored wire; then the opening of the U-shaped groove is closed to form an O shape, so that the core is wrapped in it, and the wire drawing machine is drawn one by one. Drawing and reducing the diameter to obtain a Ф1.2mm welding wire, that is, the bridge steel Q550qE matching flux-cored welding wire of the present invention.

[0046] The composition and dosage of the drug core are calculated by mass percentage: 0.8% of nano titanium nitride powder, 0.5% of nano cerium oxide, 0.2% of FeAl8Ba12Ca6Si40 silicon calcium barium aluminum alloy, 0.2% of Nb powder, 0.8% of Cr powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com