Hot-rolled round steel produced by continuous casting and production method thereof

A production method and round steel technology, which is applied in the field of iron and steel smelting, can solve the problems of increased central porosity of round steel, inner surface defects, and reduced performance and grade of hot-rolled round steel, so as to achieve low central porosity and reduce central porosity , the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

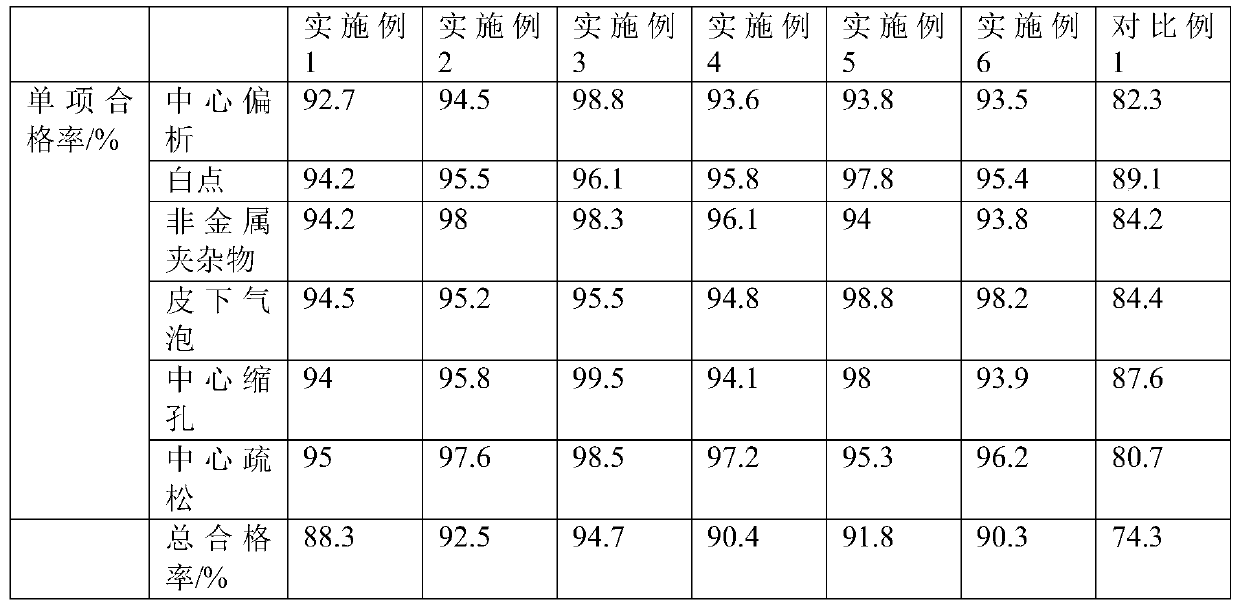

Embodiment 1

[0040] A hot-rolled round steel produced by continuous casting, which is produced by comprising the following steps:

[0041] S1 Smelting: Put molten iron and steel scrap into the converter, carry out conventional top-bottom compound blowing and control the blowing oxygen pressure to 0.8MPa, when the tapping temperature is 1610°C, detect the carbon content in the molten steel, and control the carbon at the end of the converter to 0.15wt %, then tap steel into the ladle;

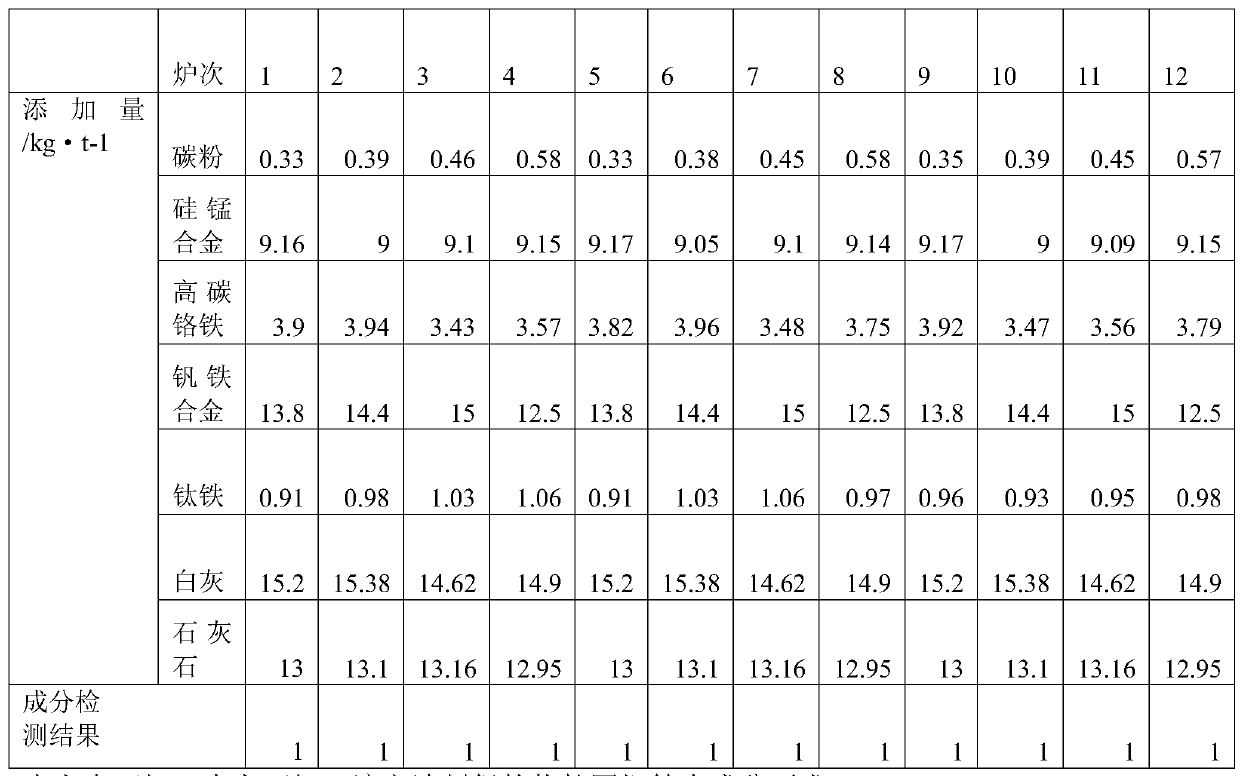

[0042] S2 deoxidation alloying: The converter blows argon throughout the process of tapping into the ladle. When the molten steel in the ladle reaches 1 / 4 of the maximum capacity of the molten steel in the ladle, add carbon powder of 0.33kg / ton of steel and 9.00kg / ton of steel into the ladle. Silicon-manganese alloy of steel, high-carbon ferrochromium of 3.43kg / ton of steel, ferrovanadium alloy powder of 15.00kg / ton of steel, and the above-mentioned added materials are added before the molten steel in the lad...

Embodiment 2

[0054] On the basis of embodiment 1, the electromagnetic stirring of the crystallizer in S4 molten steel casting is improved, and the improvement is that the stirring zone of the electromagnetic stirring of the crystallizer is divided into a first stirring zone and a second stirring zone, and the first stirring zone is located between the ultrasonic zone and the second stirring zone. Between the buffer zones, the circulation direction of the first stirring zone is horizontal and it starts intermittently, and the second stirring zone is located at the entrance of the crystallizer and the horizontal axis of the stirring circulation direction is parallel to the pulling direction of the slab.

Embodiment 3

[0056] On the basis of Example 2, the electromagnetic stirring of the mold in S4 molten steel casting is improved, and the third stirring zone and the fourth stirring zone are added. The third stirring zone is located at the exit of the mold and the axis of the stirring circulation direction is perpendicular to the pulling direction of the slab. , the fourth stirring zone is located behind the fourth stirring zone and the axis of its stirring circulation direction is parallel to the pulling direction of the slab.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com