A kind of smelting method of non-quenched and tempered steel

A smelting method and technology of non-quenched and tempered steel, which is applied in the field of metallurgy, and can solve problems such as secondary oxidation of molten steel, affecting the fluidity of molten steel in the continuous casting process, and the purity of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

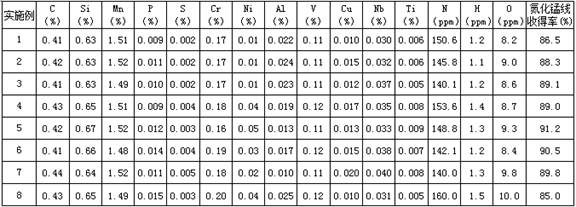

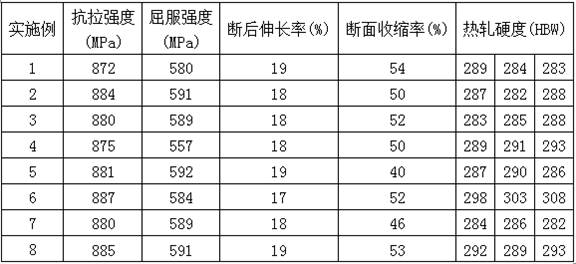

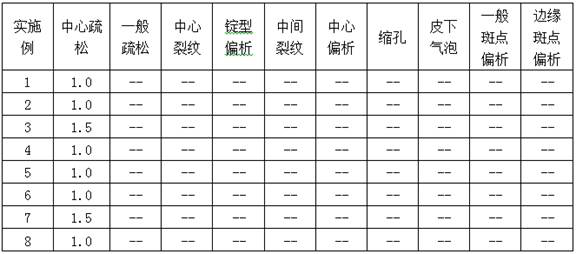

Examples

Embodiment 1

[0024] The chemical composition and mass percentage of the non-quenched and tempered steel in this example are shown in Table 1. The smelting method includes converter smelting, LF refining, VD vacuum treatment, and continuous casting process. The specific process steps are as follows:

[0025] (1) Converter smelting: Nitrogen is blown at the bottom during the whole process of converter smelting, and the nitrogen consumption is 25Nm 3 / t steel; converter high-draw carbon tapping, tapping C: 0.10%, to avoid molten steel over-oxidation, steel core aluminum 2.7kg / t steel, silicon-manganese alloy 17kg / t steel, ferrosilicon 2.5kg / t steel are added in sequence during the tapping process / t steel, white ash 5.4㎏ / t steel, refining slag 4.3㎏ / t steel, slag is strictly prohibited during the tapping process, and aluminum wire is fed 0.56㎏ / t steel after tapping;

[0026] Lime is high-quality refined lime, its composition and performance indicators are: CaO: 92%, MgO: 4.7%, SiO 2 : 1.6%, S...

Embodiment 2

[0033] The chemical composition and mass percentage of the non-quenched and tempered steel in this example are shown in Table 1. The smelting method includes converter smelting, LF refining, VD vacuum treatment, and continuous casting process. The specific process steps are as follows:

[0034] (1) Converter smelting: Nitrogen is blown at the bottom during the whole process of converter smelting, and the nitrogen consumption is 27Nm 3 / t steel; converter high-draw carbon tapping, tapping C: 0.09%, to avoid molten steel peroxidation, steel core aluminum 2.2㎏ / t steel, silicon-manganese alloy 16.5㎏ / t steel, ferrosilicon 1.8㎏ are added in sequence during the tapping process / t steel, white ash 5.7㎏ / t steel, refining slag 4.7㎏ / t steel, slag is strictly prohibited during the tapping process, and aluminum wire is fed 0.63㎏ / t steel after tapping;

[0035] The lime is high-quality refined lime, and its composition and performance indicators are: CaO: 91%, MgO: 4.2%, SiO 2 : 1.9%, S: 0...

Embodiment 3

[0042] The chemical composition and mass percentage of the non-quenched and tempered steel in this example are shown in Table 1. The smelting method includes converter smelting, LF refining, VD vacuum treatment, and continuous casting process. The specific process steps are as follows:

[0043] (1) Converter smelting: Nitrogen is blown at the bottom during the whole process of converter smelting, and the nitrogen consumption is 24Nm 3 / t steel; converter high-draw carbon tapping, tapping C: 0.085%, to avoid molten steel overoxidation, steel core aluminum 2.4kg / t steel, silicon-manganese alloy 17.5kg / t steel, ferrosilicon 1.2kg are added in sequence during tapping / t steel, white ash 5.9㎏ / t steel, refining slag 4.8㎏ / t steel, slag is strictly prohibited during the tapping process, and aluminum wire is fed 0.65㎏ / t steel after tapping;

[0044] The lime is high-quality refined lime, its composition and performance indicators are: CaO: 91.5%, MgO: 4.4%, SiO 2 : 1.5%, S: 0.026%, ig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com