A kind of marine submerged arc welding combined sintering flux and preparation method thereof

A combination of sintering and flux technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problem that it is difficult to obtain weld seam mechanical properties, weld seam shape and mechanical properties, and back weld seam Forming and other problems, to improve the mechanical properties of the weld metal, to avoid the thick structure of the weld, and to increase the use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

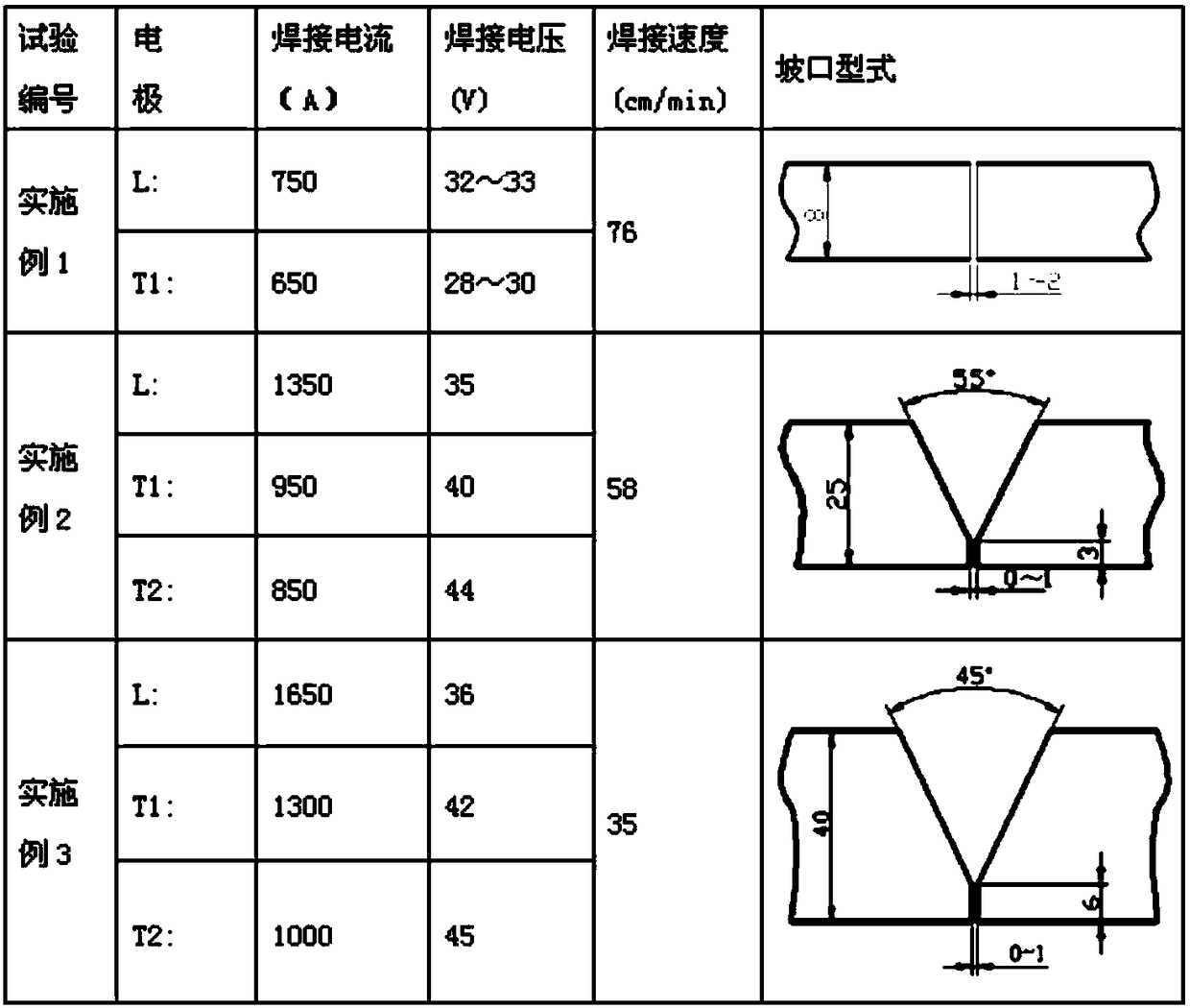

Examples

Embodiment Construction

[0038] The surface flux of each embodiment is prepared by surface solder and 20% water glass of surface solder weight, and pad solder is prepared by surface solder and 20% water glass of surface solder weight; Concrete preparation method is as follows:

[0039] (1) Preparation of surface flux

[0040] Proportionally weigh each raw material in the surface solder, sieve the actual required particle size, and then make ingredients according to the weight ratio. After fully mixing, add water glass for wet stirring, and then use a granulator to granulate. The wet granular flux is dried at 200-300°C in a low-temperature furnace, and the dried flux is sieved to 10-50 meshes, then sintered at a high temperature of 400-500°C in a high-temperature furnace, and finally sieved and cooled. Put it into a vacuum bag with moisture-proof packaging for welding production;

[0041] (2) Preparation of pad flux

[0042] Proportionally weigh the raw materials in the pad solder and sieve them acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com