A kind of high-strength closed-cell aluminum alloy foam and its preparation method

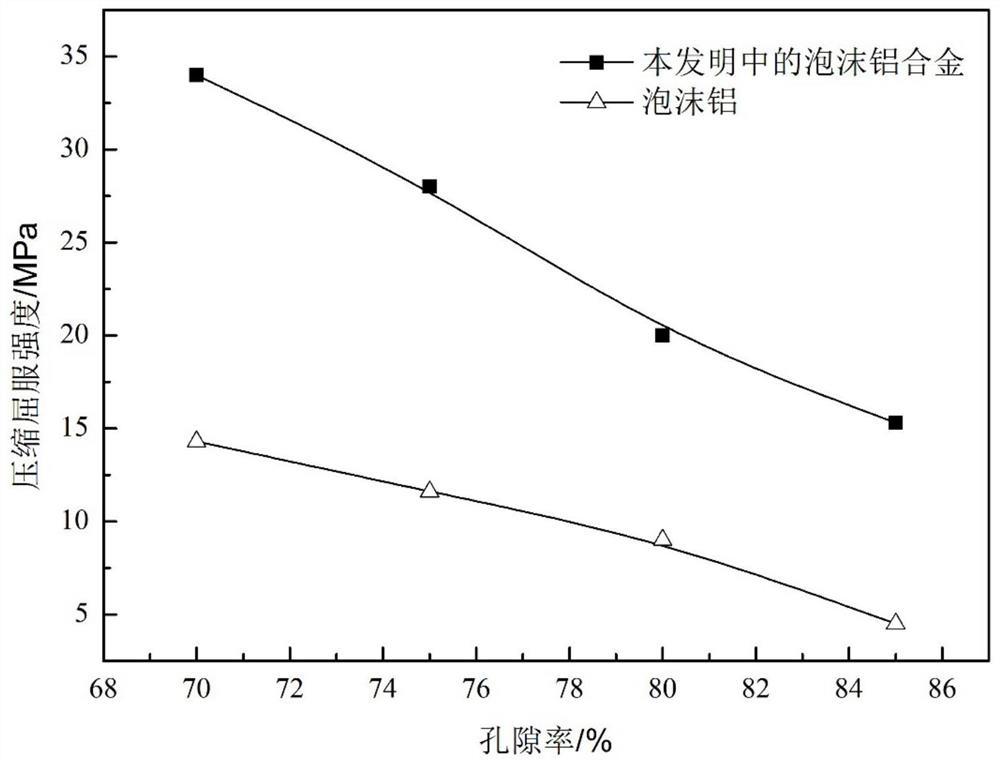

A foamed aluminum alloy and closed-cell foam technology, which is applied in the field of metal materials, can solve the problems of low strength of closed-cell foamed aluminum, and achieve the effects of increasing strength, improving purity, and increasing compressive yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this implementation, the chemical composition and weight percentage of the closed-cell foamed aluminum alloy are: Zn: 6.2%, Cu: 0.8%, Mg: 0.4%, Ca: 1.8%, Y: 0.06%, impurities equal to 0.2%, and the balance for Al.

[0034] The steps for preparing this high-strength closed-cell aluminum alloy foam are as follows:

[0035] Step 1: According to the mass ratio, add aluminum, Zn, Cu, and Y components in the melting furnace, wherein aluminum and Zn are in the form of pure aluminum and pure zinc, and Cu and Y are in the form of AlCu50 and AlY2 master alloys respectively. The alloy components are overheated to 875°C, and after all the components are melted, stir for 30 minutes;

[0036] Step 2: Vacuum pump the aluminum melt, set the vacuum degree to 700Pa, and pump for 14 minutes;

[0037] Step 3: Cool down the aluminum alloy melt to 710°C, add 0.4% Mg, and stir for 6 minutes;

[0038] Step 4: Transfer the aluminum alloy melt to a foaming furnace, control the temperature ...

Embodiment 2

[0041] In this implementation, the chemical composition and weight percentage of the closed-cell foamed aluminum alloy are: Zn: 8.0%, Cu: 1.0%, Mg: 0.5%, Ca: 2.3%, Y: 0.08%, impurities equal to 0.15%, and the balance for Al.

[0042] The steps for preparing this high-strength closed-cell aluminum alloy foam are as follows:

[0043] Step 1: According to the mass ratio, add aluminum, Zn, Cu, and Y components in the melting furnace, wherein aluminum and Zn are in the form of pure aluminum and pure zinc, and Cu and Y are in the form of AlCu50 and AlY2 master alloys respectively. Overheat the alloy components to 885°C, and stir for 35 minutes after all the components are melted;

[0044] Step 2: Carry out vacuum pumping treatment on the aluminum melt, set the vacuum degree to 900Pa, and pump for 11 minutes;

[0045] Step 3: Cool down the aluminum alloy melt to 705°C, add 0.5% Mg, and stir for 7 minutes;

[0046] Step 4: Transfer the aluminum alloy melt to a foaming furnace, cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive yield strength | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com