Method for uniformly mixing powdery metals in real time, and metal 3D printing method and device

A technology of uniform mixing and 3D printing, which is applied in the field of real-time uniform mixing of powdered metals and uniform mixing of powdered metals. It can solve the problems of defective content of mixed elements, affecting the quality of forming, and inconsistent expected designs, so as to improve the uniformity of powder components, Avoid element content defects and avoid the effect of uneven composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

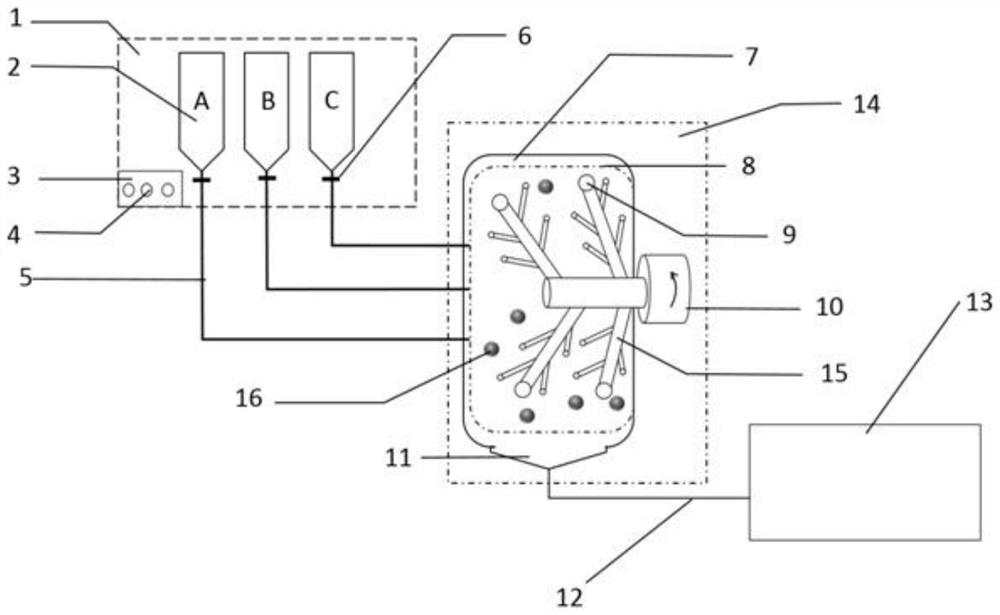

[0049] The invention provides a method for uniformly mixing powdery metals in real time. The method for uniformly mixing powdery metals in real time comprises the following steps:

[0050] 1) Determine the type of powdered metal to be mixed, the particle size of the powdered metal, and the mixing ratio of different types of powdered metal according to actual needs; the types of powdered metal include at least two;

[0051] 2) Use inert gas to send different types of powdered metals into the mixing zone for stirring and mixing until they are evenly stirred, specifically:

[0052] 2.1) Select inert gas;

[0053] 2.2) According to the mixing ratio of different types of powdered metals, the flow rate of the inert gas is adjusted in real time, and different types of powdered metals are sent into the mixing area through the inert gas;

[0054] 2.3) Stir the different types of powdered metals sent into the mixing zone until the different types of powdered metals are mixed evenly in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com