Construction Method of Overturning the Arch Rib of the Arch Bridge Using the Cable Crane

A technology of a cable crane and a construction method, which is applied in the directions of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as damage to arch-ribbed steel pipes, and achieve the effects of construction safety, saving construction equipment and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

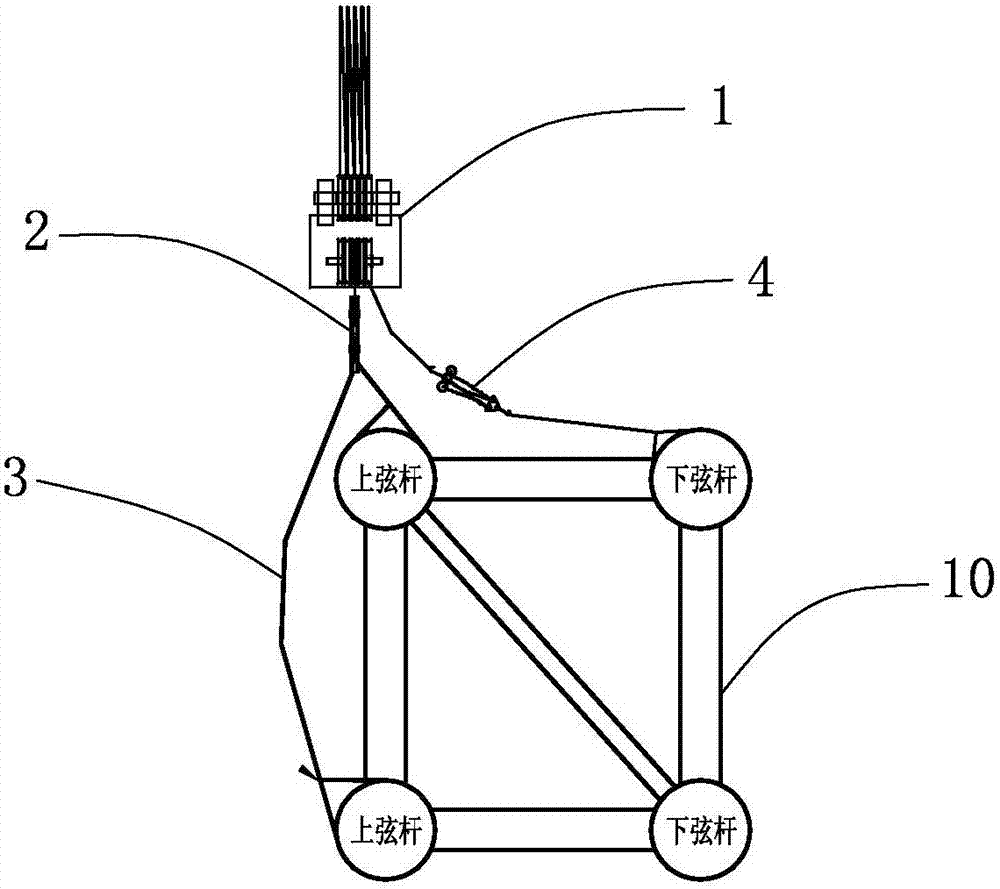

[0018] The method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] In the present invention, the inverted arch rib segment is firstly transported to the lower part of the cable suspension point. The cable crane is a crane for hoisting the arch rib segments on the bridge. The present invention adopts the cable crane for hoisting the arch rib segments to flip the arch ribs, which saves the car cranes and gantry cranes used to flip the arch ribs in the prior art. It is hoisted directly to the bridge by a cable hoist, which simplifies the process and reduces the cost.

[0020] The transportation of the arch rib segment can be carried out by laying the vertical track and the transverse track, and using the vertical and horizontal track flat car to transport the arch rib segment from the pre-assembled position to the lifting point of the crane.

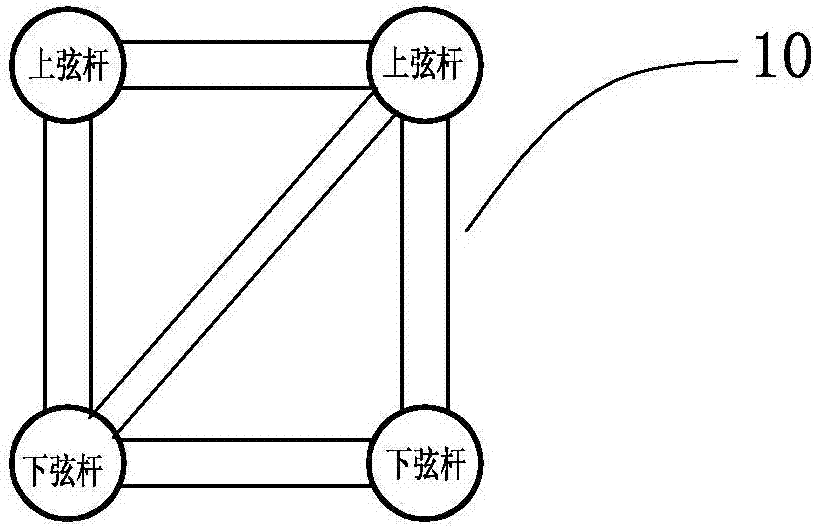

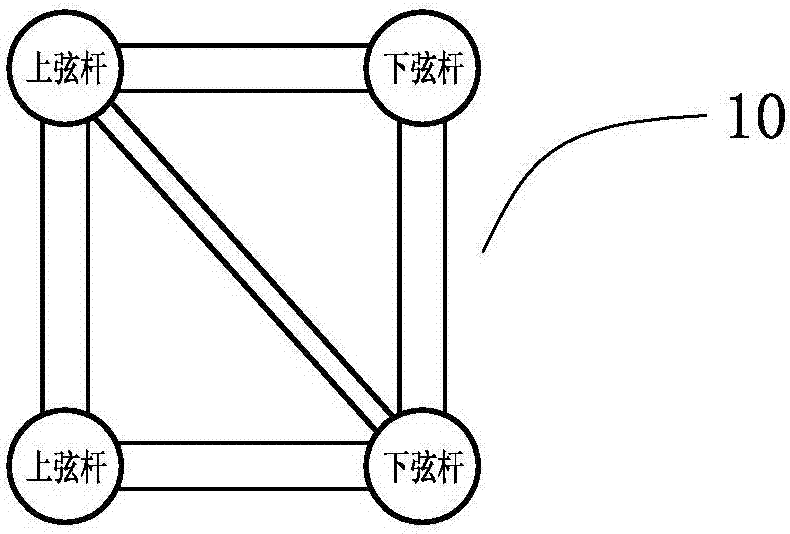

[0021] Such as image 3 As shown, after the arch rib segment 10 to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com