Non-water-stopping grouting repairing method for expansion joint of sewage treatment structure

A sewage treatment and repair method technology, applied in the field of expansion joint repair, can solve the problems of large construction area, many construction equipment, high repair cost, etc., and achieve the effect of small construction work and less construction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

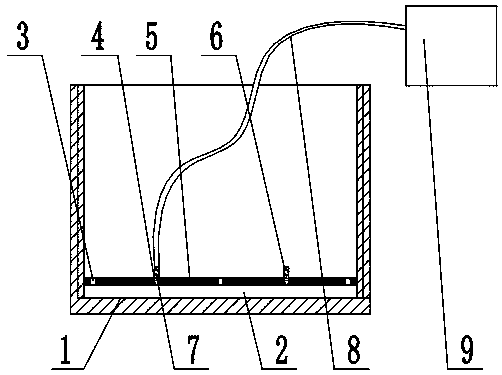

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

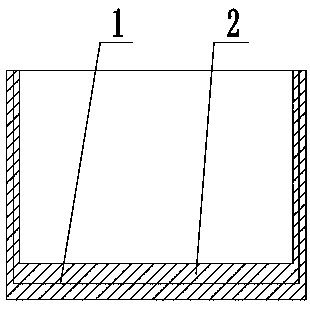

[0029] Such as figure 2 As shown, the present invention discloses a method for repairing expansion joints of sewage treatment structures without stopping water grouting, comprising the following steps:

[0030] S1. Clean the caulking material above the waterstop of the expansion joint to be repaired along the length direction of the expansion joint to be repaired to form a caulk;

[0031] The caulking material above the waterstop can be removed with a hammer and chisel. During the removal process, all caulking materials need to be removed, especially the concrete interface with the seam wall. If the thickness of the bottom plate of the entire sewage treatment structure is 500mm, the waterstop is usually installed at a depth of 250mm, so the length of the chisel into the caulking can be used to determine the cleaning depth. After cleaning the joints, use a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com